TECH: Gearing GCSD3742's Truck

#11

Yup the trutrac is a nice piece, thats a 14 bolt unit MUCH bigger than the 10 bolt we all have, this is the 10 bolt

and congrats looks like the truck is coming along nicely

#13

TECH Addict

iTrader: (3)

Join Date: Dec 2006

Location: Alvin, Texas

Posts: 2,826

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the comps gentlemen. I know that I will have a competitive ride, but I know I will never reach the stamina that most trucks have now like a turbo or the juice. I'd like to learn what the truck can do without making an experiment out of it. I try and keep it conservative since I have a house note like many to take care of.

#14

Here is a shot of the new guts going it.

Now to get technical:

The ring gear bolts are a left hand thread and require a 3/4 inch socket. The torque spec for them is 65 ft.lbs. There are 10 of them, and they need to be tightened in a criss-cross pattern.

Now to get technical:

The ring gear bolts are a left hand thread and require a 3/4 inch socket. The torque spec for them is 65 ft.lbs. There are 10 of them, and they need to be tightened in a criss-cross pattern.

#15

Here is a shot of the new guts going it.

Now to get technical:

The ring gear bolts are a left hand thread and require a 3/4 inch socket. The torque spec for them is 65 ft.lbs. There are 10 of them, and they need to be tightened in a criss-cross pattern. Oh, and the use of threadlocker is VERY important.

Now to get technical:

The ring gear bolts are a left hand thread and require a 3/4 inch socket. The torque spec for them is 65 ft.lbs. There are 10 of them, and they need to be tightened in a criss-cross pattern. Oh, and the use of threadlocker is VERY important.

#17

TECH Addict

iTrader: (3)

Join Date: Dec 2006

Location: Alvin, Texas

Posts: 2,826

Likes: 0

Received 0 Likes

on

0 Posts

Here is a shot of the new guts going it.

Now to get technical:

The ring gear bolts are a left hand thread and require a 3/4 inch socket. The torque spec for them is 65 ft.lbs. There are 10 of them, and they need to be tightened in a criss-cross pattern. Oh, and the use of threadlocker is VERY important.

Now to get technical:

The ring gear bolts are a left hand thread and require a 3/4 inch socket. The torque spec for them is 65 ft.lbs. There are 10 of them, and they need to be tightened in a criss-cross pattern. Oh, and the use of threadlocker is VERY important.

Question from the novice...what is that gold stuff in the gears? Or is that just glare?

#19

TECH Apprentice

iTrader: (5)

Join Date: Jun 2007

Location: South side Houston,Texas

Posts: 348

Likes: 0

Received 0 Likes

on

0 Posts

Here is a shot of the new guts going it.

Now to get technical:

The ring gear bolts are a left hand thread and require a 3/4 inch socket. The torque spec for them is 65 ft.lbs. There are 10 of them, and they need to be tightened in a criss-cross pattern. Oh, and the use of threadlocker is VERY important.

Now to get technical:

The ring gear bolts are a left hand thread and require a 3/4 inch socket. The torque spec for them is 65 ft.lbs. There are 10 of them, and they need to be tightened in a criss-cross pattern. Oh, and the use of threadlocker is VERY important.

#20

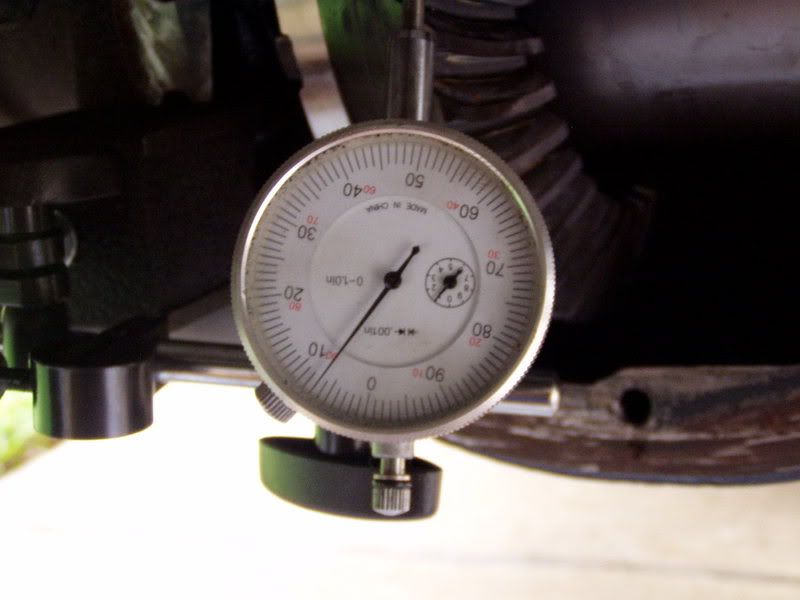

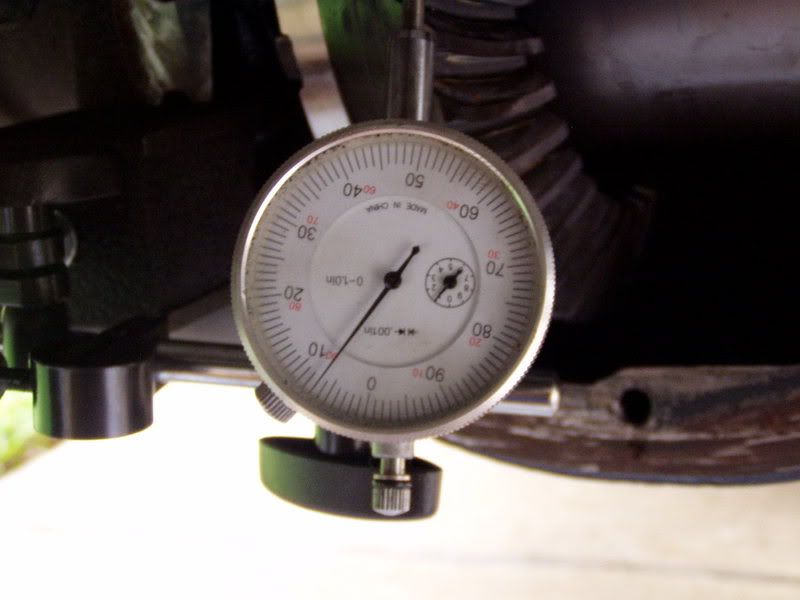

Alright, before stabbing everything in, I had to check and double check the pinion shim thickness. Since I have done 4.10s MANY times, I know that .035" to .037" shim works.

Once the pinion is in, I install the differential and check the backlash. The specs for these gears is 6-10 thousanths. This one hit right at 7 thousanths.

Close up:

Once the pinion is in, I install the differential and check the backlash. The specs for these gears is 6-10 thousanths. This one hit right at 7 thousanths.

Close up: