LS6 Intake Swap

#1

Thread Starter

TECH Fanatic

iTrader: (3)

Joined: Oct 2003

Posts: 1,612

Likes: 0

From: Winston Salem NC

LS6 intake swap

Heres a brief write-up on what all Iíve encountered during my swap to the LS6 intake

Hopefully this will help others that would like to do this swap

There are a few ways you can go about this so itís kind of hard to make a step by step

type write-up

So I'll just stick to sharing my experience

Intake

You will need longer bolts or car bolts M6X100

110mm long

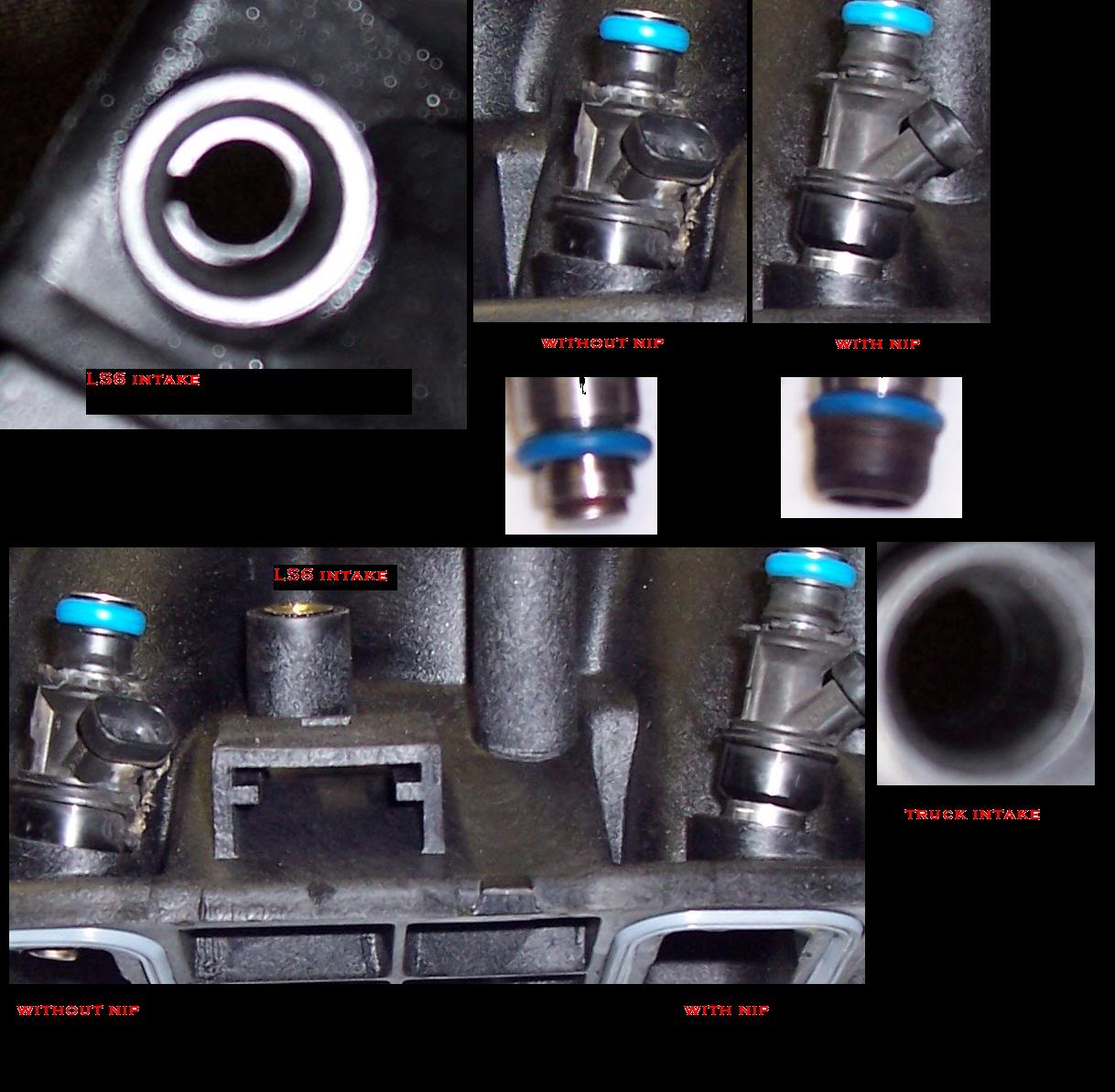

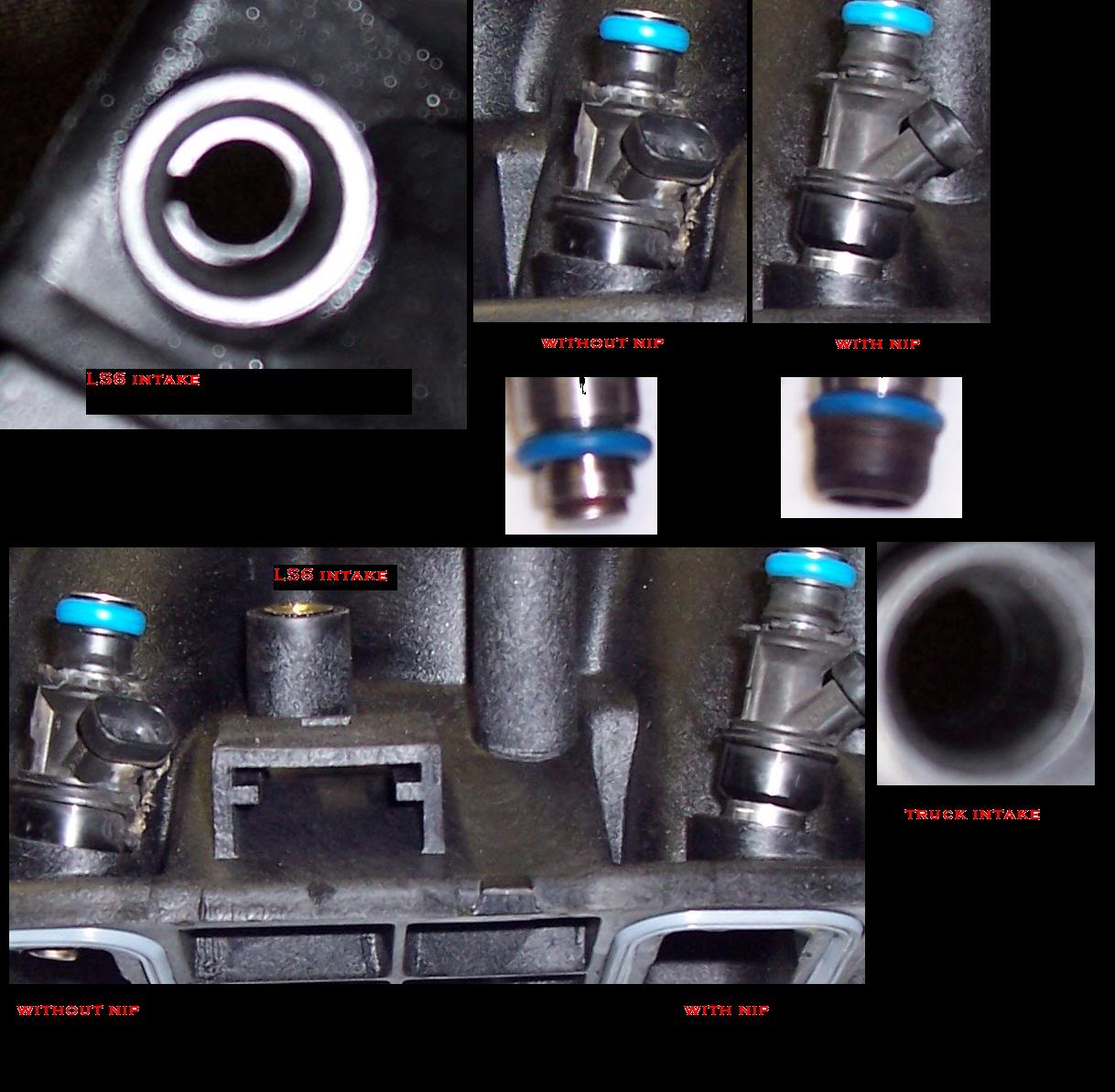

The ls6 intake doesnít have a nip that goes to the valve cover vent on the pass side

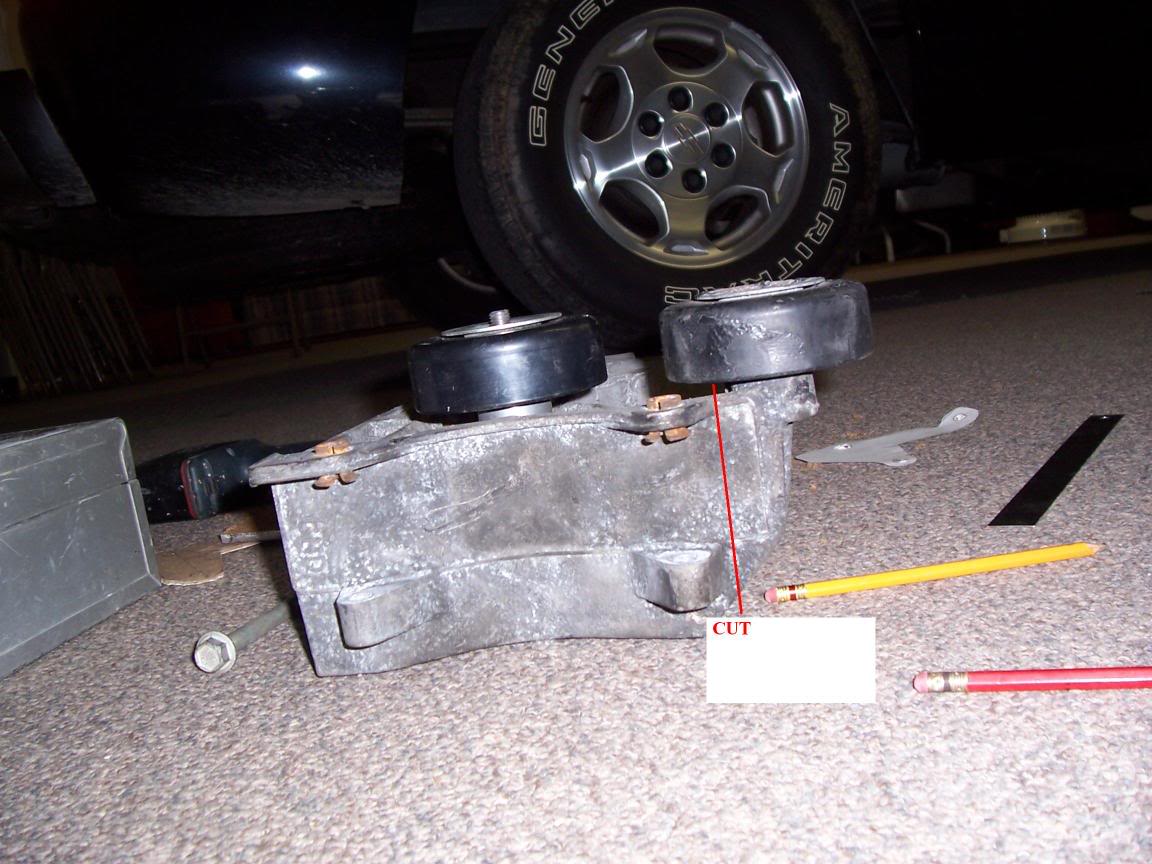

I cut away as shown below, drilled and tapped with a 1/8 npt tap for a brass fitting

(This was drilled at a slight angle)

You may be able to tap a fitting into the intake tube ďnot sure thoughĒ

Fuel rails and injectors

I made a bracket for the fuel rails

I used 1/8 X 1Ē steel stock, cut out for the injector bosses,

Spacers welded on, drilled and tapped the spacers, drilled for the intake bolts

and its good to go

InjectorsÖ

Facts

1 The truck injectors will not fit inside the injector bungs on the intake

2 The seal kit (o rings) part number between the car and truck injector is different

Heres why they donít fit

I removed the plastic tips on the injectors to clear the C shape at the bottom of the injector bung and replaced the lower Orings with the ones from an F body

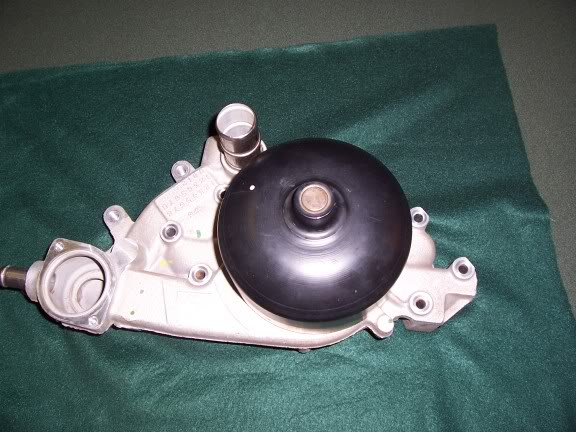

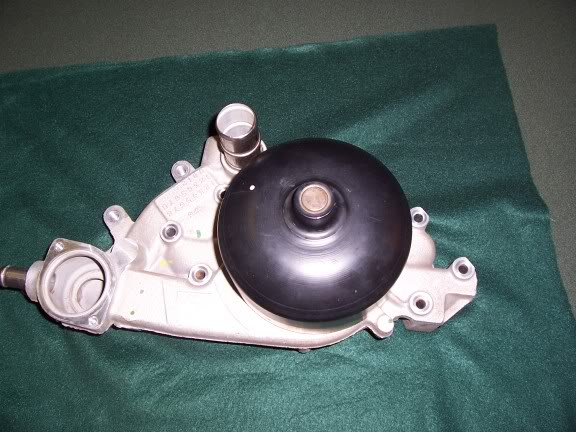

Water pump

There are basically 3 different style water pumps out there

The trucks' /press on pulley

The cars'/ press on pulley

And the 97 corvette, which has the bolt on pulley

Since the outlet on the truck WP is up high the TB will hit the upper outlet

(especially drive by wire TBs)

I believe the cable driven TBs can get away with just cutting down the upper outlet

"not sure though"

Mine is DBW

so I used the 97 vette WP

I got it from NAPA reman "part number 58-544"

And ordered a pulley from GM

This moves the outlet location to the lower boss, which will clear the TB

Whatís the significance in the bolt on pulley?

Simple, the difference in the truck and car accessories is different

The car accessories push the belt alignment back towards the engine.

The 97 vette WP will have to be spaced out approx. 3/4 to keep belt alignment in check.

The bolt on pulley allows spacing pretty easily

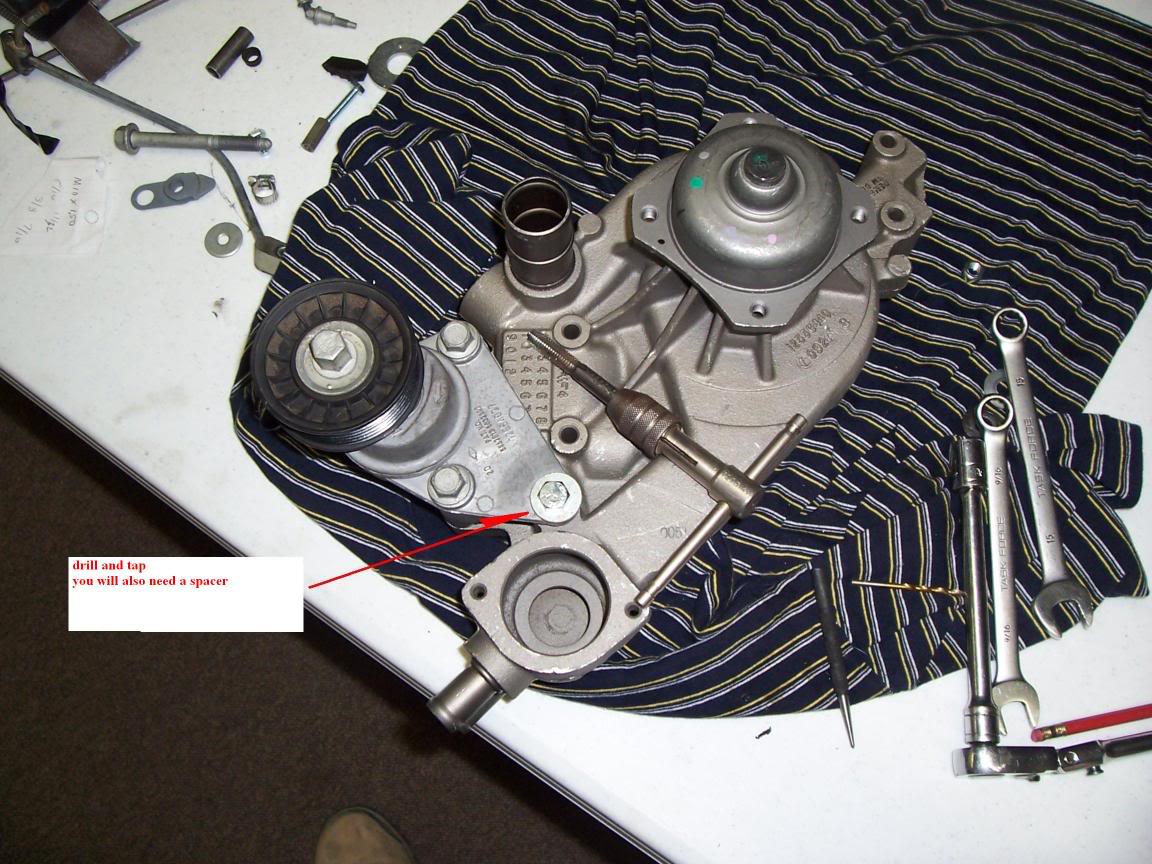

But still, thereís another issue,

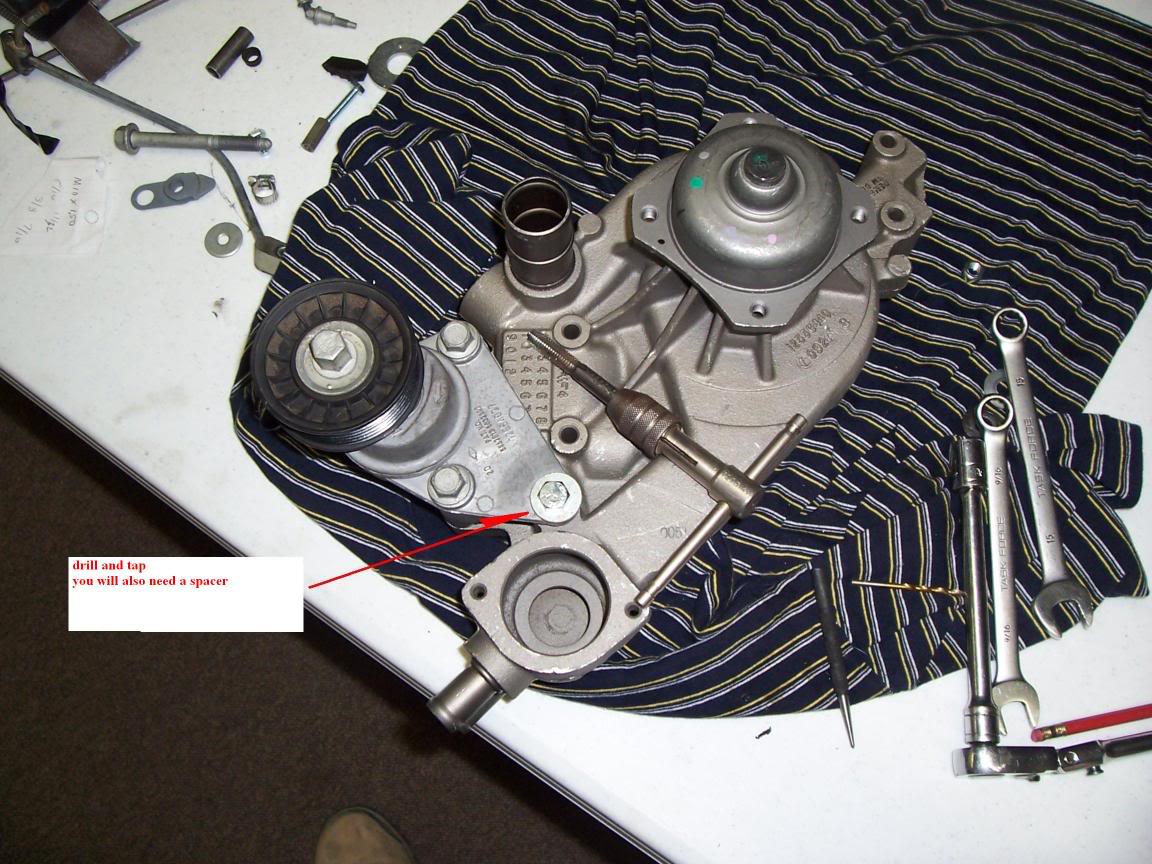

The tensioner bracket

The vette water pump has a boss there for the 3rd bolt but its not tapped

Thatís a simple fix though

Drill it, tap It, put a spacer between the tensioner and WP, and youíre done

Use caution though

You donít want to bust through into the WP

Heres a brief write-up on what all Iíve encountered during my swap to the LS6 intake

Hopefully this will help others that would like to do this swap

There are a few ways you can go about this so itís kind of hard to make a step by step

type write-up

So I'll just stick to sharing my experience

Intake

You will need longer bolts or car bolts M6X100

110mm long

The ls6 intake doesnít have a nip that goes to the valve cover vent on the pass side

I cut away as shown below, drilled and tapped with a 1/8 npt tap for a brass fitting

(This was drilled at a slight angle)

You may be able to tap a fitting into the intake tube ďnot sure thoughĒ

Fuel rails and injectors

I made a bracket for the fuel rails

I used 1/8 X 1Ē steel stock, cut out for the injector bosses,

Spacers welded on, drilled and tapped the spacers, drilled for the intake bolts

and its good to go

InjectorsÖ

Facts

1 The truck injectors will not fit inside the injector bungs on the intake

2 The seal kit (o rings) part number between the car and truck injector is different

Heres why they donít fit

I removed the plastic tips on the injectors to clear the C shape at the bottom of the injector bung and replaced the lower Orings with the ones from an F body

Water pump

There are basically 3 different style water pumps out there

The trucks' /press on pulley

The cars'/ press on pulley

And the 97 corvette, which has the bolt on pulley

Since the outlet on the truck WP is up high the TB will hit the upper outlet

(especially drive by wire TBs)

I believe the cable driven TBs can get away with just cutting down the upper outlet

"not sure though"

Mine is DBW

so I used the 97 vette WP

I got it from NAPA reman "part number 58-544"

And ordered a pulley from GM

This moves the outlet location to the lower boss, which will clear the TB

Whatís the significance in the bolt on pulley?

Simple, the difference in the truck and car accessories is different

The car accessories push the belt alignment back towards the engine.

The 97 vette WP will have to be spaced out approx. 3/4 to keep belt alignment in check.

The bolt on pulley allows spacing pretty easily

But still, thereís another issue,

The tensioner bracket

The vette water pump has a boss there for the 3rd bolt but its not tapped

Thatís a simple fix though

Drill it, tap It, put a spacer between the tensioner and WP, and youíre done

Use caution though

You donít want to bust through into the WP

#2

Thread Starter

TECH Fanatic

iTrader: (3)

Joined: Oct 2003

Posts: 1,612

Likes: 0

From: Winston Salem NC

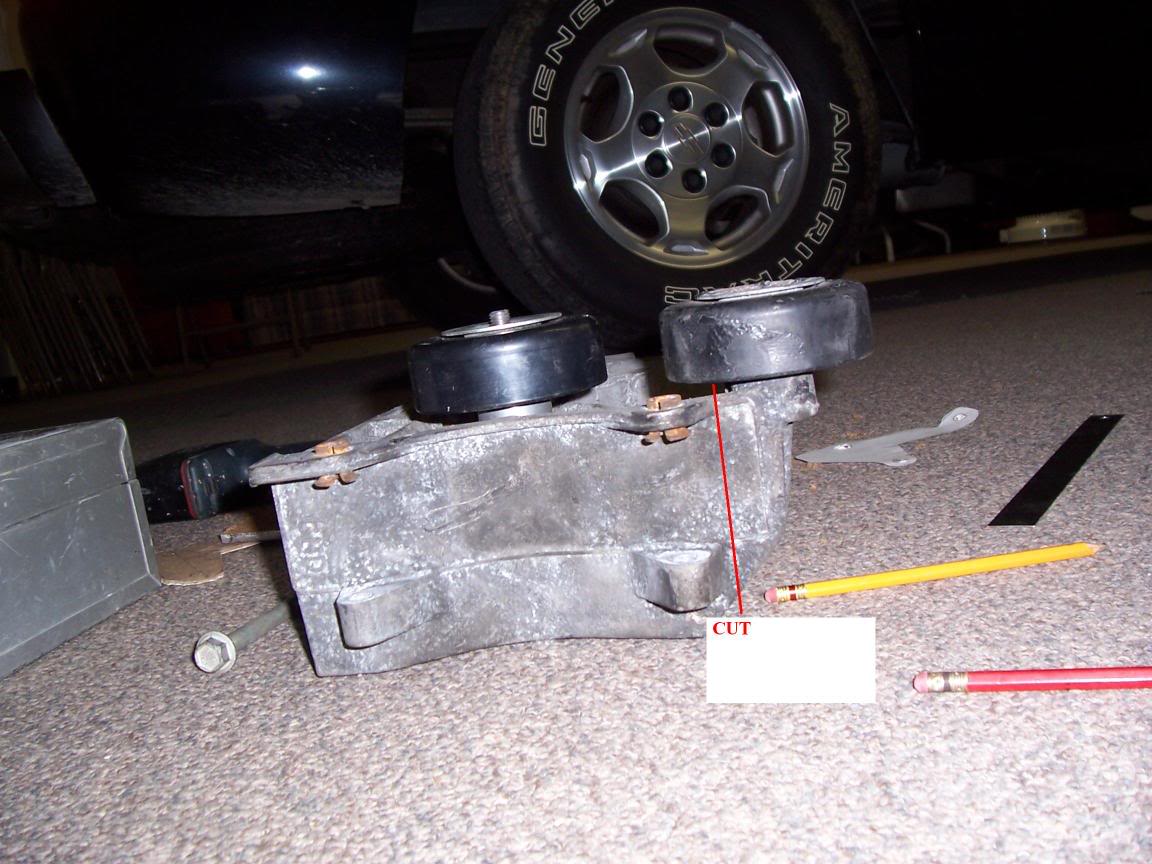

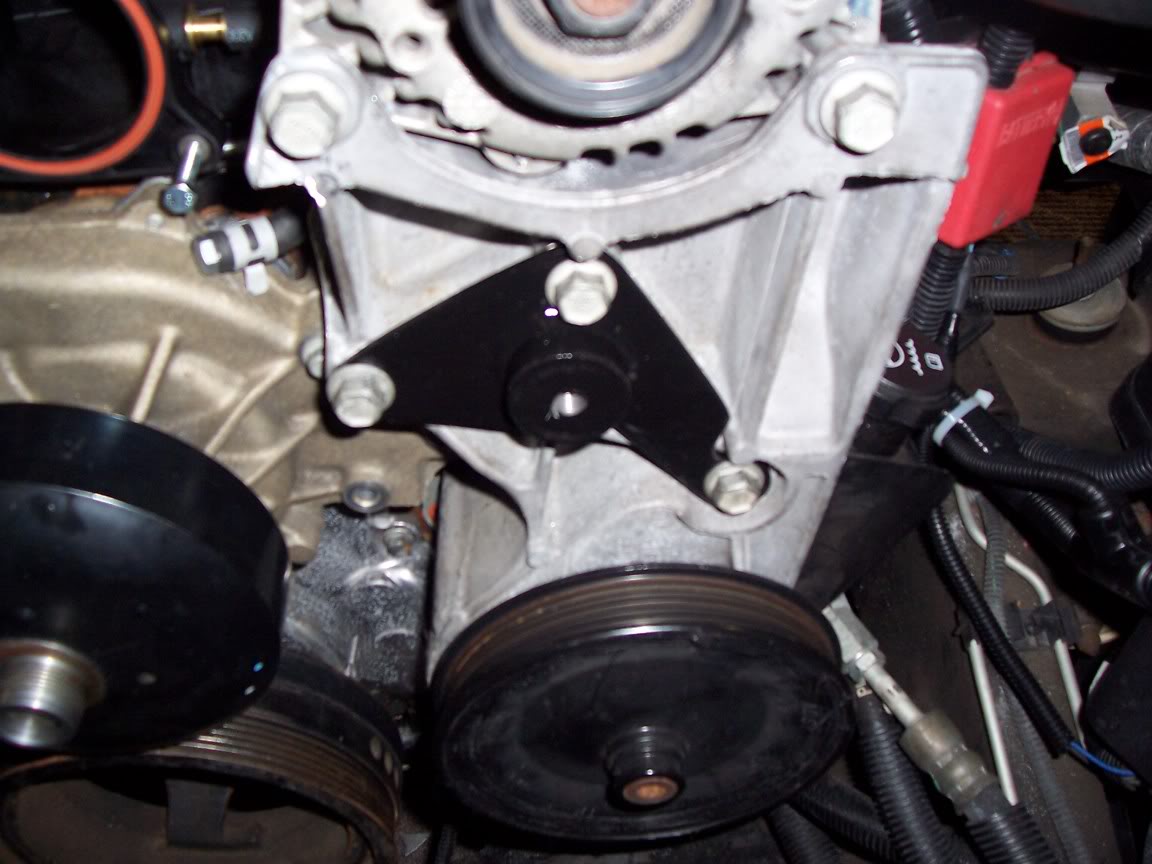

Idler pulley

The stock location of the idler pulley will not clear the TB

The pulley will need to be removed, relocated and the stock boss cut off for TB clearance

this is how mine looked after cutting

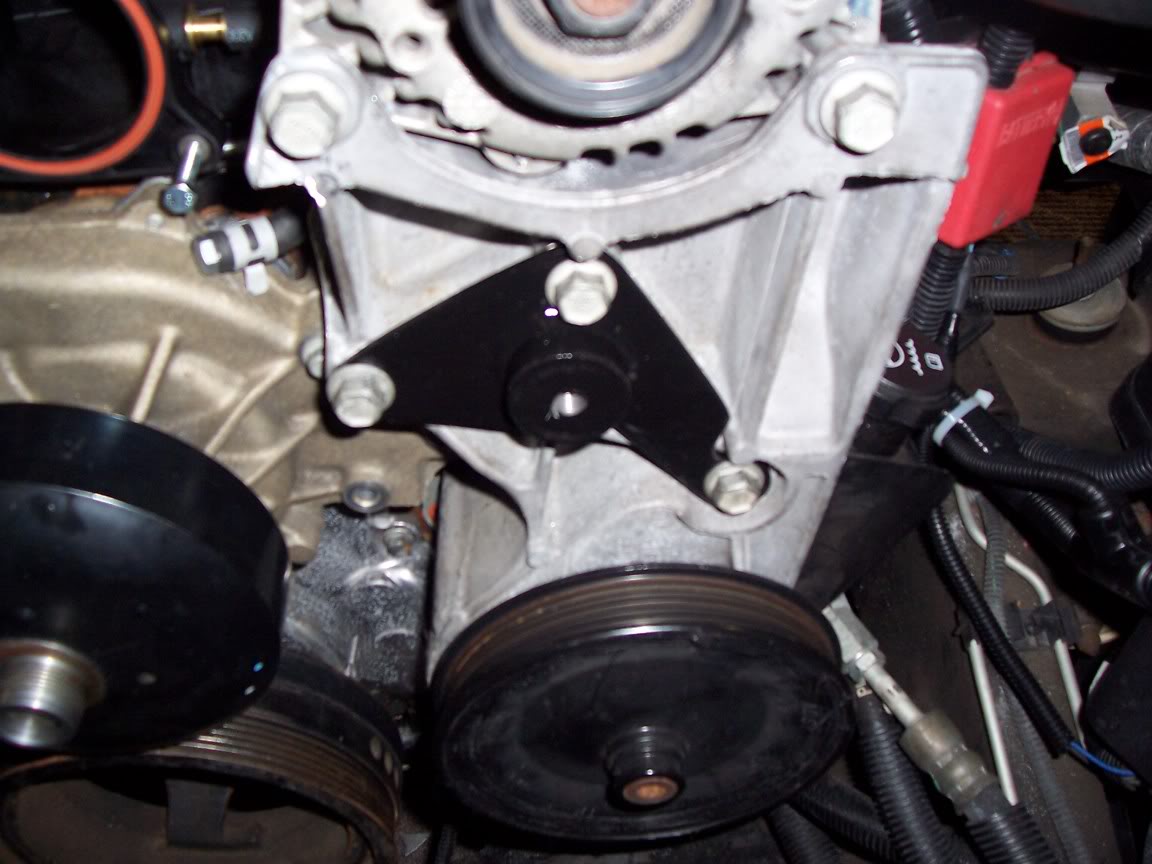

I originally bought the speartech bracket but it didnít work with the 97 vette WP

And belt routing

I made my own bracket to place the idler lower and more to the right

This lets me run the belt under the WP and clear the water pump outlet

Heres what I made

The speartech bracket will work fine if you have the equipment to modify the

WP like they do

This requires, to the best of my knowledge,

Cutting and welding the upper outlet tube to make it a 90*

And machining the water pump boss so it can be pressed in

OrÖdrilling and welding it in

I didnít have the tools to machine the water pump and donít like the idea of welding on the WP

Thats why I chose the 97 vette WP and making my own bracket

Heres what the belt routing will look like

Throttle body

There was one more clearance issue with the TB and WP

The bottom of the TB needs to be shaved a tiny bit to clear the WP housing

This can easily be done with a file or grinder

(This should be true with all truck TBs but Iím not certain)

EVAP

There is no place to connect the truck EVAP canister to the intake the way itís connected

To the truck manifold

I first removed the Oring on the outlet then I took the connector off the PCV hard line and clamped it to the outlet of the Canister

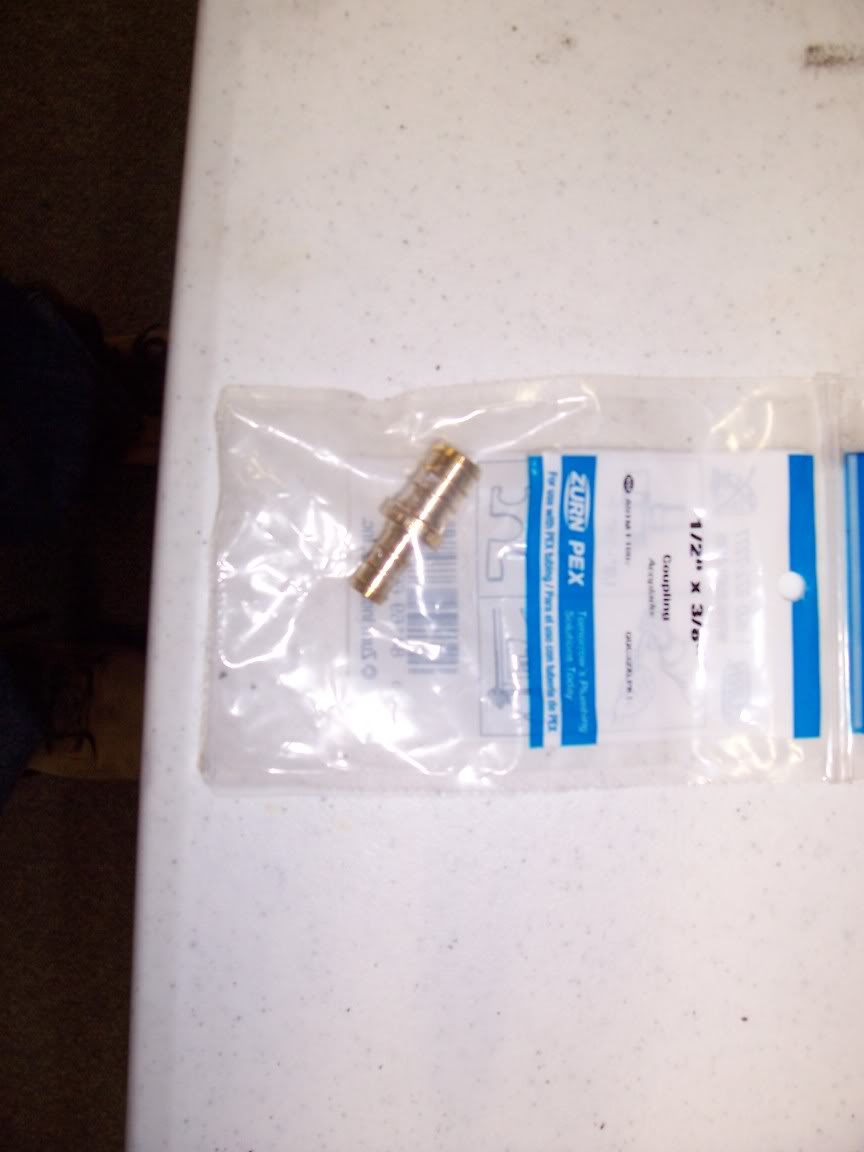

I then used a reducer Ĺ by 3/8

And connected it all together with a 5/16 fuel line to the brass nip on the driver side of the intake

PCV

For this I just ran a 3/8" transmission cooler line from the hard line to the pass side of the intake

Heres a pic of the vac lines

FPR

(Fuel pressure regulator, if equipped)

I used a vacume line attached to existing line with rtv

Back to the small nip at the very back of the intake

I do not have results yet, but will soon

What really made me do this swap

is the theories I've had based on the results

and powerband with my application

as well as the design of the truck intake itself.

It really came to the light when I compared Mattrem's dyno graph with mine

A 228/230 should pull higher than a 216/220

with everything else being basically the same.

I've also noticed this restriction in several other graphs I've seen

It appears that 5000 and 350hp is the magic numbers where the intake begins to run out of breath

I would also like to give Sportside a big thanks for getting my mind in the right direction with all of our back and forth PMs about reverse split cams, intake restrictions and so on

After presenting the results and theories to Richard@wcch , he seems to agree and is interested in seeing the results

Only one way to know for sure though, I should have track times and dyno graphs

to compare the 2 soon

I'll post results reguardless if its good or bad

The stock location of the idler pulley will not clear the TB

The pulley will need to be removed, relocated and the stock boss cut off for TB clearance

this is how mine looked after cutting

I originally bought the speartech bracket but it didnít work with the 97 vette WP

And belt routing

I made my own bracket to place the idler lower and more to the right

This lets me run the belt under the WP and clear the water pump outlet

Heres what I made

The speartech bracket will work fine if you have the equipment to modify the

WP like they do

This requires, to the best of my knowledge,

Cutting and welding the upper outlet tube to make it a 90*

And machining the water pump boss so it can be pressed in

OrÖdrilling and welding it in

I didnít have the tools to machine the water pump and donít like the idea of welding on the WP

Thats why I chose the 97 vette WP and making my own bracket

Heres what the belt routing will look like

Throttle body

There was one more clearance issue with the TB and WP

The bottom of the TB needs to be shaved a tiny bit to clear the WP housing

This can easily be done with a file or grinder

(This should be true with all truck TBs but Iím not certain)

EVAP

There is no place to connect the truck EVAP canister to the intake the way itís connected

To the truck manifold

I first removed the Oring on the outlet then I took the connector off the PCV hard line and clamped it to the outlet of the Canister

I then used a reducer Ĺ by 3/8

And connected it all together with a 5/16 fuel line to the brass nip on the driver side of the intake

PCV

For this I just ran a 3/8" transmission cooler line from the hard line to the pass side of the intake

Heres a pic of the vac lines

FPR

(Fuel pressure regulator, if equipped)

I used a vacume line attached to existing line with rtv

Back to the small nip at the very back of the intake

I do not have results yet, but will soon

What really made me do this swap

is the theories I've had based on the results

and powerband with my application

as well as the design of the truck intake itself.

It really came to the light when I compared Mattrem's dyno graph with mine

A 228/230 should pull higher than a 216/220

with everything else being basically the same.

I've also noticed this restriction in several other graphs I've seen

It appears that 5000 and 350hp is the magic numbers where the intake begins to run out of breath

I would also like to give Sportside a big thanks for getting my mind in the right direction with all of our back and forth PMs about reverse split cams, intake restrictions and so on

After presenting the results and theories to Richard@wcch , he seems to agree and is interested in seeing the results

Only one way to know for sure though, I should have track times and dyno graphs

to compare the 2 soon

I'll post results reguardless if its good or bad

#4

Interesting....and WAAAAAAY different from what I went through to put an LS1 intake on mine:

* My injectors dropped right in....with the exception of the height difference. my LS1 intake was a '98 though so later LS6's might be different

* Manifold bolts were the same for both

* MY LS1 intake had the PCV nipple already installed from the factory

* TB cleared the WP housing without grinding

* Cutting down the truck WP outlet to 3/4" tall and putting an elbow in worked for me

Nice write-up though....VERY informative

* My injectors dropped right in....with the exception of the height difference. my LS1 intake was a '98 though so later LS6's might be different

* Manifold bolts were the same for both

* MY LS1 intake had the PCV nipple already installed from the factory

* TB cleared the WP housing without grinding

* Cutting down the truck WP outlet to 3/4" tall and putting an elbow in worked for me

Nice write-up though....VERY informative

#6

Thread Starter

TECH Fanatic

iTrader: (3)

Joined: Oct 2003

Posts: 1,612

Likes: 0

From: Winston Salem NC

Originally Posted by Yelo

Interesting....and WAAAAAAY different from what I went through to put an LS1 intake on mine:

* My injectors dropped right in....with the exception of the height difference. my LS1 intake was a '98 though so later LS6's might be different

* Manifold bolts were the same for both

* MY LS1 intake had the PCV nipple already installed from the factory

* TB cleared the WP housing without grinding

* Cutting down the truck WP outlet to 3/4" tall and putting an elbow in worked for me

Nice write-up though....VERY informative

* My injectors dropped right in....with the exception of the height difference. my LS1 intake was a '98 though so later LS6's might be different

* Manifold bolts were the same for both

* MY LS1 intake had the PCV nipple already installed from the factory

* TB cleared the WP housing without grinding

* Cutting down the truck WP outlet to 3/4" tall and putting an elbow in worked for me

Nice write-up though....VERY informative

thanks for chiming in

I take yours is cable driven from your previous posts

and what you've told me through PMs

Thats why I included that part about the cable driven TBs

but unfortunately this doesnt work with the DBW's

Thats crazy that its that much difference between the ls1 and ls6,

especially the bolts

The fitting I threaded in goes to the pass. side valve cover vent

From the best I can tell,

The car had this on the TB where the trucks' is attached to the intake

#7

Thread Starter

TECH Fanatic

iTrader: (3)

Joined: Oct 2003

Posts: 1,612

Likes: 0

From: Winston Salem NC

Originally Posted by BenKey

Good write-up. Getting ready to do a FAST intake myself. Can you take a better pic of what you do with the EVAP cannister? It's blocked in the pic.

was take the connector off the hard line from the PCV

clamped it to the stub that had the oring on it

then reduced it with

and let it feed into the brass nip on the front and driver side of the intake

Ill try to get a better pic of it

I may be going with a fbod type canister soon to clean things up a bit

here it is

Trending Topics

#9

Great post Kano!

Everything looks real nice too. I like your belt routing better than the speartech way. Are you using a stock length belt? Do you have any sketches for the idler bracket and fuel rail adapters? Also what did you do with that massive wire loom that goes over the top of the truck intake?

Can't wait for the results.

Everything looks real nice too. I like your belt routing better than the speartech way. Are you using a stock length belt? Do you have any sketches for the idler bracket and fuel rail adapters? Also what did you do with that massive wire loom that goes over the top of the truck intake?

Can't wait for the results.

#10

Thread Starter

TECH Fanatic

iTrader: (3)

Joined: Oct 2003

Posts: 1,612

Likes: 0

From: Winston Salem NC

Originally Posted by 02sierraz71_5.3

Glad to see you got everything fabed up and on the truck, count me in for dyno/track day.

I hope I can make my first run at nam

here pretty soon

still waiting on the WP spacer ring and pulley

to get back

Im going to order another pulley and stock make my own spacers

tomorrow

Its been over 2 weeks now and Im tired of waiting

Ill let ya know when she 's ready to roll