Somthing a lil diff for yall, my little project toy...

#12

Launching!

Thread Starter

Join Date: Apr 2007

Location: Dickinson,Tx

Posts: 225

Likes: 0

Received 0 Likes

on

0 Posts

57 Bel-Air

87 SS Mont Carlo Aero Coupe 1 of 2000 for that year

'05 Dodge SRT-4

And the Pos 67 Mustang out front that is my sisters Bf's

Lots of space, but runs out quick when you 4 projects inside there lol.

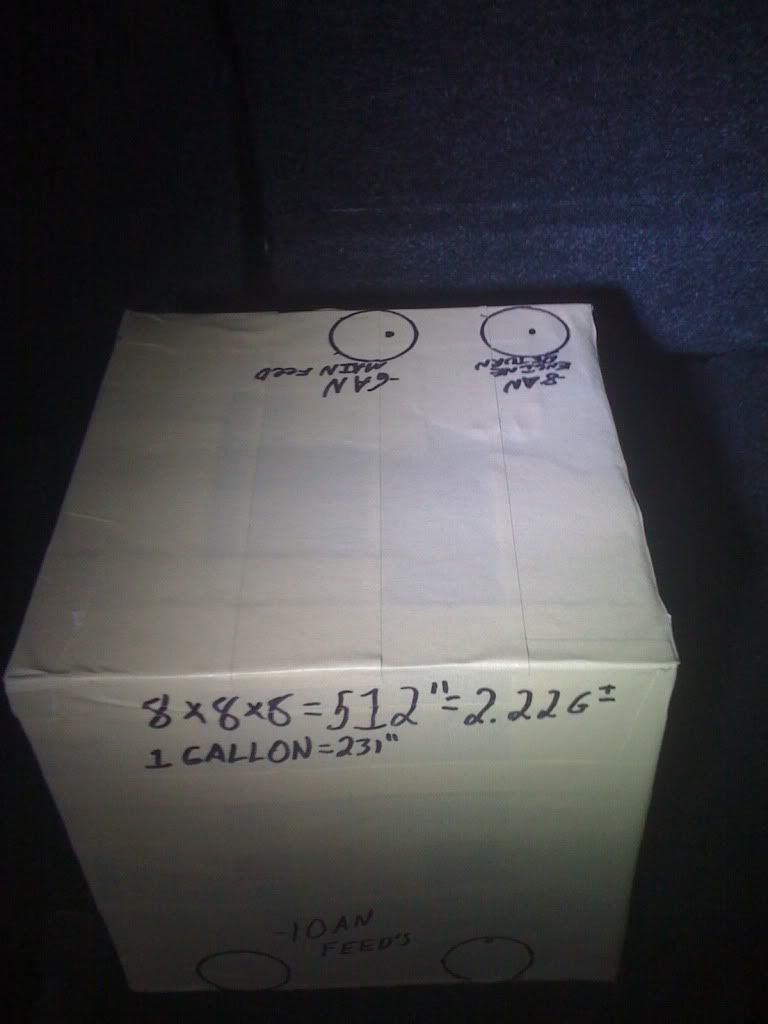

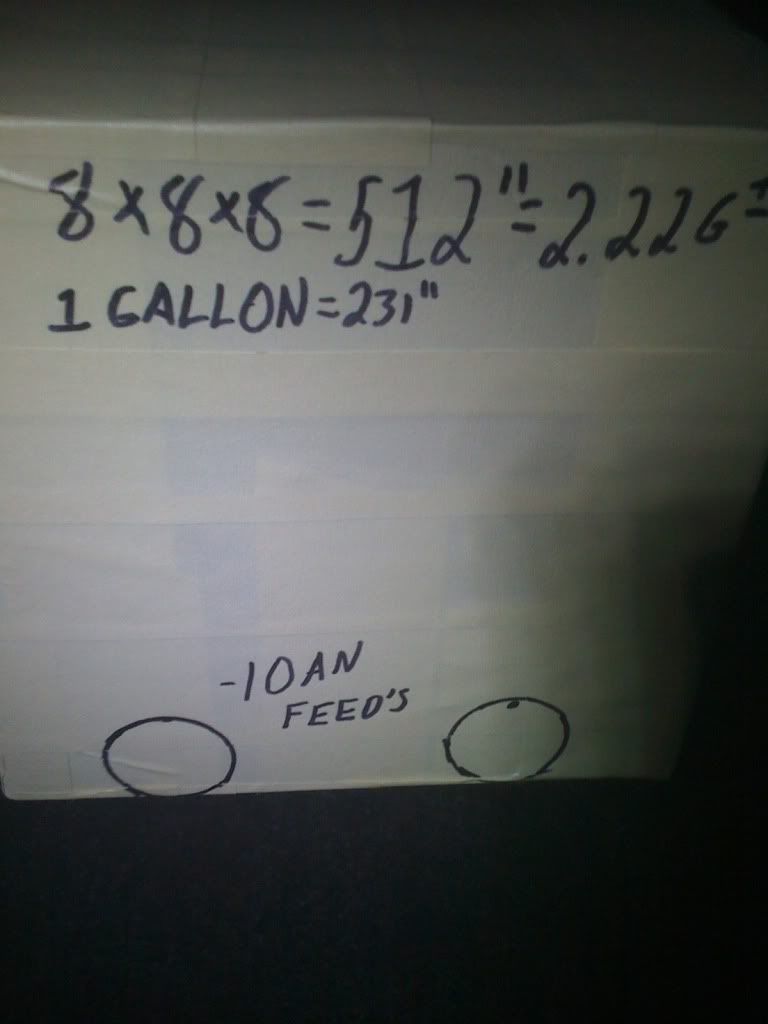

The block went to the machine shop Monday to get the machining and balancing done and also getting the block O-ringed for that extra protection when running 35-40lbs of boost. I have my surge tank bent and ready to be welded, but was to nasty today to pull out the gas welder.

Mock ups before i bent all the aluminum and still need to weld it.

Gear set is still apart, the reverse thrust washer seat area needs to be machined down a couple of thousandths. Figured this out after breaking a $50 washer.

its that seat just above the upper gear there.

Secret traction aides

6600LB working strength chain ( Took two of us, $150 bolt cutters that got ruined to cut this stuff at Tractor supply

), Grade 8 hardware and cold rolled steel bar. Super secret stuff here

), Grade 8 hardware and cold rolled steel bar. Super secret stuff hereAlso the Twin disk clutch and intercooler are on the way as well. Once i get the engine and tranny built and back in there ill be able to start fabbing up all the custom stuff. Intercooler piping and 4" exhaust. Maybe even a tubular manifold, haven't decided yet.

Lol. Progress will start moving again once I get the block back in a week or so. Sucks waiting on parts.

#15

Launching!

Thread Starter

Join Date: Apr 2007

Location: Dickinson,Tx

Posts: 225

Likes: 0

Received 0 Likes

on

0 Posts

Quartermaster/Rage Twin disk clutch

Intermediate/output shaft strip down to install rage first gear.

Going back together...

For yall truck guys, the diff on that first gear there and the first gear on my new billet input shaft is the stronger straight cut/ Dogbox gear. Its a longer first gear to rap the FWD drive out to get better use of traction etc. Dogbox trannies are used throughout the road racing world mostly, same with Nascar cup cars as well. They have no syncros so you dont have to clutch on the upshift, you have to slam it in. But if you don't do it right you will break one easier than the helical gears.

Here is a really good example, yes the scream is from the straight cut gears

http://www.youtube.com/watch?v=eSJ-HzNWJGM

Intermediate/output shaft strip down to install rage first gear.

Going back together...

For yall truck guys, the diff on that first gear there and the first gear on my new billet input shaft is the stronger straight cut/ Dogbox gear. Its a longer first gear to rap the FWD drive out to get better use of traction etc. Dogbox trannies are used throughout the road racing world mostly, same with Nascar cup cars as well. They have no syncros so you dont have to clutch on the upshift, you have to slam it in. But if you don't do it right you will break one easier than the helical gears.

Here is a really good example, yes the scream is from the straight cut gears

http://www.youtube.com/watch?v=eSJ-HzNWJGM

#16

Launching!

Thread Starter

Join Date: Apr 2007

Location: Dickinson,Tx

Posts: 225

Likes: 0

Received 0 Likes

on

0 Posts

Ok time for some updates, engine block is back from the machine shop, just waiting on Sonny to get his *** in line so he can be here to watch the engine build:hi:.

Engine block after painting:

Balance chain oil hole welded up:

Painted the cam gears to somewhat match my candy red valve cover:

Heat wrapped brake lines on the firewall, have some more wrapping to do as well, I don't want to die from the brakes not working when/if the turbo heat melts them, seen it happen before:

Here's some pics of the porting i did on some key components to live at high RPM's etc, get more oil to the bearings etc. And generally just so the oil flows way easier with lest restriction,rounded turns etc. I don't have a pic of the ported gallies in the oil pan, ill get one for y'all tomorrow or something:

Oil adapter:

PUMP:

Intake mani that I ported to gasket match and match my F&F race head (before final polishing):

So maybe tomorrow ill get to building the engine and make my windage tray. Gonna do some special crank modifications to help get more oil and better oil lubrication to the crank bearings that way i wont have any oiling problems at high RPM's.

Any questions ask away:hi:

Edit: polished crank and prepped block to assemble sunday and come to find out the main bearing thrust bearings tab isn't right for lining up on the groove of the block, so ill have to go swap the bearings out at the end of the week, vendor fault not mine.

Engine block after painting:

Balance chain oil hole welded up:

Painted the cam gears to somewhat match my candy red valve cover:

Heat wrapped brake lines on the firewall, have some more wrapping to do as well, I don't want to die from the brakes not working when/if the turbo heat melts them, seen it happen before:

Here's some pics of the porting i did on some key components to live at high RPM's etc, get more oil to the bearings etc. And generally just so the oil flows way easier with lest restriction,rounded turns etc. I don't have a pic of the ported gallies in the oil pan, ill get one for y'all tomorrow or something:

Oil adapter:

PUMP:

Intake mani that I ported to gasket match and match my F&F race head (before final polishing):

So maybe tomorrow ill get to building the engine and make my windage tray. Gonna do some special crank modifications to help get more oil and better oil lubrication to the crank bearings that way i wont have any oiling problems at high RPM's.

Any questions ask away:hi:

Edit: polished crank and prepped block to assemble sunday and come to find out the main bearing thrust bearings tab isn't right for lining up on the groove of the block, so ill have to go swap the bearings out at the end of the week, vendor fault not mine.

#18

Launching!

Thread Starter

Join Date: Apr 2007

Location: Dickinson,Tx

Posts: 225

Likes: 0

Received 0 Likes

on

0 Posts

Yes the bolts are spot welded,same as on the crank. Anything that is going to be in direct contact of the 8.5-9k Rpm range will either get spot welded with red locktight or like the flywheel bolts will get safety wired. I use safety wire on anything that is going to be under any sort of pressure as well.

Heres the crank polishing etc, and some of the oiling mods I was doing for the bearings. Yes I look young as fawk,no im not as young as i look

http://www.youtube.com/watch?v=me9pX...eature=recentu

#19

Launching!

Thread Starter

Join Date: Apr 2007

Location: Dickinson,Tx

Posts: 225

Likes: 0

Received 0 Likes

on

0 Posts

Small update.....

Got the short block built yesterday. Gonna finish the long block Thurs.

Finally getting things BACK together now. Also have about half of the fuel system plumbed from the main tank into the trunk. Transmission parts should be back from the machinist next week, hopefully.

Got the short block built yesterday. Gonna finish the long block Thurs.

Finally getting things BACK together now. Also have about half of the fuel system plumbed from the main tank into the trunk. Transmission parts should be back from the machinist next week, hopefully.

#20

Launching!

Thread Starter

Join Date: Apr 2007

Location: Dickinson,Tx

Posts: 225

Likes: 0

Received 0 Likes

on

0 Posts

Engine is now fully assembled, outside of all the little external do-dads.

ARP cam tower studs, these little ******* are expensive for what they are :stab:

:thumbsup:

As soon as my tranny stuff is finished i will be assembling it and everything will be going back in the car here pretty soon.:thumbsup::readclose

ARP cam tower studs, these little ******* are expensive for what they are :stab:

:thumbsup:

As soon as my tranny stuff is finished i will be assembling it and everything will be going back in the car here pretty soon.:thumbsup::readclose