warping wires/wire tuck

#1

On The Tree

Thread Starter

iTrader: (1)

Join Date: Jan 2012

Posts: 137

Likes: 0

Received 0 Likes

on

0 Posts

Should I wrap my wires or do a wire tuck? If i do a wire tuck i would have to cut and lengthen a lot of the wires (almost all) lol. Any down sides to doing a whole wire tuck like that? Anyone do one before?

If i wrap the wires they will still be really close to the hot side of my turbo. how would they hold up like that?

Thanks

Here is my build thread for more info.

https://www.performancetrucks.net/fo...-build-510701/

If i wrap the wires they will still be really close to the hot side of my turbo. how would they hold up like that?

Thanks

Here is my build thread for more info.

https://www.performancetrucks.net/fo...-build-510701/

#6

U know what I did I took the Taylor wraps the frist time and it still melted so I said ok let's try ten foil and and wrapped the whole hot side then put the wraps over it never had a problem what so ever good luck I got tired of paying 70 dollars for them damn msd wires

Trending Topics

#8

Staging Lane

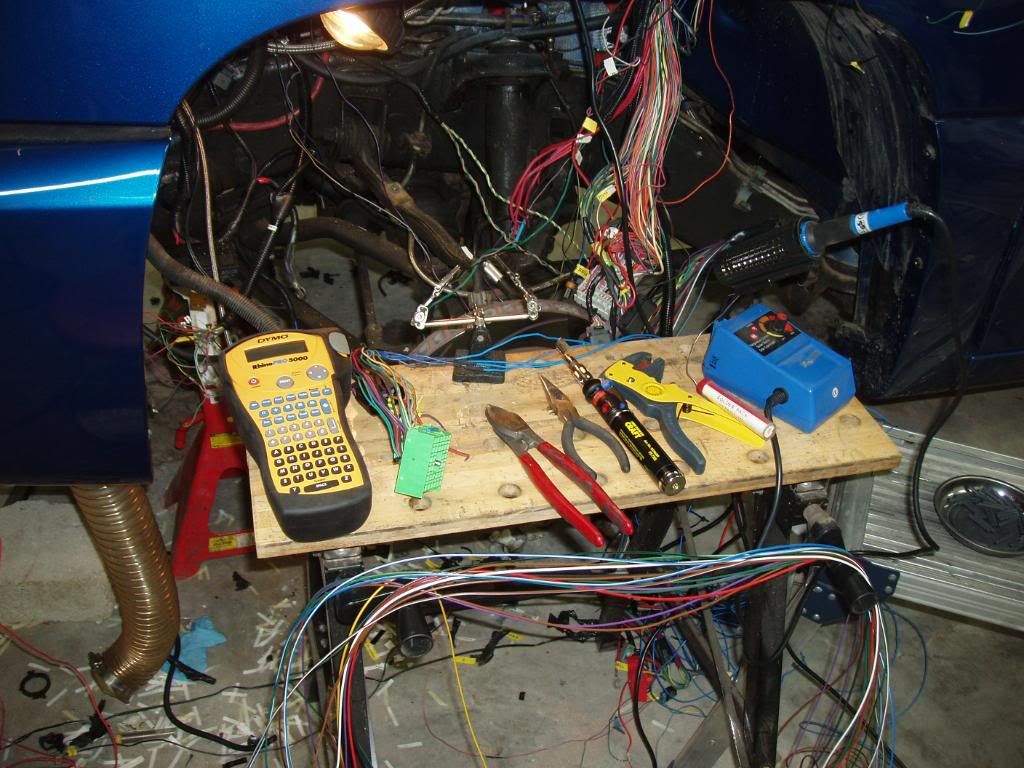

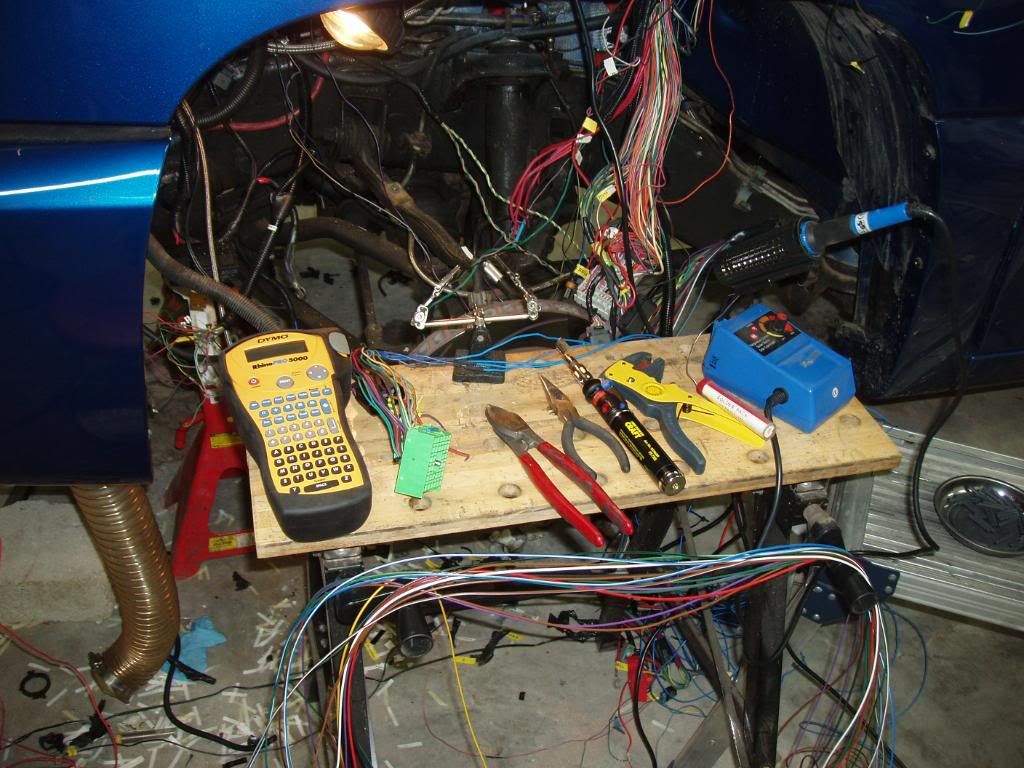

yeah I just added a bunch of wires labeled them and solder them up also used heat shrink with glue in it to make sure every joint was good and water tight.One problem I had when I first started was the white labels in the last picture weren't very sticky and some fell off which meant I had to trace those wires back, once I got the Dymo label machine everything was fine.

It's a slow time consuming job but I am pleased with the end results.

#10

TECH Enthusiast

iTrader: (2)

Join Date: Sep 2009

Location: ft worth texas

Posts: 598

Likes: 0

Received 0 Likes

on

0 Posts

Thanks, only problems I had was I missed a couple of grounds for the lights,I figured I got lucky considering the amount wires.

yeah I just added a bunch of wires labeled them and solder them up also used heat shrink with glue in it to make sure every joint was good and water tight.One problem I had when I first started was the white labels in the last picture weren't very sticky and some fell off which meant I had to trace those wires back, once I got the Dymo label machine everything was fine.

It's a slow time consuming job but I am pleased with the end results.

yeah I just added a bunch of wires labeled them and solder them up also used heat shrink with glue in it to make sure every joint was good and water tight.One problem I had when I first started was the white labels in the last picture weren't very sticky and some fell off which meant I had to trace those wires back, once I got the Dymo label machine everything was fine.

It's a slow time consuming job but I am pleased with the end results.

Damn, you def got more patience then I'd ever have!

Damn, you def got more patience then I'd ever have!