V-band Clamps

#11

If you have stainless headers, Y use v bands.. Stainless will not rust together like mild steel will, with slip fit header, that fits well into the Y stainless T clamps will hold it like a charm, not leak.. All you have to do is cut 3 small slots in the Y pipe slip ends, so they will seal tight around the collectors..

#15

sorry i didnt read the whole thread..

with my lpps, the y was a great fit besides one joint..i threw some copper RTV around it and then i just used band clamps..they are just a flat piece of sheet metal with bolts on the ends..they form to the joints and seal great..i got them for 9 a piece local...havent had a leak and have had the headers on for almost 2 months..

with my lpps, the y was a great fit besides one joint..i threw some copper RTV around it and then i just used band clamps..they are just a flat piece of sheet metal with bolts on the ends..they form to the joints and seal great..i got them for 9 a piece local...havent had a leak and have had the headers on for almost 2 months..

#17

Baltimore Whore

iTrader: (95)

Joined: Apr 2004

Posts: 16,820

Likes: 2

From: In a van DOWN BY THE RIVER

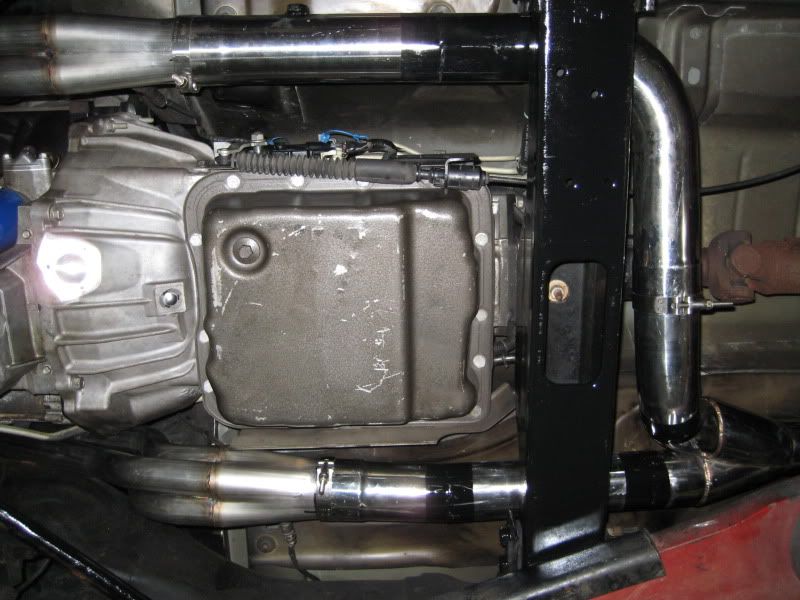

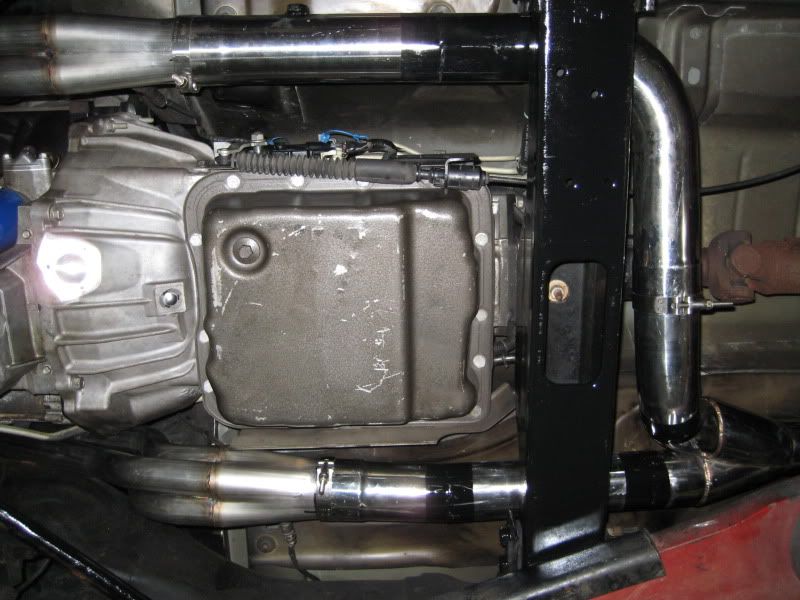

Here is the Y pipe I made.. It uses T clamps, the method I said. I have had them off a few times, never 1 issue. I also live where it rains, snows ect.. It is all the prep, fitment of the Y to the collectors that make slip fit stuff work.. If you half *** it it will half *** you.. just saying

#18

on that note, when i decided today that im rebuilding the 6.0 next summer, the first thing i thought of was how much of a pain it will be to take the headers and y off haha

#19

Yeah i think its just one slip fit on the lpp headers that sucks. The one connecting the driver side header to the y pipe is the worst on mine and my friends truck. It is super tight and we spend probably close to an hour trying to get it off everytime. Also, with the slip fits and lpp headers you always need to pull the trans crossmember to get the y pipe off. Never have to worry about that with vbands.