Mismatched combo. Undersized turbo. Where to go next.

#22

. I have this tendancy to over think things. Especially, when I've never done it before. Heck, ive never even ridden in a turbo ls. This is my first rodeo. Maybe I should just get the fuel system lined out, tune it, and

. I have this tendancy to over think things. Especially, when I've never done it before. Heck, ive never even ridden in a turbo ls. This is my first rodeo. Maybe I should just get the fuel system lined out, tune it, and  Then go from there.

Then go from there.

#23

I have a gauge for that

iTrader: (42)

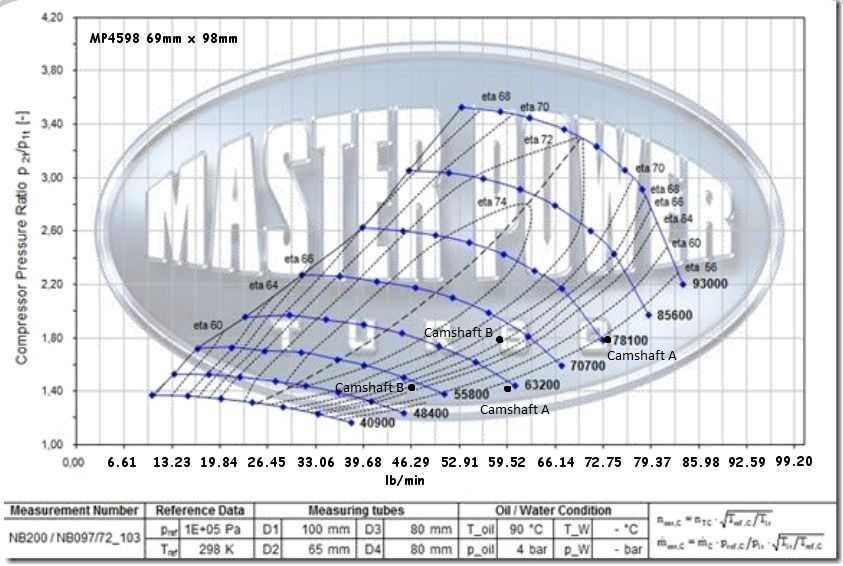

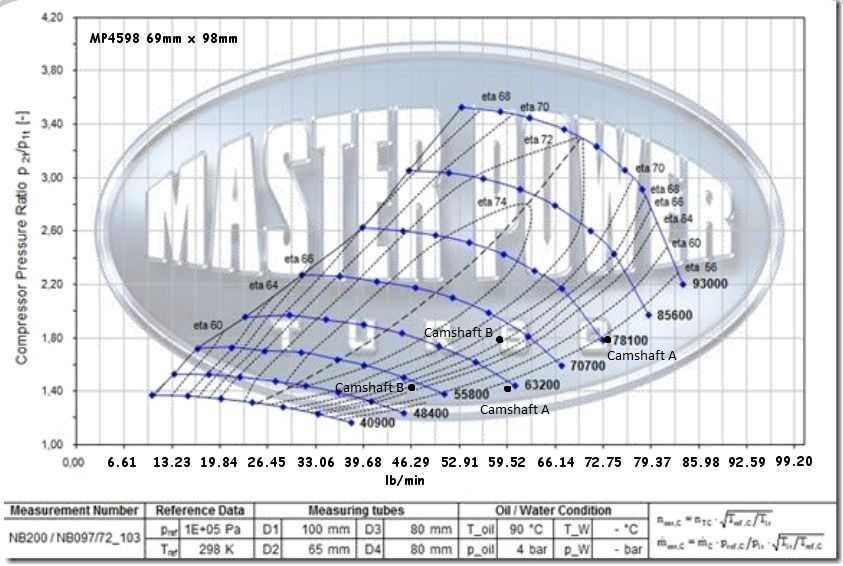

Made an attempt at plotting my setup on a compressor map

Camshaft A (current cam):

Calculated at 6500rpms and 85% volumetric efficiency. Converted to lbs/min by multiplying by .0691, which should relate to 120 degrees F.

Camshaft B (stock cam):

Calculated at 5800rpms and 75% volumetric efficiency. Converted the same way as above.

I graphed at a 1.48 pressure ratio (7psi) and a 1.82 pressure ratio (12psi). First attempt at getting data from a compressor map, so feel free to check my math. Looks like the stock cam/lower shift points fall into the compressor efficiency much better. Dont really know what else to make of the data though.

Camshaft A (current cam):

Calculated at 6500rpms and 85% volumetric efficiency. Converted to lbs/min by multiplying by .0691, which should relate to 120 degrees F.

Camshaft B (stock cam):

Calculated at 5800rpms and 75% volumetric efficiency. Converted the same way as above.

I graphed at a 1.48 pressure ratio (7psi) and a 1.82 pressure ratio (12psi). First attempt at getting data from a compressor map, so feel free to check my math. Looks like the stock cam/lower shift points fall into the compressor efficiency much better. Dont really know what else to make of the data though.

3500rpm: 32.1 lb/min

6500rpm: 59.7 lb/min

I would probably want to run around 15psi (pr=~2)

3500rpm: 35.2 lb/min

6500rpm: 65.4 lb/min

And shift it around 6000rpm, which is about 60 lb/min.

I plotted what the turbo would be doing on the attached image. As you can see, its actually better to run more boost and shift sooner than a lower boost and shift later. With the higher boost, you will spend a greater portion of the time in the most efficient part of the compressor map.

#24

I think you cam VE might be a little optimistic, I would think around 80%. I ran some numbers and at 12psi (pr=1.81):

3500rpm: 32.1 lb/min

6500rpm: 59.7 lb/min

I would probably want to run around 15psi (pr=~2)

3500rpm: 35.2 lb/min

6500rpm: 65.4 lb/min

And shift it around 6000rpm, which is about 60 lb/min.

I plotted what the turbo would be doing on the attached image. As you can see, its actually better to run more boost and shift sooner than a lower boost and shift later. With the higher boost, you will spend a greater portion of the time in the most efficient part of the compressor map.

3500rpm: 32.1 lb/min

6500rpm: 59.7 lb/min

I would probably want to run around 15psi (pr=~2)

3500rpm: 35.2 lb/min

6500rpm: 65.4 lb/min

And shift it around 6000rpm, which is about 60 lb/min.

I plotted what the turbo would be doing on the attached image. As you can see, its actually better to run more boost and shift sooner than a lower boost and shift later. With the higher boost, you will spend a greater portion of the time in the most efficient part of the compressor map.

You are my hero atomic. That picture you attached, put things into much better perspective for me. I see how you plotted the graph through a RANGE of rpms. This makes much more sense to read the compressor map through a range of rpms, then just a few plots. I get now what you mean by moving horizontally aross the map as rpms increase.

You are my hero atomic. That picture you attached, put things into much better perspective for me. I see how you plotted the graph through a RANGE of rpms. This makes much more sense to read the compressor map through a range of rpms, then just a few plots. I get now what you mean by moving horizontally aross the map as rpms increase.It also makes sense how at a higher pressure ratio, I can stay in the most efficient part of the compressor map. I guess i just needed it plotted out in a RANGE of rpms to understand that better. Thanks for the help

#25

I have a gauge for that

iTrader: (42)

No problem :thumbup:

Its important to keep in mind this works for that map you posted...all turbos of the same size do NOT have the same compressor maps, or even close possibly. A quick rule of thumb is 1 lb/min of air will support 10rwhp, so 60lb/min is about 600rwhp which is close to the 650 number someone said before these turbos typically tap out at.

The hard part of turbo selection is really taken away from the consumer, and that is compressor-turbine matching. You see some really weird stuff when someone gets the bright idea to put say a 100mm compressor on a 80mm turbine. Turbo just sucks. Or the other way like Kyle said, but in that case is only bad for responsiveness and would actually be a very good race setup in a size limited class, but I digress.

Its important to keep in mind this works for that map you posted...all turbos of the same size do NOT have the same compressor maps, or even close possibly. A quick rule of thumb is 1 lb/min of air will support 10rwhp, so 60lb/min is about 600rwhp which is close to the 650 number someone said before these turbos typically tap out at.

The hard part of turbo selection is really taken away from the consumer, and that is compressor-turbine matching. You see some really weird stuff when someone gets the bright idea to put say a 100mm compressor on a 80mm turbine. Turbo just sucks. Or the other way like Kyle said, but in that case is only bad for responsiveness and would actually be a very good race setup in a size limited class, but I digress.

#26

No problem :thumbup:

Its important to keep in mind this works for that map you posted...all turbos of the same size do NOT have the same compressor maps, or even close possibly. A quick rule of thumb is 1 lb/min of air will support 10rwhp, so 60lb/min is about 600rwhp which is close to the 650 number someone said before these turbos typically tap out at.

The hard part of turbo selection is really taken away from the consumer, and that is compressor-turbine matching. You see some really weird stuff when someone gets the bright idea to put say a 100mm compressor on a 80mm turbine. Turbo just sucks. Or the other way like Kyle said, but in that case is only bad for responsiveness and would actually be a very good race setup in a size limited class, but I digress.

Its important to keep in mind this works for that map you posted...all turbos of the same size do NOT have the same compressor maps, or even close possibly. A quick rule of thumb is 1 lb/min of air will support 10rwhp, so 60lb/min is about 600rwhp which is close to the 650 number someone said before these turbos typically tap out at.

The hard part of turbo selection is really taken away from the consumer, and that is compressor-turbine matching. You see some really weird stuff when someone gets the bright idea to put say a 100mm compressor on a 80mm turbine. Turbo just sucks. Or the other way like Kyle said, but in that case is only bad for responsiveness and would actually be a very good race setup in a size limited class, but I digress.

100mm compressor on an 80mm turbine

Sounds like an on3. 76mm compressor on a 65mm turbine. Is there any benefit of having a small turbine on a big compressor? Kyles example sounds similar to my turbo.

Sounds like an on3. 76mm compressor on a 65mm turbine. Is there any benefit of having a small turbine on a big compressor? Kyles example sounds similar to my turbo.

#27

I have a gauge for that

iTrader: (42)

Eh, maybe if you want a high pressure ratio on a small displacement engine, like an import or something. But big engines need big turbines. The turbine wheel is the most expensive part of the turbo, and also the biggest factor when dealing with lag. Small turbine = cheaper = faster spool, but will also give a high backpressure pretty quickly with a lot of rpm....so you may find that combo on a diesel actually.

#28

TECH Fanatic

iTrader: (2)

Join Date: Oct 2006

Location: slidell, LA

Posts: 1,118

Likes: 0

Received 0 Likes

on

0 Posts

Diesels generally use big turbines and smaller compressors. Mainly Bc they need to flow a lot of exhaust and spool fast with high pressure ratios. I had an on3 76/64 on my setup and boost threshold was Damn near instant but it chocked past 5500 so I had I shifting at 5800. It ran 10.97 @125 on 14psi but it was pretty much done. No I have a cxracing 80/77 and it's a totally different monster. Boost threshold is a little higher but when it gets spooled it keeps pulling hard up top. Did the compressor size increase help? I'm sure it did but I feel the biggest reason for the power increase is the bigger turbine

#29

Figured I would do a little follow up. Got the whole fuel system done and upgraded to a 3 bar os. I currently feel the truck is a little lacking. I've only got the 4 pound spring in the gate. Map shows it boosting 4psi-6.2psi. Boost gauges bounces around 6psi or a hair higher.

I feel like I've got a few things setup very mild, and am wanting peoples opinion on where to "lean" on it first. Setup as follows:

Boost- 4psi. Reads 4psi-6.2psi

Timing - commanding around 16. Getting 12ish. Aggressive iat retard table. Will post below.

Shift points - 5500

Afr - commanding 10.8. Runs 10.6 - 10.8. Using boost enrichment. 12.5 AFR commanded for power enrichment.

Just wanting to know where everyone would go next. Ease out the timing, raise the boost, raise shifts, etc... This is my first turbo setup, and want to do it right. Here's a few pics of the logs and tune:

I feel like I've got a few things setup very mild, and am wanting peoples opinion on where to "lean" on it first. Setup as follows:

Boost- 4psi. Reads 4psi-6.2psi

Timing - commanding around 16. Getting 12ish. Aggressive iat retard table. Will post below.

Shift points - 5500

Afr - commanding 10.8. Runs 10.6 - 10.8. Using boost enrichment. 12.5 AFR commanded for power enrichment.

Just wanting to know where everyone would go next. Ease out the timing, raise the boost, raise shifts, etc... This is my first turbo setup, and want to do it right. Here's a few pics of the logs and tune: