BlackGMC build, suspension, fuel system, exhaust etc...

#22

Thread Starter

Resident Retard

iTrader: (31)

Joined: Jan 2006

Posts: 17,216

Likes: 20

From: Fort Worth - TX

#25

Thread Starter

Resident Retard

iTrader: (31)

Joined: Jan 2006

Posts: 17,216

Likes: 20

From: Fort Worth - TX

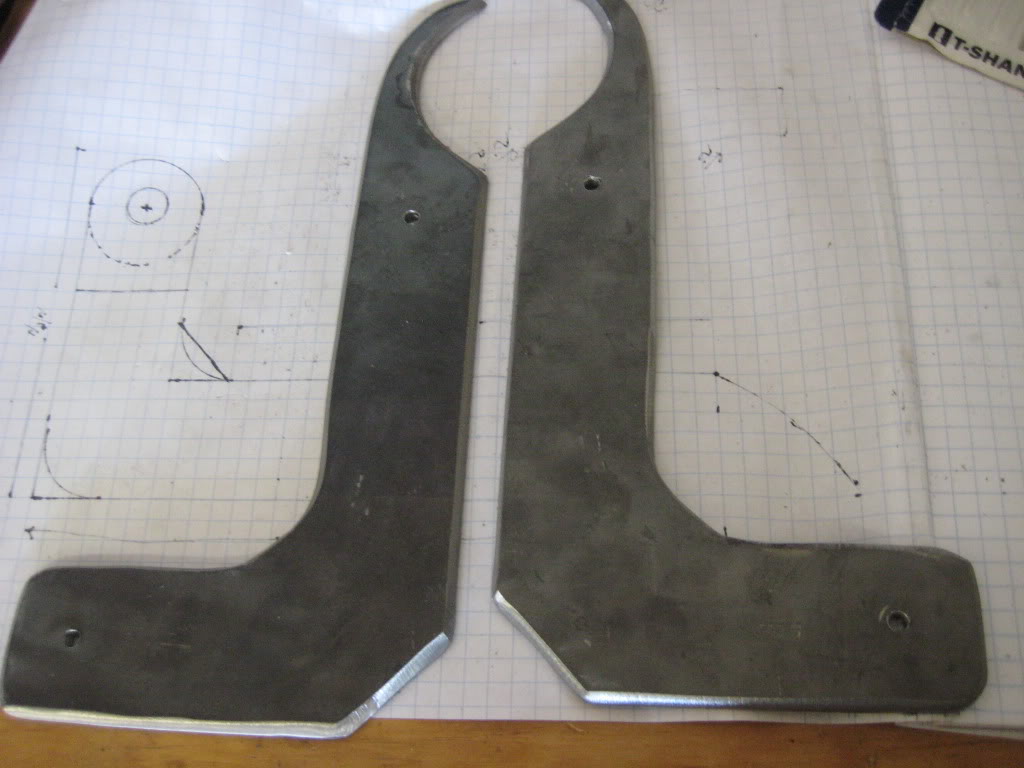

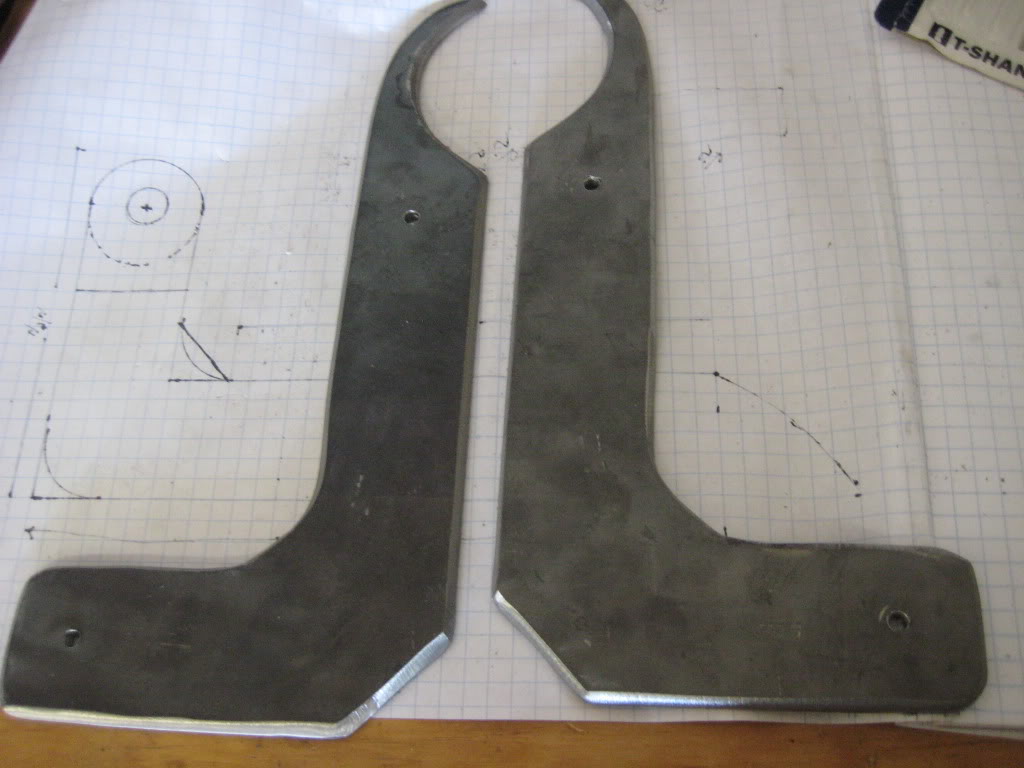

I made them  Below are the first ones i made, they ended up being too long, soo i had to remake them but i did not take pictures but they look like the below.

Below are the first ones i made, they ended up being too long, soo i had to remake them but i did not take pictures but they look like the below.

This is the jig i made to help align and hold the upper and lower mounts. It worked like a champ!

either LS3 topend or FI... I have not decided...

I love welding. I am not the best but i am decent... The guy that was helping the last few days, i was teaching him to weld for the first time... He actually did pretty good for his first time...

I wish i had a bender... I usually buy 90* bend and cut them to the angle i want... Usually i cut all the 90*s into 45* and piece everything together that way...

Below are the first ones i made, they ended up being too long, soo i had to remake them but i did not take pictures but they look like the below.

Below are the first ones i made, they ended up being too long, soo i had to remake them but i did not take pictures but they look like the below.

This is the jig i made to help align and hold the upper and lower mounts. It worked like a champ!

either LS3 topend or FI... I have not decided...

I wish i had a bender... I usually buy 90* bend and cut them to the angle i want... Usually i cut all the 90*s into 45* and piece everything together that way...

#26

ya it just seems like with a welder and some time and creativity the options are endless.

I have never touched a welder but a friend of mine was a welder on the USS Ronald Reagan for 5 years and just bought a welder for home so hoping I can learn one of these days. When I finally get my LT's and all that I will get a chance to learn and have him help me weld it all up.

What was your reason for doing true dual over a single??

I have never touched a welder but a friend of mine was a welder on the USS Ronald Reagan for 5 years and just bought a welder for home so hoping I can learn one of these days. When I finally get my LT's and all that I will get a chance to learn and have him help me weld it all up.

What was your reason for doing true dual over a single??

#28

Thread Starter

Resident Retard

iTrader: (31)

Joined: Jan 2006

Posts: 17,216

Likes: 20

From: Fort Worth - TX

Also on a side note, I did not adjust anything on my tune and the trims were still +/- 3%.... I left the IFR table the same, because i did not hook up the vacuum reference... After i swap out the exhaust and need to retune it I will hook up the vacuum reference line and adjust the IFR table for return style. I thought that was worth noting.

#29

Thread Starter

Resident Retard

iTrader: (31)

Joined: Jan 2006

Posts: 17,216

Likes: 20

From: Fort Worth - TX

ya it just seems like with a welder and some time and creativity the options are endless.

I have never touched a welder but a friend of mine was a welder on the USS Ronald Reagan for 5 years and just bought a welder for home so hoping I can learn one of these days. When I finally get my LT's and all that I will get a chance to learn and have him help me weld it all up.

What was your reason for doing true dual over a single??

I have never touched a welder but a friend of mine was a welder on the USS Ronald Reagan for 5 years and just bought a welder for home so hoping I can learn one of these days. When I finally get my LT's and all that I will get a chance to learn and have him help me weld it all up.

What was your reason for doing true dual over a single??

Learning to weld and owning a welder is great! Honestly i have no clue on what i would do if i did not have one... Metal is one of the easiest things to work with. I learned to weld working in an exhaust shop during college, and i also welded when i worked in a body shop... Actually this is my first time welding stuff this thick... 3/16 is the thickest i have tried to weld with this welder. It is a lincoln 175 (220 volt), it is not as nice as a miller but it works for me. Eventually a tig will be sitting next to it

About the dual 3inch, i dunno, just something different, plus i have all that room underneath, might as well use it right??