Injector Flow vs Pump Flow

#1

Thread Starter

I have a gauge for that

iTrader: (42)

Joined: Jan 2006

Posts: 16,266

Likes: 394

From: Huntsville, AL

UPDATE 2/9/2015

I got an email from a guy asking about fuel line size effects so I added that part in. If you open the spreadsheet is in the top middle. Basically you look up the max volume of fuel you will flow from the tables below, or type it into one of the quick calculators on the right, to get the flow volume (L/hr). Look on the little AN table size for the different inner diameters of AN hoses. Stock 3/8" fuel line has an ID of 0.310" I believe. Also input the length of the line from the fuel pumps to the rail.

The Fitting section right below that takes into account pressure loss from the fittings you use. A union is any connection point is anywhere there is a fitting. Type in the number of different fitting types you have.

This is based on a standard fluid dynamics type calculation, the only assumption is turbulent flow, but the reynolds number is >30,000 so I think thats a pretty safe one.

To see differences between gas and e85, change cell C8 which is the main one for the spreadsheet. The difference is very small, which is unexpected given how much guys like to say you have to upgrade your fuel lines with e85.

UPDATE 4/28/14

I added some more pumps to the spreadsheet and also did some better math so using different fuels now accounts for the density difference between e85 and gas. This is important because pumps and injectors are constant volume devices whereas the power rating is only concerned with the mass of the fuel. So it should now be more accurate for E85 estimations for pump/injector sizing and power estimation.

----------------------------------------------------------------------------------------------------

I was thinking about my track outing last weekend and was pondering over why I was so out of fuel with huge injectors, and then the realization set in that pump flow decreased much faster than injector flow increased with pressure. My suspicion was raising the base fuel pressure actually hurt me in terms of total fuel system flow.

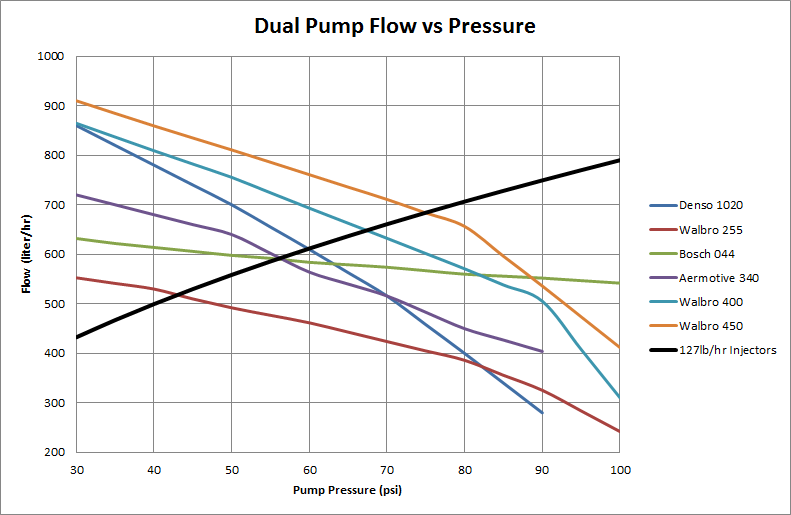

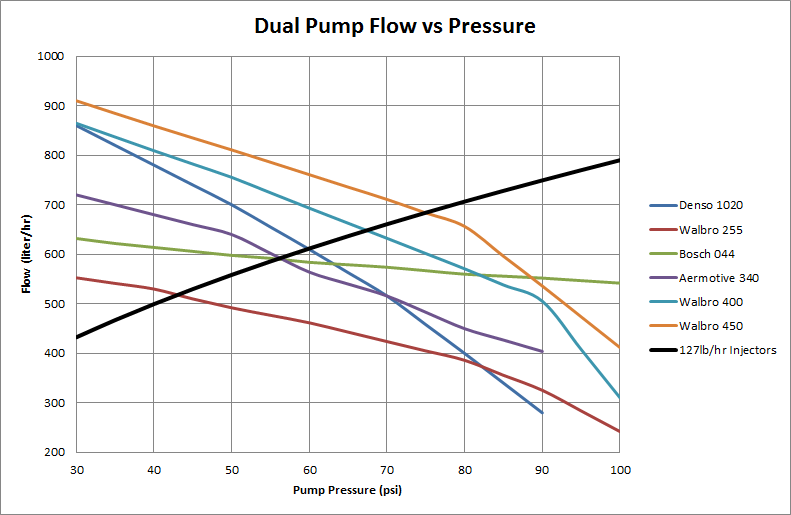

I made this spreadsheet comparing the flow rates of the most common fuel pumps in single and dual configurations; walbro 255, walbro 400, walbro 450, aeromotive 340, bosch 044, and denso 1020 (my current pumps). I found all of these flow rates on the internet and interpolated for values I didnít have to have for adequate chart resolution. I attached the spreadsheet to this post, but for the lazy ones among us I am posting a graph for discussion. I used my current 127lb/hr @4bar injectors as comparison.

To use this spreadsheet on your own setup, simply download it and change the green box to whatever your injectors are rated at 4bar. The pump flows will not change. The spreadsheet provides a nice compilation of these as well.

Assumptions

This analysis makes a few assumptions. Namely, the fuel lines, and rails are of adequate size to not cause an appreciable flow restriction (and therefor pressure drop). The voltage to the pumps is constant at 13.5v. In dual pump configurations, there is a doubling of flow. 1 US gallon=3.7854 liters, and 1lb of gasoline weighs 6.073 pounds. The injectors operate at a maximum of 95% duty cycle. Gasoline is the only fuel being used (although an e85 analysis is similar, not all pumps are e85 rated).

The thing to keep in mind is that the fuel system upper bound is determined by the least flowing component (pumps or injectors). Basically the injectors canít flow more fuel than they are given by the pumps and the pumps donít need to pump more fuel to the injectors than can be used.

Notice the black line, which is the flow rate of my injectors with respect to rail pressure. At some point it crosses all of the pump curves. It is at this intersection (to a given pump) where the injectors are using the exact amount of fuel the pumps are providing. There will be nothing returned to the tank no pressure drop at the rail at this point. To the left of this intersection there is more pump flow than injector flow, so some fuel will be returned. Similarly to the right of this point there is a lack of pump flow so rail pressure drops (which moves the pumps back to the left so they flow more).

To clarify, it is impossible to operate to the right of the intersection point since the injectors cannot flow more than the pumps. If it were on the right, the pumps would see less pressure and move to the left on their curves, where they flow more, and rebalance with the injectors. When your desired flow rate is to the right or above the intersection, the air/fuel ratio will be lean. The further away, the leaner you will be.

With larger injectors, the black line will shift upward (and obviously smaller injectors force it down). The important thing here is the intersection point. The intersection point is your maximum fuel system flow capacity. With more powerful pumps or higher voltage (boost-a-pump) the pump curves are shifted upward. The higher this intersection on the vertical axis the more power your fuel system can support.

Boost and Base Fuel Pressure

The second topic I want to talk about is boost. If you are boosted you need to be using a boost reference regulator, this will increase fuel rail pressure to compensate for boost. Notice how the pump curves decline with pressure, this is why FI needs a lot of fuel pump. With a boost referenced regulator, pressure is maintained at a constant at the fuel injector, so the injector line would be flat while the pump slopes down. It is the same conceptually, where these lines cross is your maximum fuel flow.

Reading the Graph

To use my spreadsheet, we can look at the above graph. Letís say you have dual walbro 255s and 127lb injectors and want to run a max of 20psi. The question is what is the best base pressure to use? You want this to be high enough so the injectors flow enough at idle to have good control, but low enough so you donít max out the pumps before the injectors. How you would do this is a little tricky. You want the curves of your injectors and pumps to be separated by your max boost pressure. Because injector rail pressure is held constant, it will be a flat horizontal line instead of the sloped one on the chart. So going back to my example of dual 255s, if you draw a line straight up from 58psi to the injector curve, and move 20psi to the right, where is the pump curve? It is far below the injector line, meaning our system is very pump limited. If you draw a line straight up from 35psi to the injector curve and move 20psi to the right it will hit dead even to the walbro pump curve. This means the ideal base pressure for the combination of dual walbro 255s and 127lb injectors is a 35psi base pressure. If we repeat the same process for dual walbro 400s, we find 55psi to be the ideal base pressure.

With larger injectors or smaller pumps the ideal base point is to the left, and with smaller injectors or larger pumps the ideal base point is further right. If base pressure is too high with large injectors, they will have a difficult time idling due to their minimum pulse width.

Case In Point

Lets take the case of my truck last weekend; I was running dual denso 1020s at a 70psi base and 20psi boost. If you see the chart, the means my injectors could potentially flow 650l/hr but I was pump limited to closer to 270l/hr. Which perfectly explains why adding fuel in the tune did absolutely nothing! Remember your fuel system is defined by the lower limit. If I had run a 50psi base, my injectors would only flow about 560l/hr but my pumps would flow 525l/hr. That is nearly double my total fuel system capacity at 70psi base! If I had done this analysis before last weekend I would have gotten my 9 second pass almost certainly.

Lower and Upper Limits to Boost Pressure

I talked about the upper limit in terms of becoming pump or injector limited, but the lower limit is a bit harder. As the engine speed increases, you have less time to inject enough fuel by the relation "injection time(ms)=120/RPM" in terms of miliseconds. To find a true lower limit, you would need to know your required fuel amount and at what rpm. Obviously with a higher desired rpm you want a higher base pressure. Furthermore, it becomes clear to make high-rpm, high-boost power you need massive pumps and massive injectors to support a high base pressure!

Conclusion

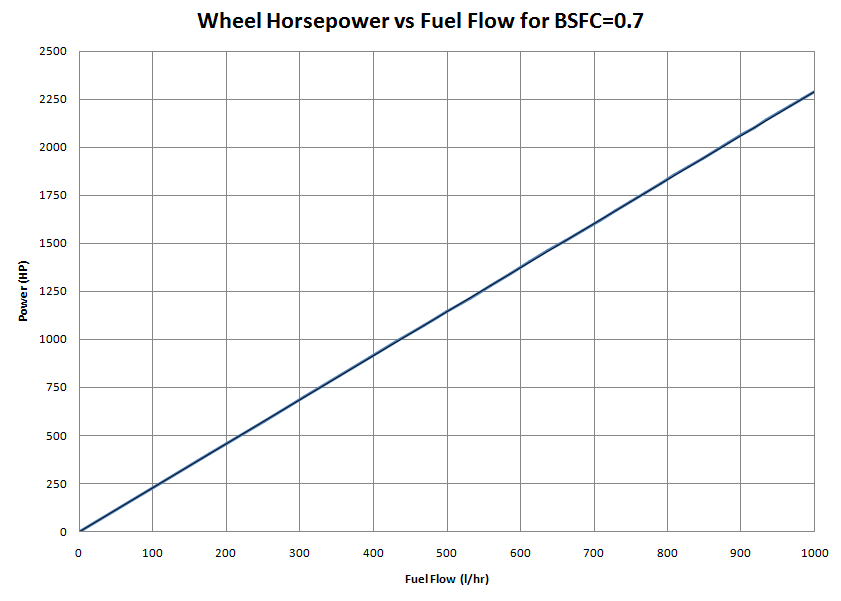

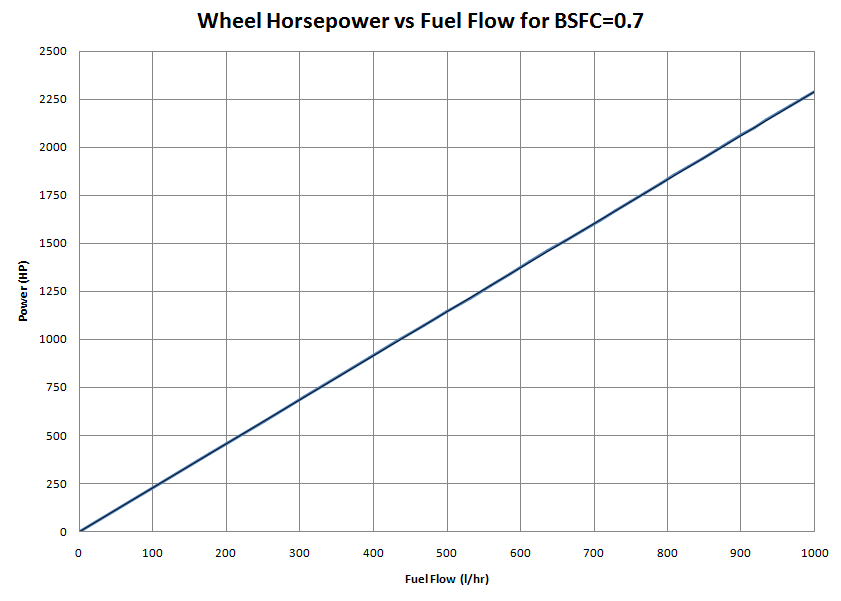

I have not seen a discussion on this before regarding pump flow and injector flow, but the analysis is surprising simple and extremely relevant. I encourage people to download the spreadsheet and play with the injector sizing to see what size injectors you will need to support the pumps you plan on going with to support the power you want to make. Fuel system flow can be related to power output by knowing your BSFC.

The main thing to take away here is running a higher base pressure does not mean you will make more power, and I was actually surprised how quickly pump flow falls off after doing this analysis.

I just made this because I cant leave things alone

I plotted fuel flow against power produced using a BFSC of 0.7, which I think is a good estimate for these trucks. How you would use this is to find at what fuel flow your pump and injectors are equalized with whatever boost you are using (that flat line you draw from the injector line to the pump line, extend it all the way to the left to find fuel system flow), and look up what power level that corresponds to on this chart:

This is wheel horse power and assuming a BSFC of 0.7. This tells you what your fuel system is capable of supporting based on what you find from the right chart in the spreadsheet.

I got an email from a guy asking about fuel line size effects so I added that part in. If you open the spreadsheet is in the top middle. Basically you look up the max volume of fuel you will flow from the tables below, or type it into one of the quick calculators on the right, to get the flow volume (L/hr). Look on the little AN table size for the different inner diameters of AN hoses. Stock 3/8" fuel line has an ID of 0.310" I believe. Also input the length of the line from the fuel pumps to the rail.

The Fitting section right below that takes into account pressure loss from the fittings you use. A union is any connection point is anywhere there is a fitting. Type in the number of different fitting types you have.

This is based on a standard fluid dynamics type calculation, the only assumption is turbulent flow, but the reynolds number is >30,000 so I think thats a pretty safe one.

To see differences between gas and e85, change cell C8 which is the main one for the spreadsheet. The difference is very small, which is unexpected given how much guys like to say you have to upgrade your fuel lines with e85.

UPDATE 4/28/14

I added some more pumps to the spreadsheet and also did some better math so using different fuels now accounts for the density difference between e85 and gas. This is important because pumps and injectors are constant volume devices whereas the power rating is only concerned with the mass of the fuel. So it should now be more accurate for E85 estimations for pump/injector sizing and power estimation.

----------------------------------------------------------------------------------------------------

I was thinking about my track outing last weekend and was pondering over why I was so out of fuel with huge injectors, and then the realization set in that pump flow decreased much faster than injector flow increased with pressure. My suspicion was raising the base fuel pressure actually hurt me in terms of total fuel system flow.

I made this spreadsheet comparing the flow rates of the most common fuel pumps in single and dual configurations; walbro 255, walbro 400, walbro 450, aeromotive 340, bosch 044, and denso 1020 (my current pumps). I found all of these flow rates on the internet and interpolated for values I didnít have to have for adequate chart resolution. I attached the spreadsheet to this post, but for the lazy ones among us I am posting a graph for discussion. I used my current 127lb/hr @4bar injectors as comparison.

To use this spreadsheet on your own setup, simply download it and change the green box to whatever your injectors are rated at 4bar. The pump flows will not change. The spreadsheet provides a nice compilation of these as well.

Assumptions

This analysis makes a few assumptions. Namely, the fuel lines, and rails are of adequate size to not cause an appreciable flow restriction (and therefor pressure drop). The voltage to the pumps is constant at 13.5v. In dual pump configurations, there is a doubling of flow. 1 US gallon=3.7854 liters, and 1lb of gasoline weighs 6.073 pounds. The injectors operate at a maximum of 95% duty cycle. Gasoline is the only fuel being used (although an e85 analysis is similar, not all pumps are e85 rated).

The thing to keep in mind is that the fuel system upper bound is determined by the least flowing component (pumps or injectors). Basically the injectors canít flow more fuel than they are given by the pumps and the pumps donít need to pump more fuel to the injectors than can be used.

Notice the black line, which is the flow rate of my injectors with respect to rail pressure. At some point it crosses all of the pump curves. It is at this intersection (to a given pump) where the injectors are using the exact amount of fuel the pumps are providing. There will be nothing returned to the tank no pressure drop at the rail at this point. To the left of this intersection there is more pump flow than injector flow, so some fuel will be returned. Similarly to the right of this point there is a lack of pump flow so rail pressure drops (which moves the pumps back to the left so they flow more).

To clarify, it is impossible to operate to the right of the intersection point since the injectors cannot flow more than the pumps. If it were on the right, the pumps would see less pressure and move to the left on their curves, where they flow more, and rebalance with the injectors. When your desired flow rate is to the right or above the intersection, the air/fuel ratio will be lean. The further away, the leaner you will be.

With larger injectors, the black line will shift upward (and obviously smaller injectors force it down). The important thing here is the intersection point. The intersection point is your maximum fuel system flow capacity. With more powerful pumps or higher voltage (boost-a-pump) the pump curves are shifted upward. The higher this intersection on the vertical axis the more power your fuel system can support.

Boost and Base Fuel Pressure

The second topic I want to talk about is boost. If you are boosted you need to be using a boost reference regulator, this will increase fuel rail pressure to compensate for boost. Notice how the pump curves decline with pressure, this is why FI needs a lot of fuel pump. With a boost referenced regulator, pressure is maintained at a constant at the fuel injector, so the injector line would be flat while the pump slopes down. It is the same conceptually, where these lines cross is your maximum fuel flow.

Reading the Graph

To use my spreadsheet, we can look at the above graph. Letís say you have dual walbro 255s and 127lb injectors and want to run a max of 20psi. The question is what is the best base pressure to use? You want this to be high enough so the injectors flow enough at idle to have good control, but low enough so you donít max out the pumps before the injectors. How you would do this is a little tricky. You want the curves of your injectors and pumps to be separated by your max boost pressure. Because injector rail pressure is held constant, it will be a flat horizontal line instead of the sloped one on the chart. So going back to my example of dual 255s, if you draw a line straight up from 58psi to the injector curve, and move 20psi to the right, where is the pump curve? It is far below the injector line, meaning our system is very pump limited. If you draw a line straight up from 35psi to the injector curve and move 20psi to the right it will hit dead even to the walbro pump curve. This means the ideal base pressure for the combination of dual walbro 255s and 127lb injectors is a 35psi base pressure. If we repeat the same process for dual walbro 400s, we find 55psi to be the ideal base pressure.

With larger injectors or smaller pumps the ideal base point is to the left, and with smaller injectors or larger pumps the ideal base point is further right. If base pressure is too high with large injectors, they will have a difficult time idling due to their minimum pulse width.

Case In Point

Lets take the case of my truck last weekend; I was running dual denso 1020s at a 70psi base and 20psi boost. If you see the chart, the means my injectors could potentially flow 650l/hr but I was pump limited to closer to 270l/hr. Which perfectly explains why adding fuel in the tune did absolutely nothing! Remember your fuel system is defined by the lower limit. If I had run a 50psi base, my injectors would only flow about 560l/hr but my pumps would flow 525l/hr. That is nearly double my total fuel system capacity at 70psi base! If I had done this analysis before last weekend I would have gotten my 9 second pass almost certainly.

Lower and Upper Limits to Boost Pressure

I talked about the upper limit in terms of becoming pump or injector limited, but the lower limit is a bit harder. As the engine speed increases, you have less time to inject enough fuel by the relation "injection time(ms)=120/RPM" in terms of miliseconds. To find a true lower limit, you would need to know your required fuel amount and at what rpm. Obviously with a higher desired rpm you want a higher base pressure. Furthermore, it becomes clear to make high-rpm, high-boost power you need massive pumps and massive injectors to support a high base pressure!

Conclusion

I have not seen a discussion on this before regarding pump flow and injector flow, but the analysis is surprising simple and extremely relevant. I encourage people to download the spreadsheet and play with the injector sizing to see what size injectors you will need to support the pumps you plan on going with to support the power you want to make. Fuel system flow can be related to power output by knowing your BSFC.

The main thing to take away here is running a higher base pressure does not mean you will make more power, and I was actually surprised how quickly pump flow falls off after doing this analysis.

I just made this because I cant leave things alone

I plotted fuel flow against power produced using a BFSC of 0.7, which I think is a good estimate for these trucks. How you would use this is to find at what fuel flow your pump and injectors are equalized with whatever boost you are using (that flat line you draw from the injector line to the pump line, extend it all the way to the left to find fuel system flow), and look up what power level that corresponds to on this chart:

This is wheel horse power and assuming a BSFC of 0.7. This tells you what your fuel system is capable of supporting based on what you find from the right chart in the spreadsheet.

Last edited by Atomic; 02-09-2015 at 04:35 PM.

#7

Thread Starter

I have a gauge for that

iTrader: (42)

Joined: Jan 2006

Posts: 16,266

Likes: 394

From: Huntsville, AL

Pretty much. Injector flow increases with pressure, and pump flow decreases with pressure. The key thing here is pump flow decreases much faster than injector flow increases with additional pressure.

Trending Topics

#9

Good writeup

#10

Thread Starter

I have a gauge for that

iTrader: (42)

Joined: Jan 2006

Posts: 16,266

Likes: 394

From: Huntsville, AL

There are a lot of things that can be expanded upon. For instance, I dont mention at lower pressures if the pulse width will be sufficient for a given size injector at high rpm. You need to know what RPM you plan to shift at, as well as injector size, fuel pump flow, fuel composition, and even camshaft duration. This is simply intended to find the optimum base pressure point point in regards to fuel pump flow vs injector flow. Basically ensuring you have the maximum amount of fuel available at full boost.