Building a SBC

#11

Launching!

Thread Starter

Join Date: Jun 2008

Location: Arizona

Posts: 286

Likes: 0

Received 0 Likes

on

0 Posts

I just printed out the wiring ECM schematics for a 2002 G Van 5.7L(0411 PCM) and the PCM harness schematics for my 2004 Silverado 4.3L.

Every single pin is identical between the two computers. The V6 PCM has blank pins where the V8 has the two extra injectors. And where the V8 has EGR pins the V6 is blank... however, even thought the V6 & V8 have injectors in the same pins. They are not the same cylinders, I have a feeling that has to do with firing order.

So we'll see, I'll try my current PCM re-wired and re-tuned.... if it doesn't work I'll snag a 0411 PCM.

Every single pin is identical between the two computers. The V6 PCM has blank pins where the V8 has the two extra injectors. And where the V8 has EGR pins the V6 is blank... however, even thought the V6 & V8 have injectors in the same pins. They are not the same cylinders, I have a feeling that has to do with firing order.

So we'll see, I'll try my current PCM re-wired and re-tuned.... if it doesn't work I'll snag a 0411 PCM.

#12

Launching!

Thread Starter

Join Date: Jun 2008

Location: Arizona

Posts: 286

Likes: 0

Received 0 Likes

on

0 Posts

Craigslist is great for an engine builder.

Last night a buddy and and I drove down to Phoenix from Prescott (in the worst rain storm) He bought a non-running 1995 Eagle Talon, lol. and I figured I'd find something for myself while we're going down there.

I found a dude who had an entire ZZ4 rotating assembly for cheap!

Forged Crank, Rods, Pistons, Dampener, Flex Plate, Timing Chain Cover, Valve Covers, ZZ4 roller cam, roller rockers all for about the price of a generic Pistons, gaskets, oil pump & freeze plugs rebuild kit.... so score!

Last night a buddy and and I drove down to Phoenix from Prescott (in the worst rain storm) He bought a non-running 1995 Eagle Talon, lol. and I figured I'd find something for myself while we're going down there.

I found a dude who had an entire ZZ4 rotating assembly for cheap!

Forged Crank, Rods, Pistons, Dampener, Flex Plate, Timing Chain Cover, Valve Covers, ZZ4 roller cam, roller rockers all for about the price of a generic Pistons, gaskets, oil pump & freeze plugs rebuild kit.... so score!

#13

TECH Junkie

Great build for a driver. SBC is still alive and well and cheap!

#14

Launching!

Thread Starter

Join Date: Jun 2008

Location: Arizona

Posts: 286

Likes: 0

Received 0 Likes

on

0 Posts

Made a EGR block off plate today.

Dropped off the ZZ4 parts at my shop. The part number on the cam is actually a GM Performance parts LT4 hot cam. But I'm not sure if I can trust it. The part number on the rocker arm box is for GM Performance 1.6 roller rollers but has stamped steel stockers inside. So I'll put a mic on the cam lobes and see if the lift is matches a LT4 cam or ZZ4 cam.

Going out of state for a week, I'll pick up where I left off when I get back.

Cheers ~Mykk

Dropped off the ZZ4 parts at my shop. The part number on the cam is actually a GM Performance parts LT4 hot cam. But I'm not sure if I can trust it. The part number on the rocker arm box is for GM Performance 1.6 roller rollers but has stamped steel stockers inside. So I'll put a mic on the cam lobes and see if the lift is matches a LT4 cam or ZZ4 cam.

Going out of state for a week, I'll pick up where I left off when I get back.

Cheers ~Mykk

Last edited by 04SilveradoMykk; 07-12-2008 at 11:52 PM.

#15

Launching!

Thread Starter

Join Date: Jun 2008

Location: Arizona

Posts: 286

Likes: 0

Received 0 Likes

on

0 Posts

Update:

The block is out getting Vat & Mag'd and Honed to the H345NCP-40 pistons. The entire rotating assembly is getting balanced, I decided to balance using the much smaller & lighter 4.3L v6 dampener and the v6 flexplate. A 2800-3000 stall locking converter is on order for the 4L60E currently in the truck.

Bead blasted the heads and drilled the pushrod holes out to 1/2" to accommodate the relocated pushrods due to 1.6 rockers , the heads are currently out getting bowl hawged. Once they get back I'll pin the studs, finish the gasket matching and polish the combustion chamber & exhaust port.

The Comp Beehive springs, retainers & locks have all arrived. As well as the summit quiet geardrive for roller cams. The proform 1.6 roller rockers have arrived as well.

On order, arriving today are Hooker 2462 long tube headers. Also on order, GMPP roller lifters, retainers & cage, cam locking plate, and Comp Hi-Tech pushrods.

While the major engine components are out getting machined I figured i'd start the intake manifold side of the gasket matching.

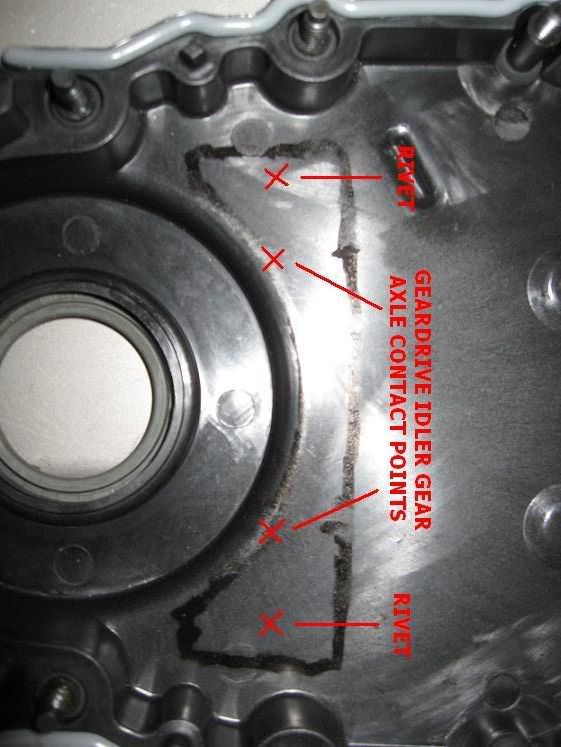

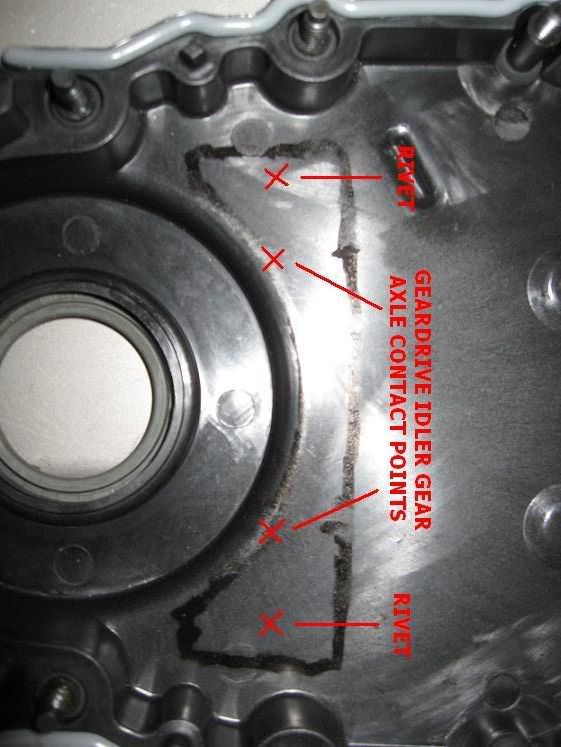

While mocking up the crank in the block and measuring all of the different depths, clearances, and gears involved in the geardrive. I discovered the crankshaft position sensor reluctor wheel would interfere with the geardrive idler gears.

My solution was to take a couple valve spring shims notched for the crank keyway and space the reluctor wheel from the crank timing gear by .120" that would give the clearance necessary for the idler gears to rely on the timing cover to keep from excessively walking into the reluctor wheel. I do intend to re-enforce the plastic vortec timing cover with a small stainless steel sheild riveted to the inside of the cover.

Cheers ~Mykk

The block is out getting Vat & Mag'd and Honed to the H345NCP-40 pistons. The entire rotating assembly is getting balanced, I decided to balance using the much smaller & lighter 4.3L v6 dampener and the v6 flexplate. A 2800-3000 stall locking converter is on order for the 4L60E currently in the truck.

Bead blasted the heads and drilled the pushrod holes out to 1/2" to accommodate the relocated pushrods due to 1.6 rockers , the heads are currently out getting bowl hawged. Once they get back I'll pin the studs, finish the gasket matching and polish the combustion chamber & exhaust port.

The Comp Beehive springs, retainers & locks have all arrived. As well as the summit quiet geardrive for roller cams. The proform 1.6 roller rockers have arrived as well.

On order, arriving today are Hooker 2462 long tube headers. Also on order, GMPP roller lifters, retainers & cage, cam locking plate, and Comp Hi-Tech pushrods.

While the major engine components are out getting machined I figured i'd start the intake manifold side of the gasket matching.

While mocking up the crank in the block and measuring all of the different depths, clearances, and gears involved in the geardrive. I discovered the crankshaft position sensor reluctor wheel would interfere with the geardrive idler gears.

My solution was to take a couple valve spring shims notched for the crank keyway and space the reluctor wheel from the crank timing gear by .120" that would give the clearance necessary for the idler gears to rely on the timing cover to keep from excessively walking into the reluctor wheel. I do intend to re-enforce the plastic vortec timing cover with a small stainless steel sheild riveted to the inside of the cover.

Cheers ~Mykk

Last edited by 04SilveradoMykk; 08-06-2008 at 11:09 AM.

#16

Launching!

Thread Starter

Join Date: Jun 2008

Location: Arizona

Posts: 286

Likes: 0

Received 0 Likes

on

0 Posts

The block, crank, pistons & rods, balancer & flexplate just came back from the balancer.

The block turned out great, the scuff mark in cyl # 5 from the previously exploded piston came out. And of course, I imediately painted the block as soon as it was back in my shop.

According to the balancer, the crank was in desperate need of some weight transfer. But now it's good to 7500rpm. I don't intend to go above 5800

The block turned out great, the scuff mark in cyl # 5 from the previously exploded piston came out. And of course, I imediately painted the block as soon as it was back in my shop.

According to the balancer, the crank was in desperate need of some weight transfer. But now it's good to 7500rpm. I don't intend to go above 5800

#20

Launching!

Thread Starter

Join Date: Jun 2008

Location: Arizona

Posts: 286

Likes: 0

Received 0 Likes

on

0 Posts

Mocked the motor mounts with the headers. The passenger side cleared, close but no interference. The drivers side mount needed to be notched in the corner to clear the headers.

Looking forward to following the build and the results

Looking forward to following the build and the results