Physical Range of 90mm LS2 vs 78mm TB

#31

I don't think that the PCM is processing the actual sensor outputs otherwise my 04 PCM would be upset about the TP sensors moving in opposite directions. Seems like what it is looking at is the 0 - 39.2% value for each sensor from the TAC module as this looks identical in all setups. So I'm not optomistic about a software solution.

Played around a lot with the wiring and internal circuitry on the 90mm and even though I could get sensor outputs that looked like a stock 78mm in some cases(even .5 - 4.2V ranges moving in the same direction), there were still unseen issues with S1/S2 correlation at key on that triggered REP mode. It was interesting that some configurations caused me to reach the 39.2% value at even less than 3.9V although the sensor ranges looked normal. Could have something to do with being in REP mode though.

LS2 TAC is part of the PCM. It's not a separate module. Some other TBs like the SSR's, may function normally(open to 92%) with an 02 TAC module if their sensor range is more similar to the 02 78mm. Might explain why they also have this issue when they switch to the 'vette 90mm.

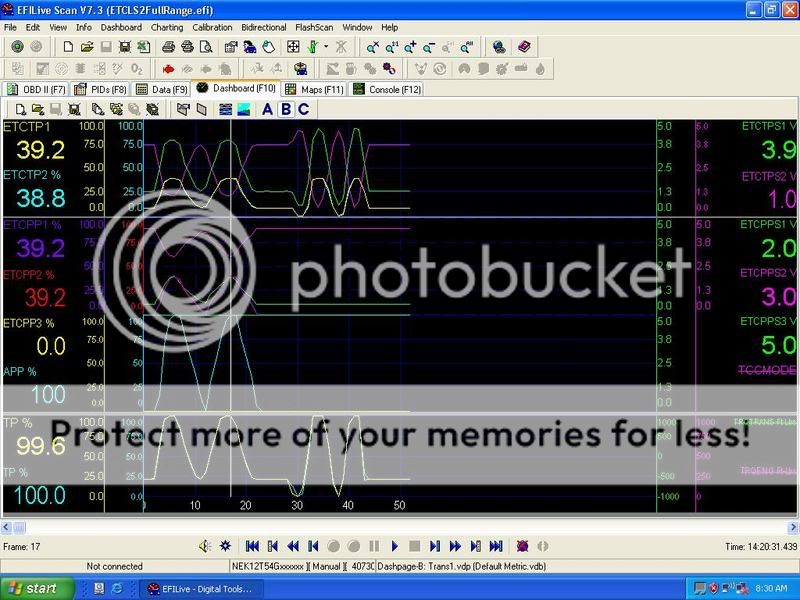

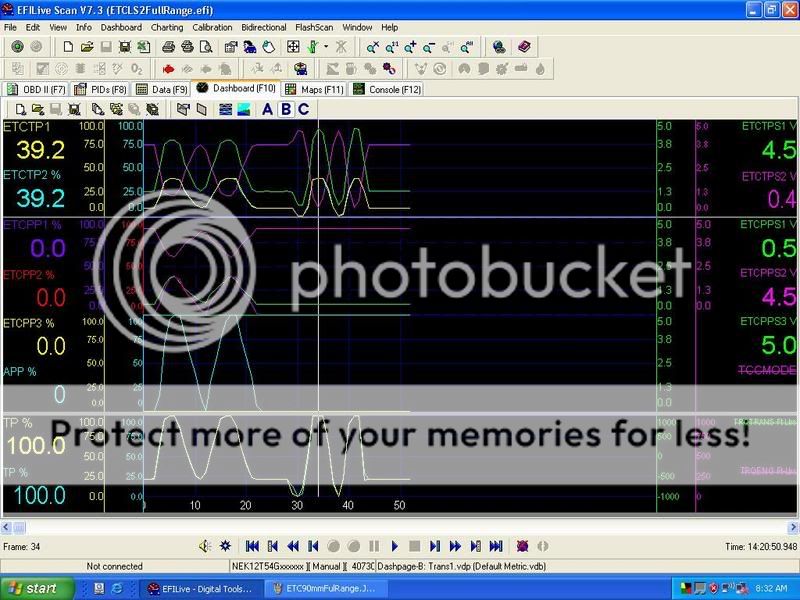

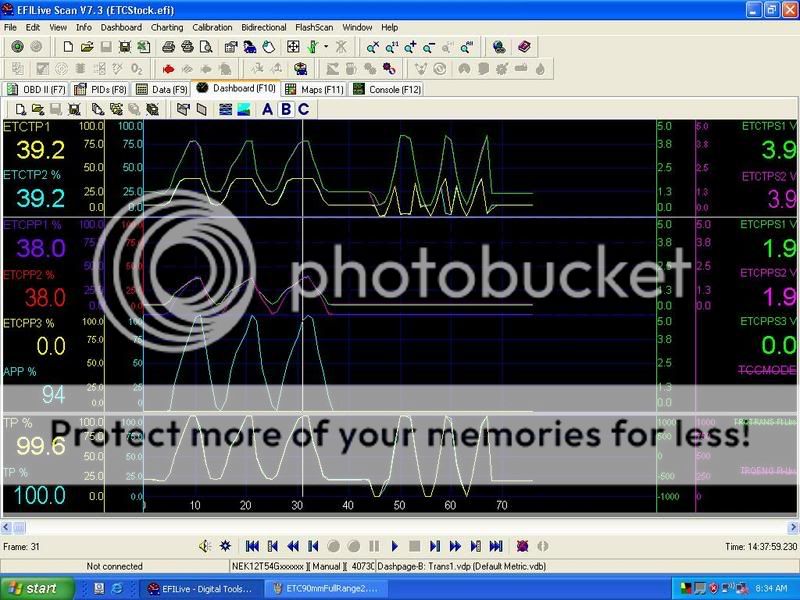

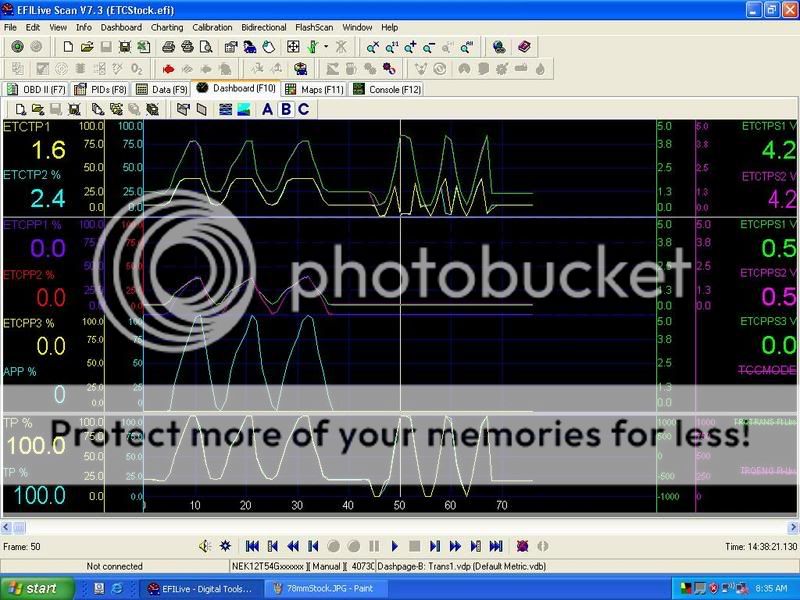

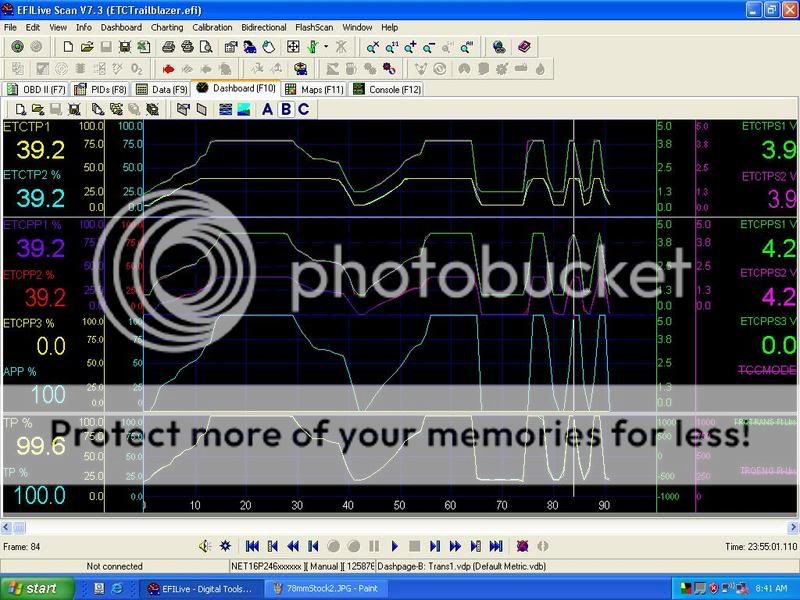

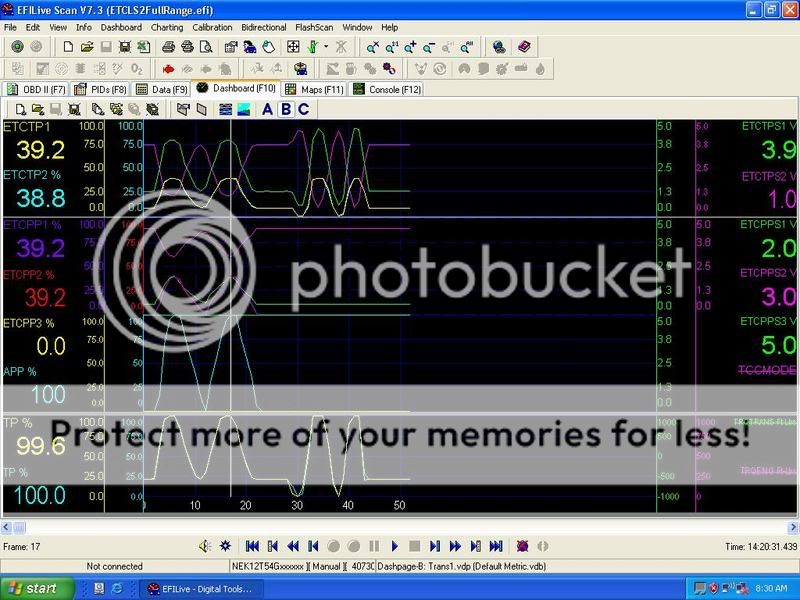

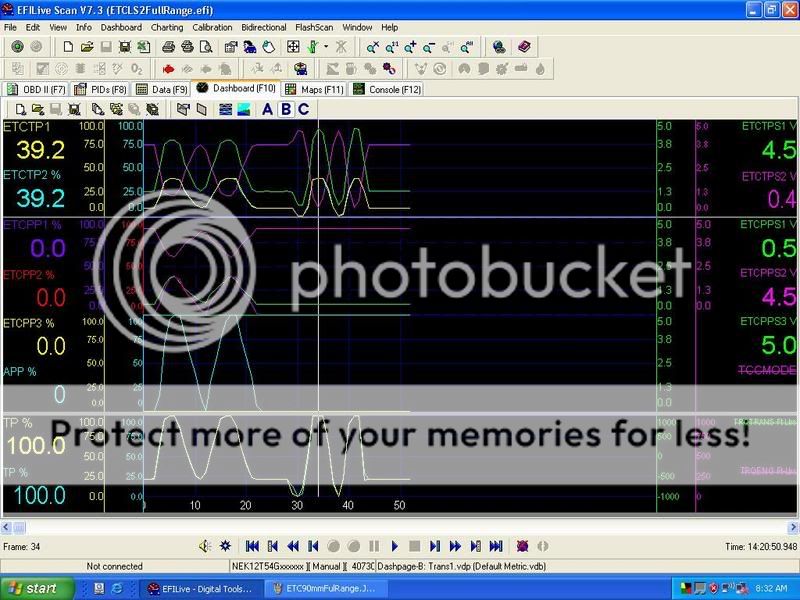

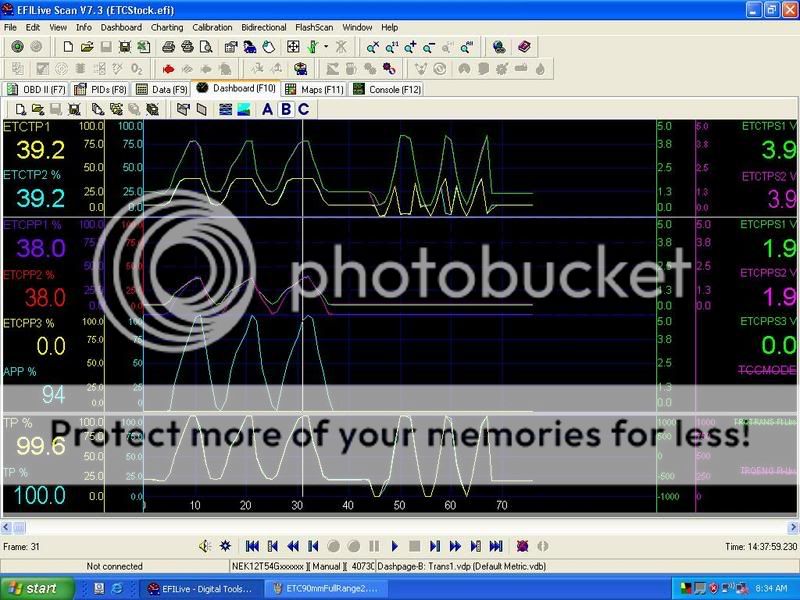

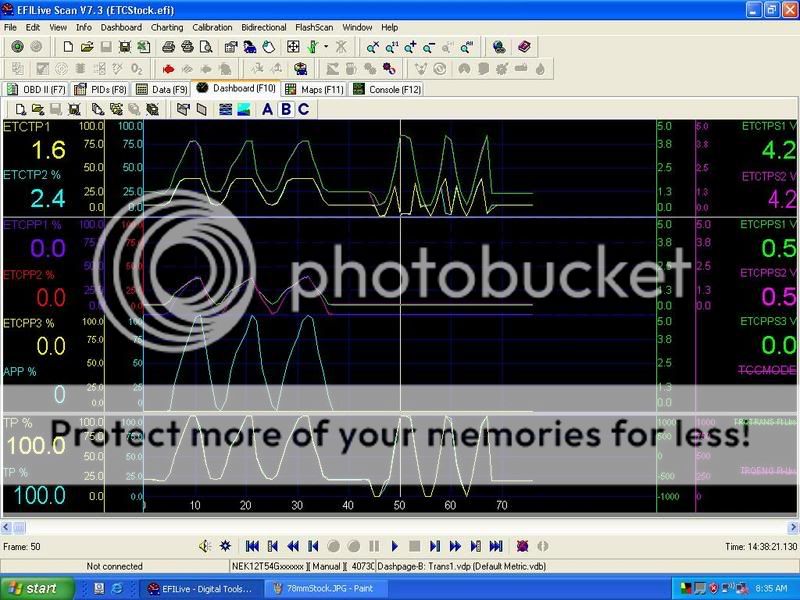

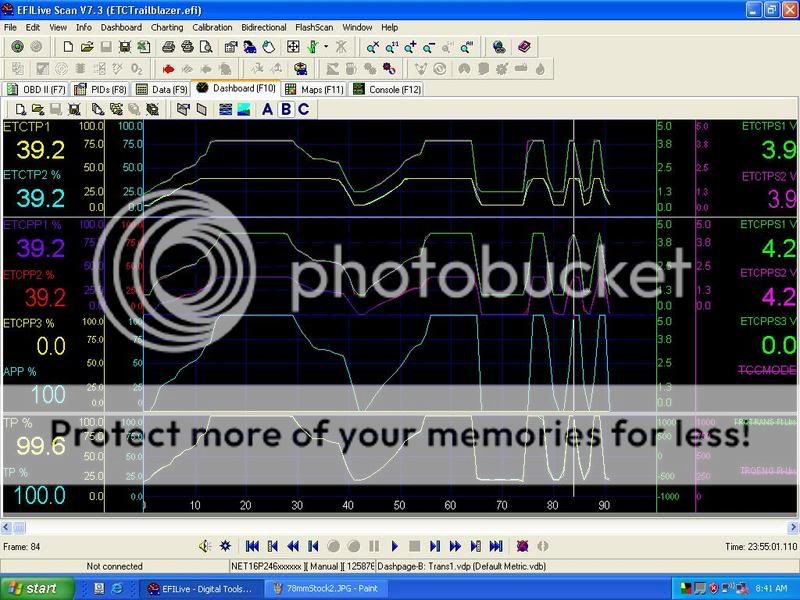

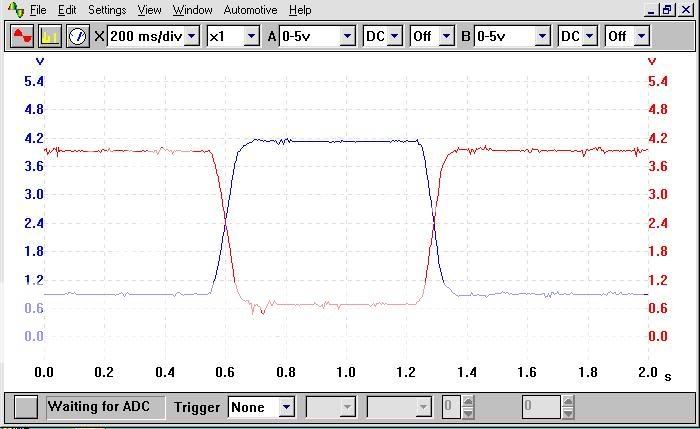

Here's a few screenshots from my logs. First 2 are the LS2 TB, next 2 the stock 78mm/04 TAC module combo, and finally a completely stock 5.3 on a 2004 Trailblazer. Fist part of the log is the TB operated via the pedal. Second part is manual movement of the blade stop to stop. Didn't do the manual for the Trailblazer. But you can see that 3.9V seems to be the magic number(1.0V where there is a descending sensor).

Just noticed that the TP% did not wrap with the 02 TAC module(2nd pic). Although it still did not go beyond 39.2%.

Played around a lot with the wiring and internal circuitry on the 90mm and even though I could get sensor outputs that looked like a stock 78mm in some cases(even .5 - 4.2V ranges moving in the same direction), there were still unseen issues with S1/S2 correlation at key on that triggered REP mode. It was interesting that some configurations caused me to reach the 39.2% value at even less than 3.9V although the sensor ranges looked normal. Could have something to do with being in REP mode though.

LS2 TAC is part of the PCM. It's not a separate module. Some other TBs like the SSR's, may function normally(open to 92%) with an 02 TAC module if their sensor range is more similar to the 02 78mm. Might explain why they also have this issue when they switch to the 'vette 90mm.

Here's a few screenshots from my logs. First 2 are the LS2 TB, next 2 the stock 78mm/04 TAC module combo, and finally a completely stock 5.3 on a 2004 Trailblazer. Fist part of the log is the TB operated via the pedal. Second part is manual movement of the blade stop to stop. Didn't do the manual for the Trailblazer. But you can see that 3.9V seems to be the magic number(1.0V where there is a descending sensor).

Just noticed that the TP% did not wrap with the 02 TAC module(2nd pic). Although it still did not go beyond 39.2%.

Last edited by DrX; 11-18-2006 at 09:18 AM.

#33

TECH Veteran

iTrader: (2)

Am I missing something here? It looks like the 78mm TB is open all the way-100% and the 90mm TB is opened past 100%.

Is this a good thing or am I not seeing something? I'm thinking that being able to open past straight (90*) is the same as not opening up to even the 90* point. Either way it creates a restriction in flow.

78MM

90MM

[/QUOTE]

[/QUOTE]

Is this a good thing or am I not seeing something? I'm thinking that being able to open past straight (90*) is the same as not opening up to even the 90* point. Either way it creates a restriction in flow.

78MM

90MM

[/QUOTE]

[/QUOTE]

#37

FormerVendor

iTrader: (3)

Join Date: May 2002

Location: Reseda, CA

Posts: 1,853

Likes: 0

Received 0 Likes

on

0 Posts

Interesting info DrX. So it's looking like the fix for this might have to be some type of converter box to modulate voltages in both directions? Am I reading this right?

Grippy: I bet the pcm would flip out trying to control TM without being able to control the ttb. Idle control would also be a problem becasue the cable trucks have a IAC system and the DWB's don't.

Richard

Grippy: I bet the pcm would flip out trying to control TM without being able to control the ttb. Idle control would also be a problem becasue the cable trucks have a IAC system and the DWB's don't.

Richard

#39

Originally Posted by Richard@WCCH

Interesting info DrX. So it's looking like the fix for this might have to be some type of converter box to modulate voltages in both directions? Am I reading this right?

Grippy: I bet the pcm would flip out trying to control TM without being able to control the ttb. Idle control would also be a problem becasue the cable trucks have a IAC system and the DWB's don't.

Richard

Grippy: I bet the pcm would flip out trying to control TM without being able to control the ttb. Idle control would also be a problem becasue the cable trucks have a IAC system and the DWB's don't.

Richard

Looks like the IAC stuff is still active at least in my 04 tune and PCM. Might be able to disable the ETC DTCs in the tune. So a cable setup may work. Seems like a lot of work though. I thought someone did this already.

Last edited by DrX; 11-18-2006 at 12:33 PM.

#40

? ? ? ? ? ?

iTrader: (16)

I was just reading over some of the GM service manuals for various electric driven TB vehicles. Although it didn't come outright and say this, one statement I read made me think the PCM only watches sensor 1 for the TB and the pedal. The TAC on the other hand monitors the relationship between the sensor 1 and sensor 2 and reports back to the PCM that everything is in proper order. Out stock TB and the LS2 stuff have sensor 1 going in the same direction, which is why the PCM works with the LS2 parts. The TAC on the other hand is concerned about sensor 2, which is why it needs to be swapped out with the LS2 parts.

The C5 vettes work off the same voltage ranges as the 02 trucks, which should put them in a similar situation as us with 3.9v being full throttle (85% open blade). Is 100% confirmed that the LS2 TB opens 100% on the C5 vettes?

The C5 vettes work off the same voltage ranges as the 02 trucks, which should put them in a similar situation as us with 3.9v being full throttle (85% open blade). Is 100% confirmed that the LS2 TB opens 100% on the C5 vettes?