Lq4 built and started!......somethings not right

#102

TECH Junkie

Join Date: Jun 2014

Location: At the dump with a clutch

Posts: 3,135

Received 781 Likes

on

571 Posts

My cam specs are 218/222 on a 110+3 .587/.578 nothing major.

LY6 rods and pistons.

NNBS intake manifold

8.1l injectors

ls3 throttle body

pac racing springs

trunnion rocker upgrade

milled heads .030

comp cam push rods

shorty headers

How much horsepower you think this motor will make?

2600-2800 stall converter

4l80e

Ah man that sucks but nothing on these trucks is really hard to work on especially if you have already messed with everything at least once.

LY6 rods and pistons.

NNBS intake manifold

8.1l injectors

ls3 throttle body

pac racing springs

trunnion rocker upgrade

milled heads .030

comp cam push rods

shorty headers

How much horsepower you think this motor will make?

2600-2800 stall converter

4l80e

Ah man that sucks but nothing on these trucks is really hard to work on especially if you have already messed with everything at least once.

Not sure what It will make but my Tahoe is had a little smaller cam and similar bolt ons. Its snappy and has a ton of torque. Should get those big tires moving well.

#104

Launching!

Thread Starter

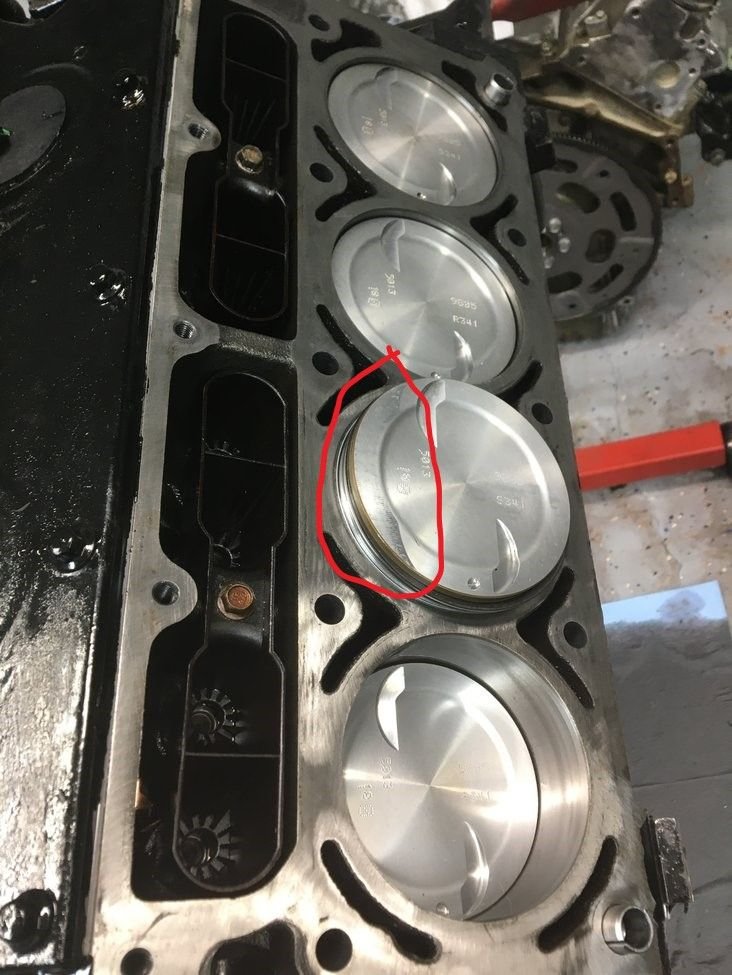

It did smack the head a couple times. That was the one with the bad rod bearing. Pictures are somewhere in this thread. Installer error.

got a new rod installed on that piston and waiting on new crankshaft now.

got a new rod installed on that piston and waiting on new crankshaft now.

#106

TECH Fanatic

iTrader: (6)

long as you take your time, dont have any distractions (ball game on tv, kids wanting something, wife sending you out) you will be fine

make a sheet showing each step then check it off as you go to the next step, use a marker or paint pen to mark fasteners as you torque them. keeping track of whats torqued is very important! make sure things are lined up and you dont force things in place with a hammer (some times a light tap with a rubber mallet is needed on main caps) just make sure bearings are seated properly before you tap anything

these engine are not really hard to assembly dont be in a rush keep track of torqued fasteners, have a quality torque wrench, use a bunch of assembly lube and check clearances on all the main and rod bearings. dont over think it

id take a good look at that piston make sure the top didnt bend or any thing check the top ring gap make sure its not tight

make a sheet showing each step then check it off as you go to the next step, use a marker or paint pen to mark fasteners as you torque them. keeping track of whats torqued is very important! make sure things are lined up and you dont force things in place with a hammer (some times a light tap with a rubber mallet is needed on main caps) just make sure bearings are seated properly before you tap anything

these engine are not really hard to assembly dont be in a rush keep track of torqued fasteners, have a quality torque wrench, use a bunch of assembly lube and check clearances on all the main and rod bearings. dont over think it

id take a good look at that piston make sure the top didnt bend or any thing check the top ring gap make sure its not tight

The following users liked this post:

Nick99Chevy (01-31-2020)

#107

Launching!

Thread Starter

All great advice there! Also buy a good engine stand. I suggest the 2,000lb one at harbor freight. I used the 1,000 and it is part of the reason this happened to me. Its a long story but the 1k stand is scary and I didn't want to rotate the motor unless I absolutely had to.

I checked it. Thankfully everything is good. I dont think it hurt it because the rod was so damn loose lol

long as you take your time, dont have any distractions (ball game on tv, kids wanting something, wife sending you out) you will be fine

make a sheet showing each step then check it off as you go to the next step, use a marker or paint pen to mark fasteners as you torque them. keeping track of whats torqued is very important! make sure things are lined up and you dont force things in place with a hammer (some times a light tap with a rubber mallet is needed on main caps) just make sure bearings are seated properly before you tap anything

these engine are not really hard to assembly dont be in a rush keep track of torqued fasteners, have a quality torque wrench, use a bunch of assembly lube and check clearances on all the main and rod bearings. dont over think it

id take a good look at that piston make sure the top didnt bend or any thing check the top ring gap make sure its not tight

make a sheet showing each step then check it off as you go to the next step, use a marker or paint pen to mark fasteners as you torque them. keeping track of whats torqued is very important! make sure things are lined up and you dont force things in place with a hammer (some times a light tap with a rubber mallet is needed on main caps) just make sure bearings are seated properly before you tap anything

these engine are not really hard to assembly dont be in a rush keep track of torqued fasteners, have a quality torque wrench, use a bunch of assembly lube and check clearances on all the main and rod bearings. dont over think it

id take a good look at that piston make sure the top didnt bend or any thing check the top ring gap make sure its not tight

#108

TECH Enthusiast

I used a 750lb engine stand for my 4.8l and it did the job just fine. You just really had to grab ahold of the block when you were rotating it over. These motors are much heavier then what Iím used to lol.

#110

Launching!

Thread Starter