Stall install, How'd u plumb? + Tune tables

#1

I threw this up in both Tuning a.w.a. here in Drlvetrain. Whichever 1 people reply to, I'd appreciate whichever thread has the info.

My 258mm 2600 stall CircleD & FLT Level 7 will be goin in soon. It's not the mechanical that worries me. I know I'll be doin on my back, so getting it high up as possible to get tranny to clear the bottom of truck is a must.

Actually, I received sound advice from someone thru a PM.

Any tables that people can throw up that I can view their tuning for stall would be helpful. I have HPT Pro. Even if I can see comparison of where it started to where it's at now.

A concern:

Seating convertor:The convertor has to be seated & isn't there a click, click when convertor seats? That info is the main thing I'm concerned w/. on the mechanical side.

Other than that, it's mostly choice.

Like do I wanna run AN for TruCool 40K or not, but that's being covered elsewhere in 2 other threads by Billy. I've read 3/8" inverted flare is used going into the TruCool. If I can swing it, I wanna do AN route.

I know Krambo used 25' -6AN on his install. I know Cody did it too.

Anyone use -AN to replace all lines to / fro whole tranny circuit? It's not my goal to duplicate Billy's "Plumb a TruCool" thread.

If ya want just post pics, p/n's, & what co. you went w/. either in his thread or here. I also would like to see any pics if u modified stock lines too. If u left lines all stock, I don't need those.

My 258mm 2600 stall CircleD & FLT Level 7 will be goin in soon. It's not the mechanical that worries me. I know I'll be doin on my back, so getting it high up as possible to get tranny to clear the bottom of truck is a must.

Actually, I received sound advice from someone thru a PM.

Any tables that people can throw up that I can view their tuning for stall would be helpful. I have HPT Pro. Even if I can see comparison of where it started to where it's at now.

A concern:

Seating convertor:The convertor has to be seated & isn't there a click, click when convertor seats? That info is the main thing I'm concerned w/. on the mechanical side.

Other than that, it's mostly choice.

Like do I wanna run AN for TruCool 40K or not, but that's being covered elsewhere in 2 other threads by Billy. I've read 3/8" inverted flare is used going into the TruCool. If I can swing it, I wanna do AN route.

I know Krambo used 25' -6AN on his install. I know Cody did it too.

Anyone use -AN to replace all lines to / fro whole tranny circuit? It's not my goal to duplicate Billy's "Plumb a TruCool" thread.

If ya want just post pics, p/n's, & what co. you went w/. either in his thread or here. I also would like to see any pics if u modified stock lines too. If u left lines all stock, I don't need those.

#2

Youll be able to tell when the converter seats, its not seated until the converter feet are about an inch and a half inside the bellhousing, if its flush then the converter is not seated into the pump. The big harbour freight jackstands is what I use to get the truck up nice and high.

#3

I have a gauge for that

iTrader: (42)

Joined: Jan 2006

Posts: 16,266

Likes: 394

From: Huntsville, AL

You can feel the converter when it is fully seated onto the input shaft, it spins very easily. If its not seated fully it will still spin easily but will make a grinding noise since it isnt all the way on there.

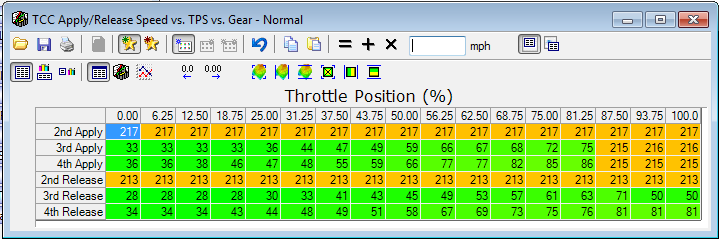

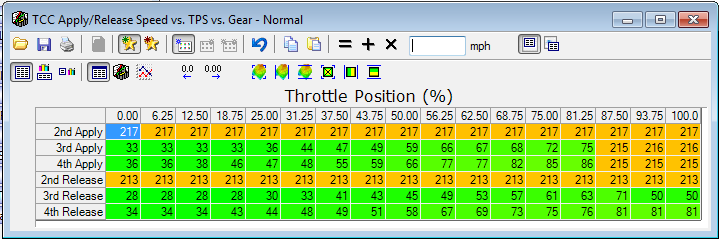

heres my table for my PI 2600 triple disc

Also trans shift table:

TCC settings are very touchy feely though, I spent weeks tweaking mine so it locks where I want it. I also had to redo my trans shift table when I put in the torque converter.

I just slid my trans under my truck since im lifted

I was also able to sit on my *** instead of some other akward position when putting in the bell housing bolts

heres my table for my PI 2600 triple disc

Also trans shift table:

TCC settings are very touchy feely though, I spent weeks tweaking mine so it locks where I want it. I also had to redo my trans shift table when I put in the torque converter.

I just slid my trans under my truck since im lifted

I was also able to sit on my *** instead of some other akward position when putting in the bell housing bolts

#4

Thanks for replies guys, keep em coming.

Cody, I've got some 5ton SnapOn stands, I just thought I'd go all the way up.

I don't have a tranny jack, just a 2 1/2 Lincoln (same as a SnapOn YA642). I don't have specs but it goes up pretty far.

Hopefully I get my best friend Joe to help muscle it up / down. I'd hate to drop it off jack if I'm doin myself. Unless someone knows a way to hold it on that style jack. 1 day I hope to get a nice trans jack, like an OTC.

Cody, I've got some 5ton SnapOn stands, I just thought I'd go all the way up.

I don't have a tranny jack, just a 2 1/2 Lincoln (same as a SnapOn YA642). I don't have specs but it goes up pretty far.

Hopefully I get my best friend Joe to help muscle it up / down. I'd hate to drop it off jack if I'm doin myself. Unless someone knows a way to hold it on that style jack. 1 day I hope to get a nice trans jack, like an OTC.

Last edited by fastnblu; 04-19-2010 at 10:44 PM.

#5

I have a gauge for that

iTrader: (42)

Joined: Jan 2006

Posts: 16,266

Likes: 394

From: Huntsville, AL

I dont have a tranny jack either (the adapter i bought wouldnt fit), but I took two pieces of 1x1' pieces of plywood and put them on opposite sides of some 4x4 posts I had laying around and put a nail into each to hold the thing together. It gave about 5" of more lift and a big surface to support the tranny on, and only took about 3 minutes to make.

#6

For the converter seating, just measure the distance from the bellhousing to the converter pads. It should be somewhere around 1". You can dig up FLT's thread with the exact specs.

BTW, why do you only

BTW, why do you only

#7

I dont have a tranny jack either (the adapter i bought wouldnt fit), but I took two pieces of 1x1' pieces of plywood and put them on opposite sides of some 4x4 posts I had laying around and put a nail into each to hold the thing together. It gave about 5" of more lift and a big surface to support the tranny on, and only took about 3 minutes to make.

I think u forgot to finish your thought Michael.

Trending Topics

#9

Cause I'm not lookin to kill my mileage, just want a lil above stock. I DD it ~160 miles / wk., mostly city or a mix style. Plus, I drive in winter. I did it more for durability.