Questions on PCV removal, and boost reference source.

#12

This set-up is just not working out.

I think the lines are too small to vent off all the crank pressure. Twice it has popped the lid off the first catch can and broken the JB weld sealing the first fitting to the can. This is at little to no boost too!

Maybe I have other issues?!

I tried fitting my one way valve PCV into the last return line to keep boost from entering the catch can system backwards, but think its flow is affecting the amount of volume being able to flow through the cans.

Is there a bigger one way PCV out there??

What the hell can I use to properly vent this engine without reburning all the oil and crud??

Should I just plumb it into the intake like sparkwirez06 stated above?? seems like a bad idea to me, at least for a street driven truck.

Maybe a large oil/water seperator used in air compressor systems?

If anyone has any insight or idea of what could be happening please post up for me. I'm at my witts end with this stupid ****.

I really don't understand how I coud be getting anypressure signifigant enough to blow the lid off a can and crack JB weld at 1psi of boost?!?!?

Looks like I need a leakdown tester.

I think the lines are too small to vent off all the crank pressure. Twice it has popped the lid off the first catch can and broken the JB weld sealing the first fitting to the can. This is at little to no boost too!

Maybe I have other issues?!

I tried fitting my one way valve PCV into the last return line to keep boost from entering the catch can system backwards, but think its flow is affecting the amount of volume being able to flow through the cans.

Is there a bigger one way PCV out there??

What the hell can I use to properly vent this engine without reburning all the oil and crud??

Should I just plumb it into the intake like sparkwirez06 stated above?? seems like a bad idea to me, at least for a street driven truck.

Maybe a large oil/water seperator used in air compressor systems?

If anyone has any insight or idea of what could be happening please post up for me. I'm at my witts end with this stupid ****.

I really don't understand how I coud be getting anypressure signifigant enough to blow the lid off a can and crack JB weld at 1psi of boost?!?!?

Looks like I need a leakdown tester.

Last edited by TG02Z71; 05-30-2006 at 06:11 PM.

#13

I must be the only guy to ever have oil puking issues. Looks like I'm going to have to get STS involved somehow. I was hoping that they would posibly see the post since they are sponsors now. Time to call Mr. South I guess.

The thing that really driving me nuts is I can't go to the strip with it doing this ****! Unless I want to get black flagged or kicked out that is.

I have off work for three more days and was hoping to go before the weekend.

The thing that really driving me nuts is I can't go to the strip with it doing this ****! Unless I want to get black flagged or kicked out that is.

I have off work for three more days and was hoping to go before the weekend.

#14

Did a little test this morning, I cut the line going into the series of catch cans and put my air compressor line into it at various psi levels using the regulator.

Tried 10, then 20, then 40, and finally 50psi. None of these settings made the can top pop off!! i did'nt want to go higher and crack the JB weld again, i just re-did that last night.

So how much pressure is the engine putting out??? Do I have some pistons problems or what?

Does anyone kow how much PSI the crankcase could produce under extreme circumstances or when you have a cracked piston bleeding prssure into the crankcase?

Thanks guys.

Tried 10, then 20, then 40, and finally 50psi. None of these settings made the can top pop off!! i did'nt want to go higher and crack the JB weld again, i just re-did that last night.

So how much pressure is the engine putting out??? Do I have some pistons problems or what?

Does anyone kow how much PSI the crankcase could produce under extreme circumstances or when you have a cracked piston bleeding prssure into the crankcase?

Thanks guys.

#15

Well the saga continues.

I re-did the JB weld one more time last night. Installed two pcv valves one on each line before the tee that connects them. I also installed a big one way valve I got at NAPA after the cans so boost could not back up into the cans.

Everting seemed good until I got into the boost at about 4psi...POP the lid popped off the first and last can again!!

I will take pics of the current configuration for better desriptions.

Still think its just the restriction causing this issue. I need bigger fittings or a bigger can set-up, or both.

One thing I did not realize is that PCV valves must be installed vertically or they will not work properly, mine are now orientated correctly, but still did not help.

I've cut enough rubber hose to plumb a whole damm sprikler system!!

Back to the drawing board I guess.

I re-did the JB weld one more time last night. Installed two pcv valves one on each line before the tee that connects them. I also installed a big one way valve I got at NAPA after the cans so boost could not back up into the cans.

Everting seemed good until I got into the boost at about 4psi...POP the lid popped off the first and last can again!!

I will take pics of the current configuration for better desriptions.

Still think its just the restriction causing this issue. I need bigger fittings or a bigger can set-up, or both.

One thing I did not realize is that PCV valves must be installed vertically or they will not work properly, mine are now orientated correctly, but still did not help.

I've cut enough rubber hose to plumb a whole damm sprikler system!!

Back to the drawing board I guess.

#16

The hob switch and the electric vent valve go in line between the tb and passenger side valve cover. When the hob switch detects pressure it sends 12 volts to the vent valve which keeps boost pressure from entering the crankcase. By the way you have to ground the valve mounting bracket so you will have a complete circuit. Then you need to pull out your pcv valve and see if it works like a check valve. Some chevy trucks pcv valves do not work like check valves they are a calibrated oriface. If you have the new style valve it will allow boost in you crankcase. You need one that rattles when you shake it. My truck has 119,000 miles is running 15psi and blows no oil in fact it uses no oil between 3000 mile oil changes. If you dont have all the sts parts you could use a one wire fuel tank switching valve from a 70s chevy truck. Make it where the crankcase vents to the tb with no boost and to a crankcase filter when under boost. Check you're compression if this doen't work.

Last edited by Dirty Dave; 05-31-2006 at 10:46 PM.

#17

Thanks DirtyDave.

I have no solenoid hooked up at the moment and have had a check valve type PCV for a while now. I actually have two now.

Check the set-up pics I just took.

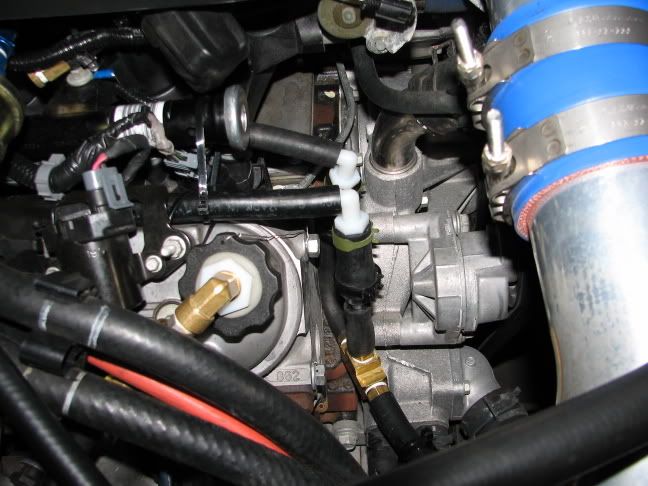

1st pic is of the two PCV valves after the lines coming from both valve covers. They are inside that short rubber hose with the 90 degree nylon fittings above them.

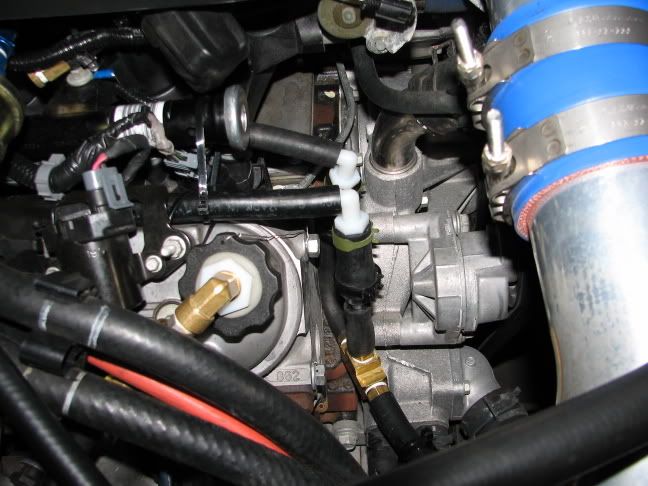

2nd pic is of the catch cans and the new one way valve I installed today to keep boost from backing up into the cans from the intake maifold where it vents to. This may be an issue since when under boost the system may not allow venting to the original PCV manifold nipple.

3rd pic is of the overall set up for reference.

I have no solenoid hooked up at the moment and have had a check valve type PCV for a while now. I actually have two now.

Check the set-up pics I just took.

1st pic is of the two PCV valves after the lines coming from both valve covers. They are inside that short rubber hose with the 90 degree nylon fittings above them.

2nd pic is of the catch cans and the new one way valve I installed today to keep boost from backing up into the cans from the intake maifold where it vents to. This may be an issue since when under boost the system may not allow venting to the original PCV manifold nipple.

3rd pic is of the overall set up for reference.

Thread

Thread Starter

Forum

Replies

Last Post