high oil preesure + turbo

#12

11 Second Club

Thread Starter

iTrader: (1)

Join Date: Nov 2006

Posts: 742

Likes: 0

Received 0 Likes

on

0 Posts

I do have a -8 drain line, and I just got off of the prone with Rick, and that's what we were talking about. My question is, how do you get the -10 line out of the turbo, because my -8 line just fits.

Oh yea, and it smokes a lot worse when it's cold. Should I also switch to 0-30 oil?

Oh yea, and it smokes a lot worse when it's cold. Should I also switch to 0-30 oil?

#13

Teching In

Join Date: Nov 2007

Location: San Diego, CA

Posts: 19

Likes: 0

Received 0 Likes

on

0 Posts

I do have a -8 drain line, and I just got off of the prone with Rick, and that's what we were talking about. My question is, how do you get the -10 line out of the turbo, because my -8 line just fits.

Oh yea, and it smokes a lot worse when it's cold. Should I also switch to 0-30 oil?

Oh yea, and it smokes a lot worse when it's cold. Should I also switch to 0-30 oil?

Good luck! :nunchuk1:

#16

11 Second Club

Thread Starter

iTrader: (1)

Join Date: Nov 2006

Posts: 742

Likes: 0

Received 0 Likes

on

0 Posts

The parts to make my oil drain -10 will be here soon. I am having a hard time believing it will fix my problem, but I will do it. The inside of the fittings are 100ths of an inch bigger on the inside, and like gadget said my feed line is tiny in comparison, and I have a .025 restrictor in it.

We will see next week.

We will see next week.

#18

Teching In

Join Date: Nov 2007

Location: San Diego, CA

Posts: 19

Likes: 0

Received 0 Likes

on

0 Posts

The parts to make my oil drain -10 will be here soon. I am having a hard time believing it will fix my problem, but I will do it. The inside of the fittings are 100ths of an inch bigger on the inside, and like gadget said my feed line is tiny in comparison, and I have a .025 restrictor in it.

We will see next week.

We will see next week.

Secondly you have to remember the more you restrict the oil supply line in "comparison" to your main oil pressure. It is adding more velocity with less flow! Something to ponder over?

Glad I could help!

#19

I have dealt with this issue. The things that you will need are -10 return (no if, and's, or but's), Make sure you don't have a angled fitting coming off for your return (Nelson racing engines makes a nice straight pipe to -10 fitting), and check your PCV system for proper operation. These small checks will save you the headache. PCV is crucial along with your return line being straight and big enough. Especially with that amount of oil pressure. Oil when it hits that turbo at high temps. and velocity becomes frothy. This causes pockets in the Turbo oil return line which can back up that flow!

Good luck! :nunchuk1:

Good luck! :nunchuk1:

#20

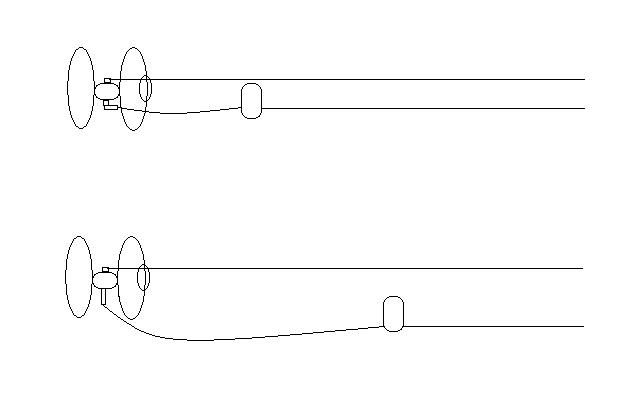

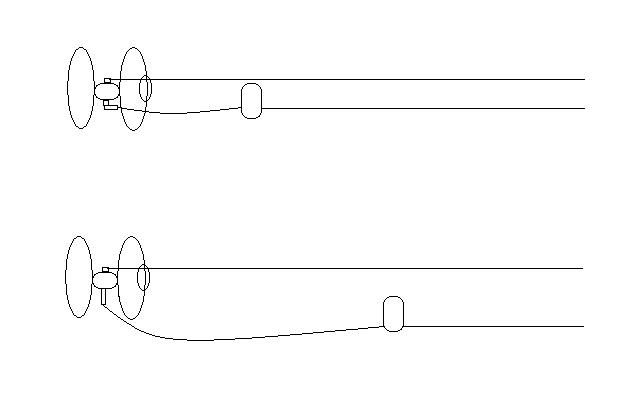

Here is a quick diagram I did to illustrate what I want to do. So on top of running bigger(-10) lines I want to use a pipe that goes straight down instead of the 90* bend and move the oil pump so I can have more line between it and the turbo.

I know it looks like an Etch-a-Sketch, lol.

I know it looks like an Etch-a-Sketch, lol.