I can't fabricate?

#31

Hunt&Fisherator

iTrader: (15)

custm2500

10-09-2008, 08:14 PM

Shims are like 5 dollars for a 3degree. I don't need them I droped the axle level. I didn't get any pics took the kids to get and carve pumpkins.

- I don't even know where to begin here... I hope you've learned something since 2008. Dropping an axle "level" will change your pinion angle dramatically, the whole housing needs to rotate when you change the ride height from stock to maintain proper working angles of the shaft and U-joints. And hopefully you figured this out before you built this bulletproof 4 link setup you speak so highly of. If you want to get into a suspension debate, I'm all ears

10-09-2008, 08:14 PM

Shims are like 5 dollars for a 3degree. I don't need them I droped the axle level. I didn't get any pics took the kids to get and carve pumpkins.

- I don't even know where to begin here... I hope you've learned something since 2008. Dropping an axle "level" will change your pinion angle dramatically, the whole housing needs to rotate when you change the ride height from stock to maintain proper working angles of the shaft and U-joints. And hopefully you figured this out before you built this bulletproof 4 link setup you speak so highly of. If you want to get into a suspension debate, I'm all ears

#32

A generic 4 link kit will have infinite mounting points on a truck, car, or tube buggy. Therefore they sell kits, because there is a need. Two completely different concepts.

#33

Silver-mod-o

I am not searching through the thread to figure out why that post was made, but I did put shims to correct the pinion angle. I got them for free so I am really confused why i tallked about price and I obviously knew about pinon angle since I installed shims when I droped it.

I am not searching through the thread to figure out why that post was made, but I did put shims to correct the pinion angle. I got them for free so I am really confused why i tallked about price and I obviously knew about pinon angle since I installed shims when I droped it.

#35

Take it out of your truck and take it apart. That is all there is. I will post pics of the parts of my stock TB. I am not arguing the fact weather of not my TB will work. The fact is they are EXTREAMLY simple.

Please just wait till tomorrow and when I post pics of my stock TB you can tell me they are still complicated.

Again not debating the working or not working of my TB, the arguement is the simplicity VS. complexity of a TB.

Please just wait till tomorrow and when I post pics of my stock TB you can tell me they are still complicated.

Again not debating the working or not working of my TB, the arguement is the simplicity VS. complexity of a TB.

#37

No I don't lash out at everyone. I do loose my cool when people continue to talk about something they apparently don't have a clue about. I use constructive advice or concerns to learn and grow, but I get sick and tired of people who have probably not even taken a certain part of there truck, let alone dis-assembled it to see how simple or complex it is. That is where the raised temper comes from.

I don't go to someone on this forum and say your wife/daughter is fat and ugly, because I have never seen them. I also can't tell them if they are nice or mean again because it is something I have never experienced. So how can someone tell me the physical make up of something is more complex them I am telling them it is when I have one sitting on my tool box at work, torn apart.

I am not overly worked up and my stress level is cool so I don't really need a xanax(sp?). The point of this thread is prove to the people who try to **** on everything I do that I have produced some decent looking, properly functioning modifications to my truck. I don't expect to be regarded as top builder on the site, and I don't need validation from anyone on this site or any other. I just want to be able to use this forum to get and give advice without every thread turning into an argument over a "work in progress" photo from 6 months ago.

I don't go to someone on this forum and say your wife/daughter is fat and ugly, because I have never seen them. I also can't tell them if they are nice or mean again because it is something I have never experienced. So how can someone tell me the physical make up of something is more complex them I am telling them it is when I have one sitting on my tool box at work, torn apart.

I am not overly worked up and my stress level is cool so I don't really need a xanax(sp?). The point of this thread is prove to the people who try to **** on everything I do that I have produced some decent looking, properly functioning modifications to my truck. I don't expect to be regarded as top builder on the site, and I don't need validation from anyone on this site or any other. I just want to be able to use this forum to get and give advice without every thread turning into an argument over a "work in progress" photo from 6 months ago.

#38

TECH Regular

Two things, those are cold welds, and anyone who's done any amount can tell you didn't put much time into surface prep. They may hold, they may not. I wouldn't trust them.

#39

GFYS and STFU

iTrader: (8)

First off: 80% of welding is prep, prep and more prep. And I dare say that's where most of your problems lie when it comes to everything you do. You don't care about prep which is reflected in the final result of all your projects and THAT is why most people are ragging on you. The holes you cut in the frame (aside from being poorly thought out) were terrible because there was no prep. You just burned a hole in the frame and tried to weld something back in it. Had you gone to trade school of some sort, a good instructor/professor would have DRILLED it into your head the importance of prep in anything you do, especially welding.

Secondly: Those welds you showed are the result of not using the proper power settings resulting in poor penetration. Those will be the first things to break when that part is put under stress.

Just because you did something, doesn't mean it was done right. Kudo's for trying but your looking for a pat on the back just cuz you did it, won't happen on here because most are able to see that it wasn't done well.

That being said, for the power your making, those welds might hold, but they are the weak link in that set-up, and that is the complete opposite of what welding is. A weld is stronger than it's surrounding structure. Just FYI.

#40

GFYS and STFU

iTrader: (8)

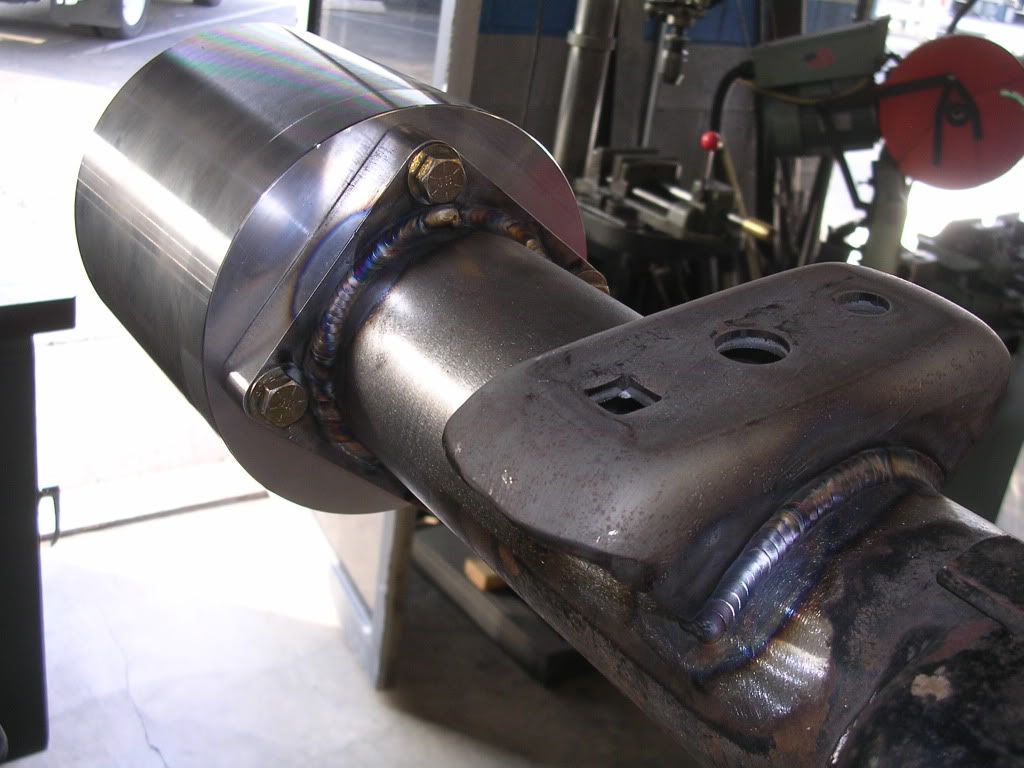

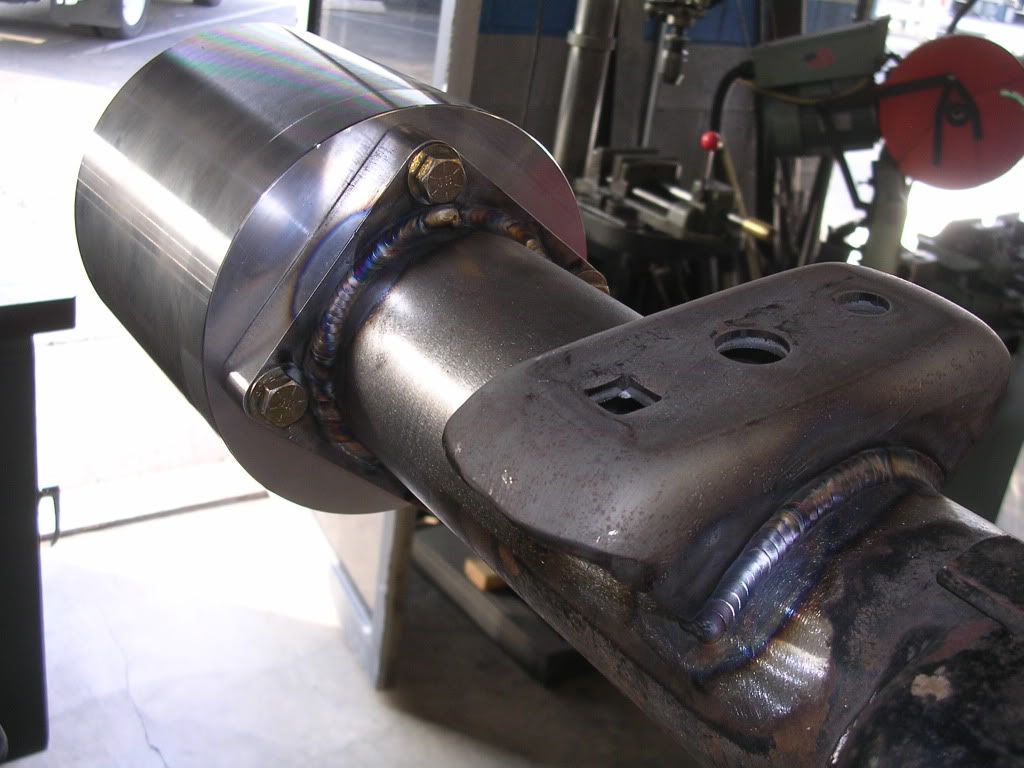

These pictures are from another members rear-end build...look at the prep that was done on the housing prior to welding, the speed, spacing and consistency of the bead and most importantly the penetration...

These welds are the result of proper prep, correct power settings and experience. Two of the three you can easily manage, the last is something you will gain over time.

This on the other hand, is lacking all three.

There is so little penetration you might as well used a soldering gun for the amount of good those welds are gonna do.

These welds are the result of proper prep, correct power settings and experience. Two of the three you can easily manage, the last is something you will gain over time.

This on the other hand, is lacking all three.

There is so little penetration you might as well used a soldering gun for the amount of good those welds are gonna do.