Death of an LY2

#1

Here is the death of an engine from just plain neglect... it's an LY2 4.8 out of a 2007 GMC 1/2 ton. I bought it a couple months back for $100 complete, throttle body to oil pan. The engine was "seized" according to the guy selling it. It was a company truck with around 140000 miles on it. One day he said it started making noise, so he checked the oil and it was a quart low. He filled it up with oil and went for a drive. Along his way the DIC started flashing low oil pressure and the gauge dropped off. He pulled over, shut it down, then restarted it and it built pressure so he continued on. The next morning the same scenario occured but it stalled..... and that was the end. The starter would not turn it over.

This is what I got to see when I popped the valve covers and valley cover off.

Looks nice huh....... No wonder it seized. The crap in it is the consistency of a regular chassis grease...... pretty hard to pump what it now a gell and no longer a liquid.

Surprisingly the cylinders look pretty good with no wear or ridge to note :

And the chambers look equally as normal:

But the lifters...... yeah I won't try and reuse lol:

And the only reasons I bought it of course as it is a donor for my a top end swap on my LQ9 I am putting in my 04 2500 LD:

As long as the heads are rebuildable cores.... which I am quite sure they are, I am happy with it. Hell even if I all I got was the intake and the rest was garbage that's okay too.

If I have time I will pop off the oil pan and take a look at the rotating assembly. The block may actually be salvageable but I have my doubts depending on what spun and caused it to lock up. If it was a main it's probably just scrap metal.

This is what I got to see when I popped the valve covers and valley cover off.

Looks nice huh....... No wonder it seized. The crap in it is the consistency of a regular chassis grease...... pretty hard to pump what it now a gell and no longer a liquid.

Surprisingly the cylinders look pretty good with no wear or ridge to note :

And the chambers look equally as normal:

But the lifters...... yeah I won't try and reuse lol:

And the only reasons I bought it of course as it is a donor for my a top end swap on my LQ9 I am putting in my 04 2500 LD:

As long as the heads are rebuildable cores.... which I am quite sure they are, I am happy with it. Hell even if I all I got was the intake and the rest was garbage that's okay too.

If I have time I will pop off the oil pan and take a look at the rotating assembly. The block may actually be salvageable but I have my doubts depending on what spun and caused it to lock up. If it was a main it's probably just scrap metal.

Last edited by 1994Vmax; 11-17-2012 at 07:16 PM.

#3

Yeah I was happy. I have the complete coil packs with brackets and harness, valve covers of course and then all the rest of the engine. The accessory drive is about the only thing that wasn't included with it. The guy bought a complete drop in out of a rolled van so he needed almost nothing from this engine. I would assume someone deleting AFM from a 5.3 could use the valley cover and whatnot as well. Scouring the local buy/sell ( called Kijiji, it's a nice layout compared to craigslist) pays off once and while.

#5

I have a gauge for that

iTrader: (42)

Joined: Jan 2006

Posts: 16,266

Likes: 394

From: Huntsville, AL

Man just take a low power pressure washer to the heads to get the top stuff off, spray some engine degreaser or oven cleaner in there to let sit and hit it with the pressure washer again and you are good to go!

Might not be that easy on the block...

Might not be that easy on the block...

#7

And yes, the odd oil change probably would have done wonders. The guy said they changed oil in this regularily and used 15W40 diesel oil in it....... but I really don't see it. Maybe his "regularily" and mine differ.

The only negative was one sheared exhaust manifold bolt that is broken about a thread down into the head. It had 2 broken ones when I got it but the other had a stub sticking out so I just turned it out with vice grips. I could use a reverse drill bit at home but since they are going to get cleaned and crack checked at my buddies head shop he can do that for me instead. After that I want to do some minor clean up work on them ( no porting as I don't know what I am doing and have no flow bench) and then get them rebuilt with new springs and probably stainless valves. It's overkill as it will be N/A, but that is only for now.

I did think I might keep the rockers actually and just do the trunion upgrade on them..... or just use the ones off the LQ9 since they have a 1/4 of the mileage and aren't crud city.

Yeah I remember you beating that poor little guy in your truck, lol. I have to pull apart the bottom end of this one and take some photos. I can only imagine how wonderful it will look.

Last edited by 1994Vmax; 11-17-2012 at 08:29 PM.

Trending Topics

#8

I use the local car wash to do the same. The guy that runs it says as long as I don't spray grease all over the place he is cool with it. I just do it as close to the drain as possible and spray down the stall when I am done. I usually spend at least $5 some time more if I wash my truck down. The soapy water cycle uses hot water which is why I like going there. Adding heat to the pressure is the best way to clean greasy oily stuff. That's how the engine shop does it in there cleaner cabinet. but this is 1/10 of the cost.

The water goes to a settling tank any way so the grease and soap get separated.

Some places will get mad and tell you not to do it. There afraid that they will have to clean up your greasy mess.

By law these places have to me standards and can't just let the water run off go right down the drain. So Don't let them fool you.

The water goes to a settling tank any way so the grease and soap get separated.

Some places will get mad and tell you not to do it. There afraid that they will have to clean up your greasy mess.

By law these places have to me standards and can't just let the water run off go right down the drain. So Don't let them fool you.

#9

I know and I have done it many a time in the past at the car washes as well. They all have sumps/settling ponds in the car wash somewhere. Most post not to wash greasy parts or whatnot so it's easier to just not do it and avoid any issues. That said I can do it with hot water and high pressure at the old engine shop too..... and then maybe throw it in the glass beader for a new part look lol.

#10

And the finale:

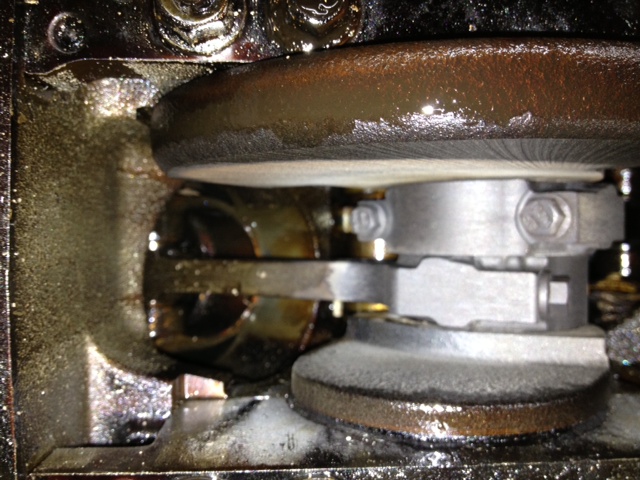

Here is what I saw pulling the pan:

And the sump:

Looks normal for this mess:

Little warm anyone?????? Lol:

Main cap off:

Cap itself with a little metal:

It turns now with those two rods loose, and that didn't spin..... no...... Lol:

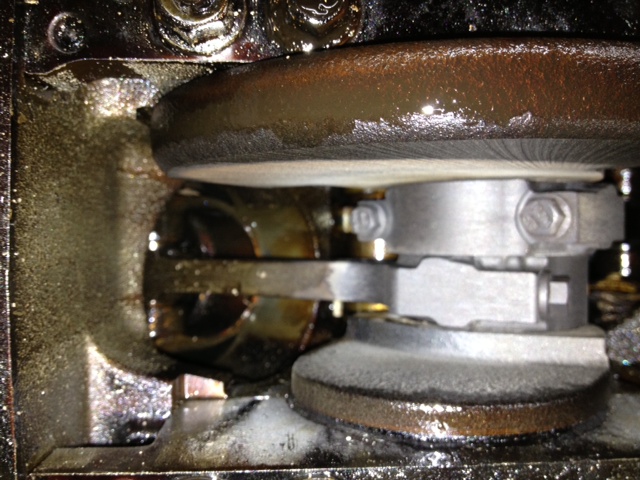

Bearings welded on the crank:

Bearings off:

Bearing Journal:

Isn't that nice:

Honestly it surprises me as I am pretty sure the block is fine. The main didn't spin the bearings and subsequently didn't actually get hot. Toss a 5.3 rotating assembly in and call it a day!

Here is what I saw pulling the pan:

And the sump:

Looks normal for this mess:

Little warm anyone?????? Lol:

Main cap off:

Cap itself with a little metal:

It turns now with those two rods loose, and that didn't spin..... no...... Lol:

Bearings welded on the crank:

Bearings off:

Bearing Journal:

Isn't that nice:

Honestly it surprises me as I am pretty sure the block is fine. The main didn't spin the bearings and subsequently didn't actually get hot. Toss a 5.3 rotating assembly in and call it a day!