I Need Your Help. 408 Stroker Wont Run.

#51

100% Redneck

I see you have a 408 as well, what is your truck running for oil pressure? I feel like mine is lower then it should be, idles between 30-35 at about 1500/2000 RPM it goes to 40 and steadily goes up which is good. I just feel the idle pressure is pretty low, probably me just over thinking it.

#53

Still have a lot of kinks to work out but it is running well all things considered.

Side note I had no idea how much header wrap smoked!!

The following users liked this post:

00pooterSS (10-27-2020)

#54

Drive it some while keeping an eye on the oil pressure then do an oil change to replace the break in oil, cut and inspect the filter, if there are no signs of bearing materiel... you're probably good to go. Your builder may have assembled with the clearances toward the loose side, but within the tolerance range. A lot of builders will recommend an oil viscosity based on the final rod/main bearing clearances.

#55

TECH Fanatic

With my oil up to temp at 210* my oil pressure at idle is a tad under 45psi. I run a melling 296 pump mainly because I run a decent sized oil cooler with -6 lines under my trans cooler.

I also run a little tighter bearing clearances to help keep things a little more stable at high rpm.

I run mobil 1 5-30 oil

I also run a little tighter bearing clearances to help keep things a little more stable at high rpm.

I run mobil 1 5-30 oil

#56

With my oil up to temp at 210* my oil pressure at idle is a tad under 45psi. I run a melling 296 pump mainly because I run a decent sized oil cooler with -6 lines under my trans cooler.

I also run a little tighter bearing clearances to help keep things a little more stable at high rpm.

I run mobil 1 5-30 oil

I also run a little tighter bearing clearances to help keep things a little more stable at high rpm.

I run mobil 1 5-30 oil

I am running a 296 Meiling pump as well but I put one of the different springs in it (I don't remember the colors, I only know I didn't put the 70 psi spring in haha).

I have -6 cooler lines, but I am running them to the stock cooler, and I am using a lingenfielder adapter plate. They have - 10 fittings coming off the block and I reduced them down to -6 because I felt -10 was way to big for my setup.

#57

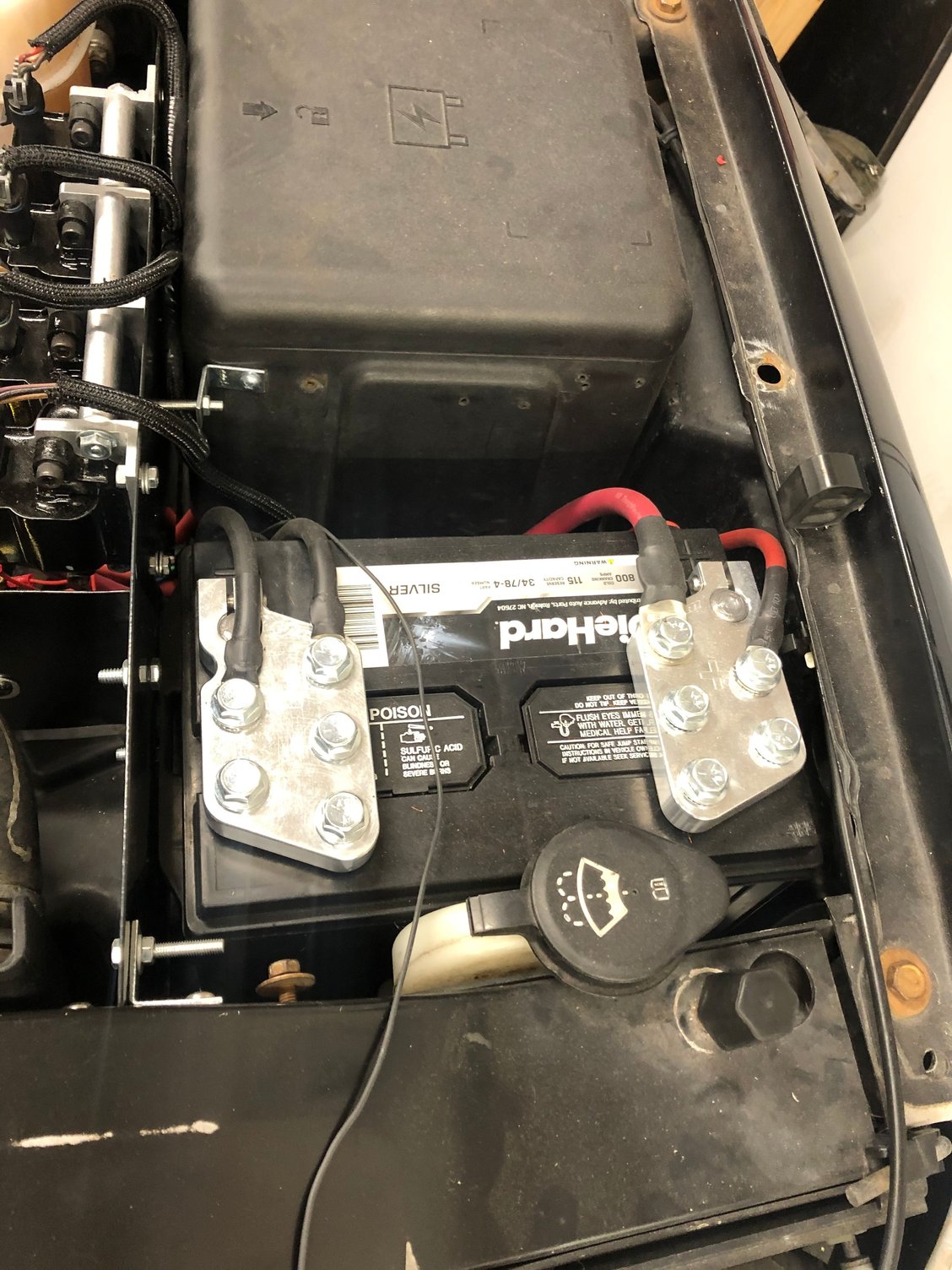

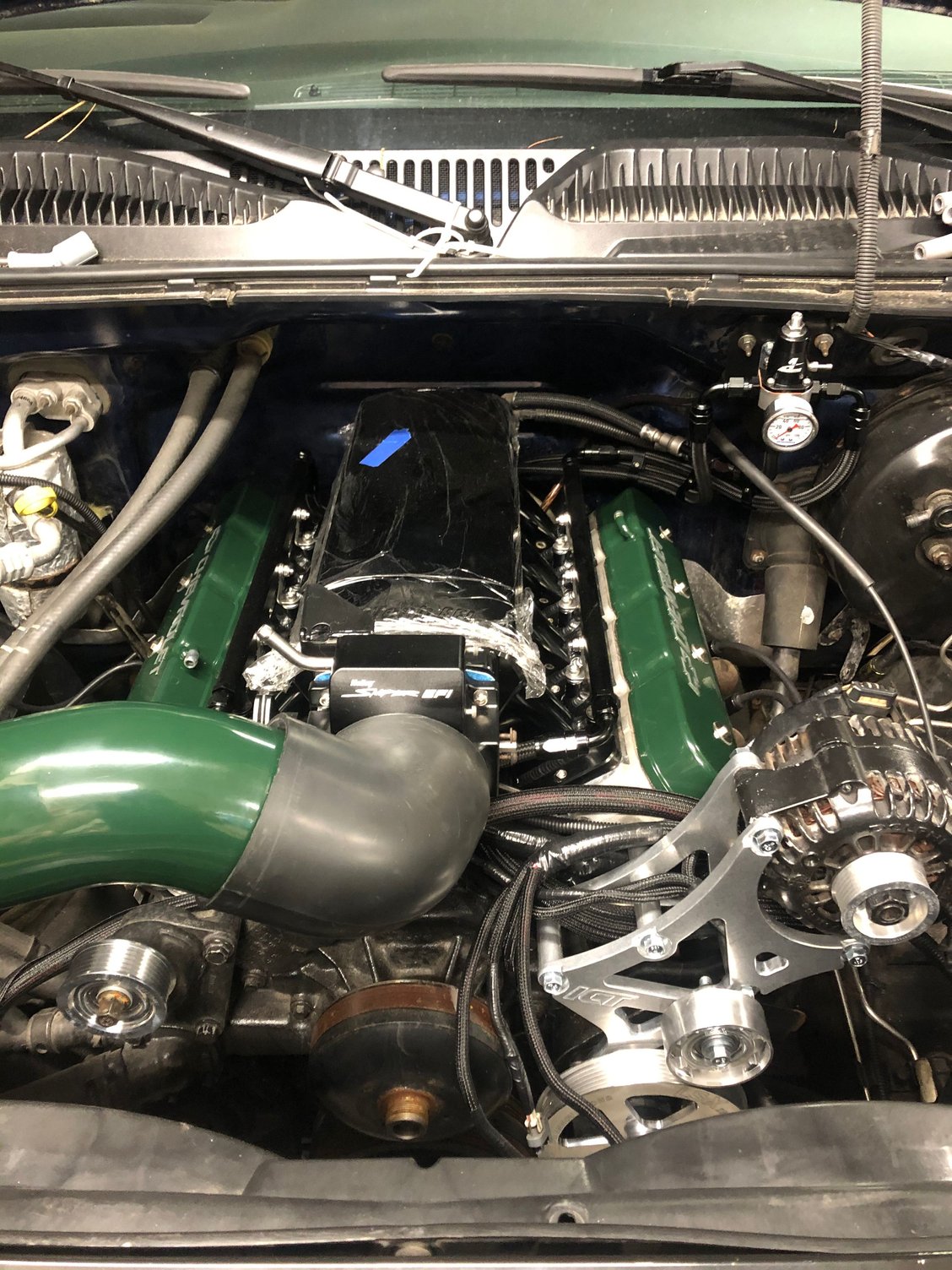

Hey guys, popping in to give an update. Truck is up and running. I still need to break the motor in officially but I have to put a new hydro boost/master cylinder and brakes on before I drive it. It has moved up and down the driveway on its own power.

Of course I decided I wanted to change the location of my wiring harness, so I pulled the intake to rework everything.

Currently still having trouble with intake piping, I did order boots from the website everyone suggested. Itís just a matter of getting them to fit right.

I have attached a few photos of the other truck as well.

Of course I decided I wanted to change the location of my wiring harness, so I pulled the intake to rework everything.

Currently still having trouble with intake piping, I did order boots from the website everyone suggested. Itís just a matter of getting them to fit right.

I have attached a few photos of the other truck as well.

The following users liked this post:

dantheman1540 (12-07-2020)

The following users liked this post:

dantheman1540 (12-07-2020)

#60

TECH Junkie

iTrader: (40)

IT ALL LOOKS SOOOO GOODDD

(caps for yelling, yes I'm yelling it)

However, might I suggest some MSD plug wires, they have poseable boots that allow you to bend the boot to the angle you need so that it stays of the headers. I've had them on a couple setups with headers and they work so damn good.

(caps for yelling, yes I'm yelling it)

However, might I suggest some MSD plug wires, they have poseable boots that allow you to bend the boot to the angle you need so that it stays of the headers. I've had them on a couple setups with headers and they work so damn good.