2004 Silverado: 4.3L to SBC swap

#21

Day 3. Sept 8th.

Just taking it easy and going slow. I have a few appointments today that are keeping me from completely dedicating myself to the truck today.

My hopes of just having the transmission mount slid forward and giving me the misaligned motor mounts were wrong. The trans was all the way back in the slot on the crossmember and I was about 1" from having the motor mount bolt holes line up.

So I went with the first idea that came to mind. Elongate the transmission crossmember hole even more so the entire rotating assembly can slide back enough to compensate for how far off the motor mounts were.

And it worked! The engine is now bolted down and sitting at the correct level.

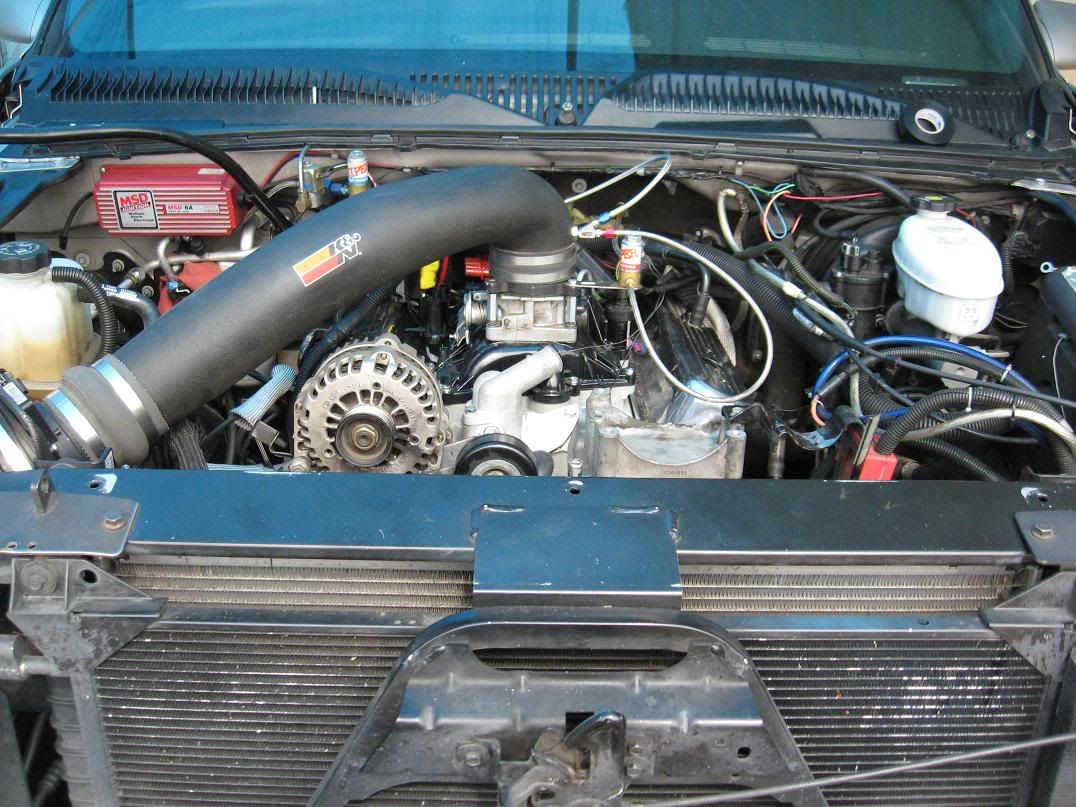

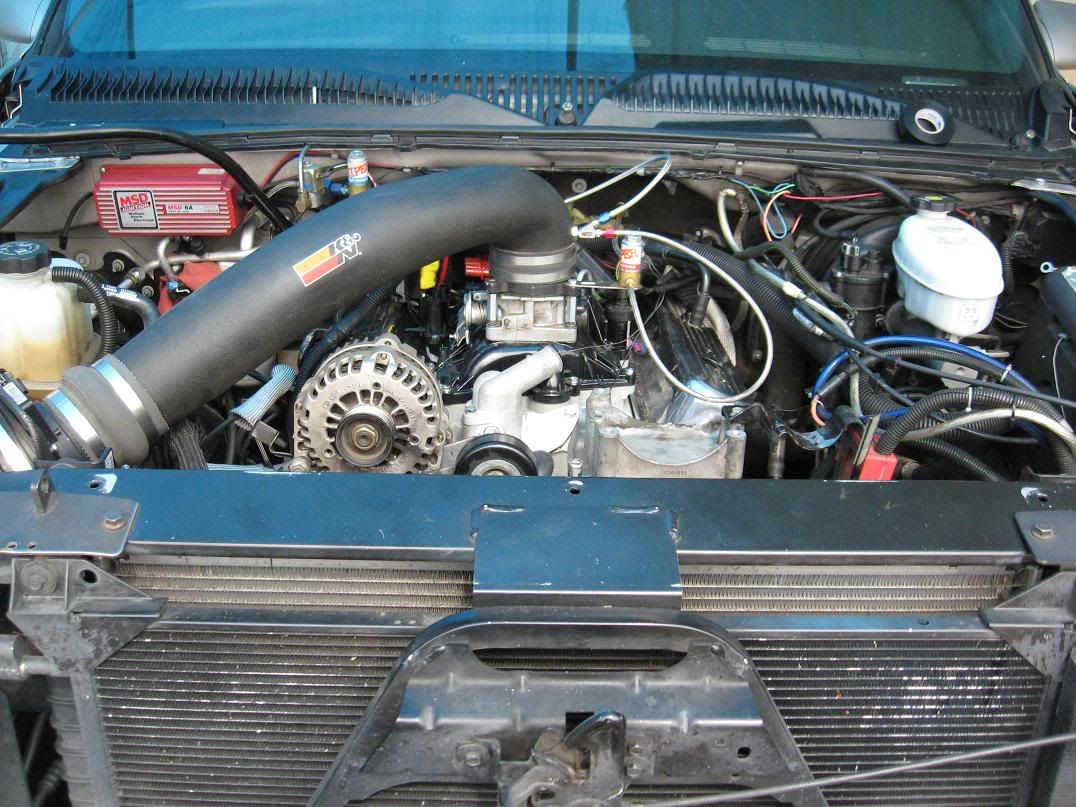

It's funny looking at the V8 with the 4.3L intake & TB & accessorys... it looks like I still have the six cylinder in there.

Check out all that room I still have too.

Cheers ~Mykk

Just taking it easy and going slow. I have a few appointments today that are keeping me from completely dedicating myself to the truck today.

My hopes of just having the transmission mount slid forward and giving me the misaligned motor mounts were wrong. The trans was all the way back in the slot on the crossmember and I was about 1" from having the motor mount bolt holes line up.

So I went with the first idea that came to mind. Elongate the transmission crossmember hole even more so the entire rotating assembly can slide back enough to compensate for how far off the motor mounts were.

And it worked! The engine is now bolted down and sitting at the correct level.

It's funny looking at the V8 with the 4.3L intake & TB & accessorys... it looks like I still have the six cylinder in there.

Check out all that room I still have too.

Cheers ~Mykk

#24

Day 4: Sept 09.

I only had a couple of hours to work on the truck today. When my shift ended at my job tonight I rushed over to work on the truck with the intention to get as much done as possible, work all night if I had to. But I'm afraid mother nature had other plans, it was clear all day today untill I got to the truck and it began to storm, hard! Even though I am working under cover the ground under the truck floods quickly and the winds just about tear the make shift "Tarp Garage" apart.

While I was working, I did notice a few problems.

1) The driveshaft does seem to be binding. The yoke is pressed all the way in to the trans tail housing. I'll pull the driveshaft tomorrow to have it shortened & balanced, a local shop here does that for about $100.00

2) Because the engine is back a bit from an OE location, I can't get the trans dipstick tube back into place. So I'll be looking into an aftermarket piece, like a Lokar flexable.

3) With the engine mated to the trans, the flexplate is pushed right up onto the torque converter. And it's tight, so tight I can't spin either the torque converter or the engine over by hand I must not have the torque converter in all the way. While I have the driveshaft out I'll seperate the engine & trans a bit to see if I can't get the TC to slip in another click.

I'm beginning to think I should have used the adapter plates that had the LSx mounts & SBC mounts 1" away from each other, if I had I would run into major header & motor mount interference issues. Oh well, The majority of the weight behind the front wheels equals better weight distribution.. right?

Once it got dark and the ground became flooded I switched to the topside of the engine and finished up the wiring of the V8 fuel injector harness as well as lengthened the A/C high pressure sensor leads. Pulled the temp sender harness out of the loom a bit, made new heater hoses and a crankcase air supply hose.

The old 4.3L throttle cable bracket will not work on the L31 intake manifold. GM needed to order the new bracket and I didn't want to wait, so instead I bent and modified the 4.3L bracket to bolt on to the V8 intake manifold. Seems to be working thus far.

Hopefully tomorrow will prove to more prosperous. I don't work at the job tomorrow.

This swap is taking a bit longer than I had hoped for, but I also knew I'd run into a few unforseen problems doing a swap like this.

Cheers ~Mykk

I only had a couple of hours to work on the truck today. When my shift ended at my job tonight I rushed over to work on the truck with the intention to get as much done as possible, work all night if I had to. But I'm afraid mother nature had other plans, it was clear all day today untill I got to the truck and it began to storm, hard! Even though I am working under cover the ground under the truck floods quickly and the winds just about tear the make shift "Tarp Garage" apart.

While I was working, I did notice a few problems.

1) The driveshaft does seem to be binding. The yoke is pressed all the way in to the trans tail housing. I'll pull the driveshaft tomorrow to have it shortened & balanced, a local shop here does that for about $100.00

2) Because the engine is back a bit from an OE location, I can't get the trans dipstick tube back into place. So I'll be looking into an aftermarket piece, like a Lokar flexable.

3) With the engine mated to the trans, the flexplate is pushed right up onto the torque converter. And it's tight, so tight I can't spin either the torque converter or the engine over by hand I must not have the torque converter in all the way. While I have the driveshaft out I'll seperate the engine & trans a bit to see if I can't get the TC to slip in another click.

I'm beginning to think I should have used the adapter plates that had the LSx mounts & SBC mounts 1" away from each other, if I had I would run into major header & motor mount interference issues. Oh well, The majority of the weight behind the front wheels equals better weight distribution.. right?

Once it got dark and the ground became flooded I switched to the topside of the engine and finished up the wiring of the V8 fuel injector harness as well as lengthened the A/C high pressure sensor leads. Pulled the temp sender harness out of the loom a bit, made new heater hoses and a crankcase air supply hose.

The old 4.3L throttle cable bracket will not work on the L31 intake manifold. GM needed to order the new bracket and I didn't want to wait, so instead I bent and modified the 4.3L bracket to bolt on to the V8 intake manifold. Seems to be working thus far.

Hopefully tomorrow will prove to more prosperous. I don't work at the job tomorrow.

This swap is taking a bit longer than I had hoped for, but I also knew I'd run into a few unforseen problems doing a swap like this.

Cheers ~Mykk

#25

Sounds like the normal kind of issues that you'd run into with this kind of swap, hopefully they can be remedied easily and painlessly.

Will that intake tube clear the hood, it looks kinda high from the pics?

Moving right along...

Will that intake tube clear the hood, it looks kinda high from the pics?

Moving right along...

#26

Day 5, Sept 10th

Just taking a break, figured I'd post up todays progress while putting my feet up for a sec.

After talking to the shop that would do the driveshaft work for me, we agreed that based on the location of the yoke in the tailshaft we would not need to cut down the driveshaft... that was a relief.

I separated the trans from the engine to see if I couldn't get the torque converter to seat down another click, so far I haven't been able to make it move in anymore. But my buddy with much smaller hands will give it a shot this eve when he gets home from work. I only hope I didn't hurt the pump.

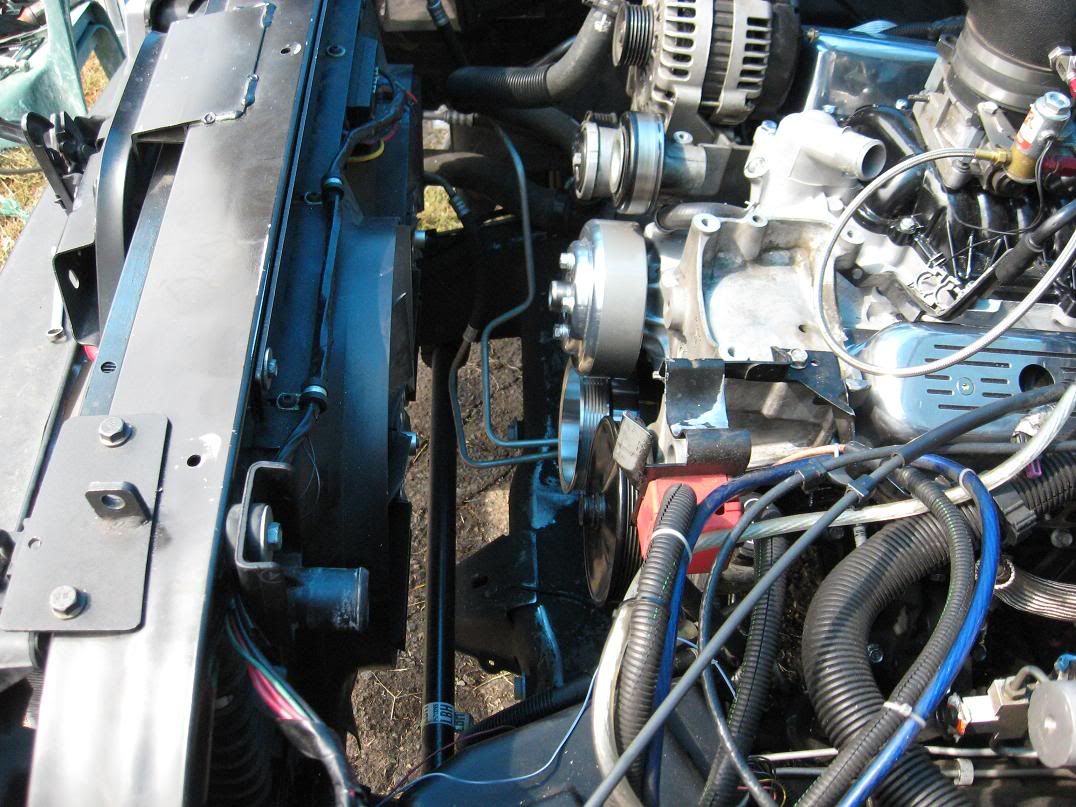

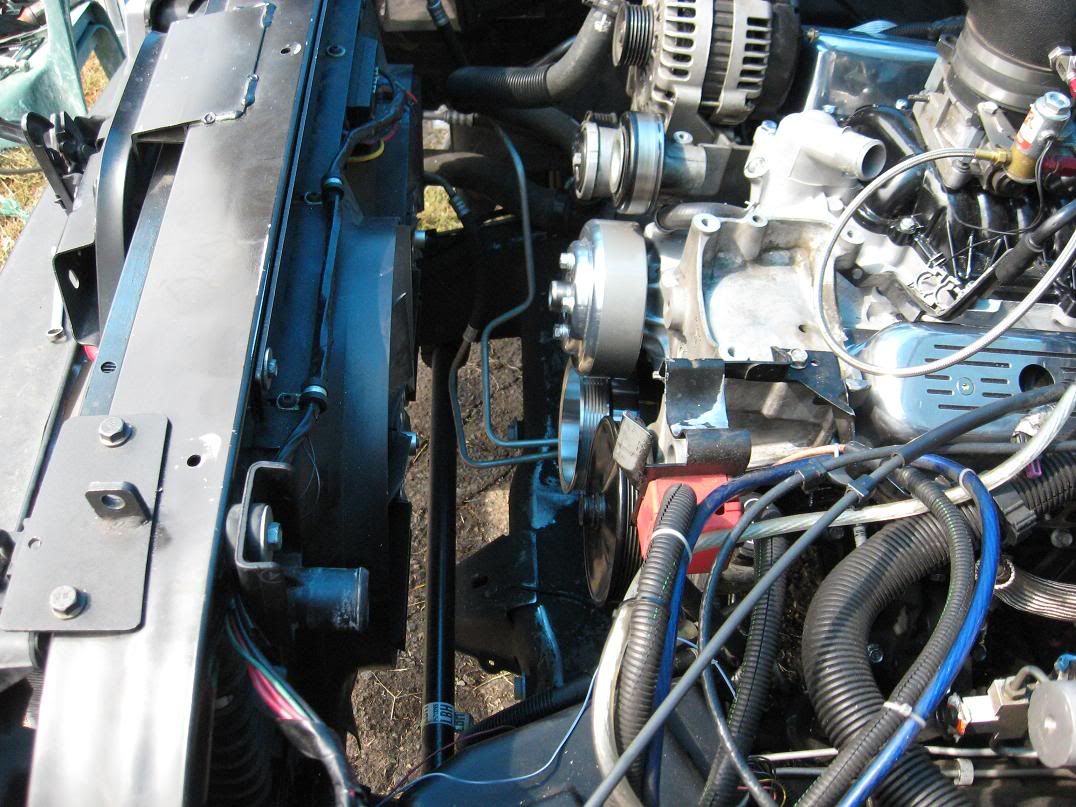

I put the A/C system back together, and wrapped up the cooling system. I ended up lifting the A/C compressor a hair higher and needed to go get a new serp belt.

The headers are a success, sort of. The drivers side sneaks in and clears the steering shaft.

the passenger side, however, fits just fine on the engine side and clears the frame... but the header does hit on the bottom corner of the cab and prevents from putting in the header bolts. I wasn't going to let that stop me, out came the cutting wheel to make clearance for the header.

I'll pick back up again in a few minutes.

Cheers ~Mykk

Just taking a break, figured I'd post up todays progress while putting my feet up for a sec.

After talking to the shop that would do the driveshaft work for me, we agreed that based on the location of the yoke in the tailshaft we would not need to cut down the driveshaft... that was a relief.

I separated the trans from the engine to see if I couldn't get the torque converter to seat down another click, so far I haven't been able to make it move in anymore. But my buddy with much smaller hands will give it a shot this eve when he gets home from work. I only hope I didn't hurt the pump.

I put the A/C system back together, and wrapped up the cooling system. I ended up lifting the A/C compressor a hair higher and needed to go get a new serp belt.

The headers are a success, sort of. The drivers side sneaks in and clears the steering shaft.

the passenger side, however, fits just fine on the engine side and clears the frame... but the header does hit on the bottom corner of the cab and prevents from putting in the header bolts. I wasn't going to let that stop me, out came the cutting wheel to make clearance for the header.

I'll pick back up again in a few minutes.

Cheers ~Mykk

#27

Ran into a major dilemma. The torque converter doesn't fit.

The snout on the 3000 stall TC has a beveled edge that goes into the end of the crankshaft. That snout is far too long, the crank bottoms out on the snout before the engine can bolt up to the transmission... and if you try to force the bell housing bolts to close the gap the TC gets pinched between the engine adn the trans and the entire rotating assembly siezes.

I'm not sure what my solution is yet, I'll call the TC manufacturer tomorrow. I could very well just have a defect TC and just either need to replace it or have them machine that surface to the right dimensions. Either way it's set me back and is the last thing on this engine swap, I have a feeling I won't make it to the cruisin carshows this weekend.

Cheers ~Mykk

The snout on the 3000 stall TC has a beveled edge that goes into the end of the crankshaft. That snout is far too long, the crank bottoms out on the snout before the engine can bolt up to the transmission... and if you try to force the bell housing bolts to close the gap the TC gets pinched between the engine adn the trans and the entire rotating assembly siezes.

I'm not sure what my solution is yet, I'll call the TC manufacturer tomorrow. I could very well just have a defect TC and just either need to replace it or have them machine that surface to the right dimensions. Either way it's set me back and is the last thing on this engine swap, I have a feeling I won't make it to the cruisin carshows this weekend.

Cheers ~Mykk

#29

Here is the story on the torque converter:

I just got off the phone with the manufacturer... (Backstory: I had the 350 crank & rods balanced with a 2004 4.3L flexplate and dampener and ordered the TC for a 2004 Silverado 4L60E 4.3L) according to the manufacturer the torque converter is correct for my application; 2004 Silverado 4l60E with a 4.3L. However I am running into a problem because the end of the crank on a modern 4.3L is different from a L31 350. At least that is what he told me. If indeed that is the case, it goes to show that a 350 is not a direct swap for the 4.3L in NBS trucks

I'll be putting my micrometer on both crank ends to compare them. I'll also mic both pilot snouts on the stock converter and the aftermarket.

The company is building me another torque converter with a roughly 1/8" shorter pilot snout and will trade me out for the other converter.

I do not know how far out it will be before I recieve the new converter

Cheers ~Mykk

I just got off the phone with the manufacturer... (Backstory: I had the 350 crank & rods balanced with a 2004 4.3L flexplate and dampener and ordered the TC for a 2004 Silverado 4L60E 4.3L) according to the manufacturer the torque converter is correct for my application; 2004 Silverado 4l60E with a 4.3L. However I am running into a problem because the end of the crank on a modern 4.3L is different from a L31 350. At least that is what he told me. If indeed that is the case, it goes to show that a 350 is not a direct swap for the 4.3L in NBS trucks

I'll be putting my micrometer on both crank ends to compare them. I'll also mic both pilot snouts on the stock converter and the aftermarket.

The company is building me another torque converter with a roughly 1/8" shorter pilot snout and will trade me out for the other converter.

I do not know how far out it will be before I recieve the new converter

Cheers ~Mykk

#30

After waiting, and waiting, and waiting some more the new TC finally arrived.

That day I got the TC stabbed in the trans, bolted the trans to the engine, TC to Flex, headers, and finished up every other nut & bolt and put the truck back on the ground.

At first test fire, there was no fire. I plugged in my laptop and used HPTuners scanner to see that TPS was at 98% at idle and wasn't reacting to my right root. It turned out I had the TPS harness plugged into the A/C highside sensor. So I put the right harness in the right sensor and tried again, it wanted to fire up but popped, spit & sputtered... I must have the timing way out.

And this is what the CPS looks like after getting up close and personal to the firewall.

so I robbed the CPS from the V6

That was it, I had run out of time to complete the swap. My days off were over, I needed to return back to work. And my friend (who let me do the swap at his place) was getting anxious to get the vehicle out of there.

In the name of getting my truck running I had the truck towed to my friends shop were he will set the dist to a true 0 degree and make a new Y-pipe from the headers back.

We will also fix a newly found problem, one of the hardlines on the power steering rack was spewing PS fluid. (as seen in the photo getting loaded on the flatbed)

Cheers ~Mykk

That day I got the TC stabbed in the trans, bolted the trans to the engine, TC to Flex, headers, and finished up every other nut & bolt and put the truck back on the ground.

At first test fire, there was no fire. I plugged in my laptop and used HPTuners scanner to see that TPS was at 98% at idle and wasn't reacting to my right root. It turned out I had the TPS harness plugged into the A/C highside sensor. So I put the right harness in the right sensor and tried again, it wanted to fire up but popped, spit & sputtered... I must have the timing way out.

And this is what the CPS looks like after getting up close and personal to the firewall.

so I robbed the CPS from the V6

That was it, I had run out of time to complete the swap. My days off were over, I needed to return back to work. And my friend (who let me do the swap at his place) was getting anxious to get the vehicle out of there.

In the name of getting my truck running I had the truck towed to my friends shop were he will set the dist to a true 0 degree and make a new Y-pipe from the headers back.

We will also fix a newly found problem, one of the hardlines on the power steering rack was spewing PS fluid. (as seen in the photo getting loaded on the flatbed)

Cheers ~Mykk

Last edited by 04SilveradoMykk; 09-25-2008 at 08:37 AM.