Correct MetriPack pins for FUEL tank connector ?

#1

TECH Apprentice

Thread Starter

Getting ready to drop TANK under Suburban.

GMT800 , model year 2003

Plan to install new fuel pump, and would like to upgraydd WIRING to 12 gauge pump ground and Supply from fuse box to fuel tank HAT.

What are the correct MetriPack PINS to go in the truck connector ?

Can anyone confirm the harness end is Femal MetriPack 150 series ?

Any known source for pins in small lots ?

Think I can mash 12 gauge wire in the plastic housing ?

GMT800 , model year 2003

Plan to install new fuel pump, and would like to upgraydd WIRING to 12 gauge pump ground and Supply from fuse box to fuel tank HAT.

What are the correct MetriPack PINS to go in the truck connector ?

Can anyone confirm the harness end is Femal MetriPack 150 series ?

Any known source for pins in small lots ?

Think I can mash 12 gauge wire in the plastic housing ?

#2

Can anyone confirm the harness end is Femal MetriPack 150 series ?

https://www.aptiv.com/en/solutions/c...og?language=en

Any known source for pins in small lots ?

Think I can mash 12 gauge wire in the plastic housing ?

#3

If there is a concern about wire size fitting, use TXL type wire, it has the thinnest insulation jacket I think (and is still rated properly for engine bay/automotive use).

#4

TECH Apprentice

Thread Starter

AEM 340 lpm pump going in. Mild build, given best PUMP gasoline within 1100 Miles is 90 Octane Unleaded, Daily driver with 3.73 gears.

60 pound/hour injectors, so really mild build.

14 gauge wire seem adequate to Fuel Pump ?

factory appears to be metric equivalent near 16 gauge

60 pound/hour injectors, so really mild build.

14 gauge wire seem adequate to Fuel Pump ?

factory appears to be metric equivalent near 16 gauge

#5

factory appears to be metric equivalent near 16 gauge

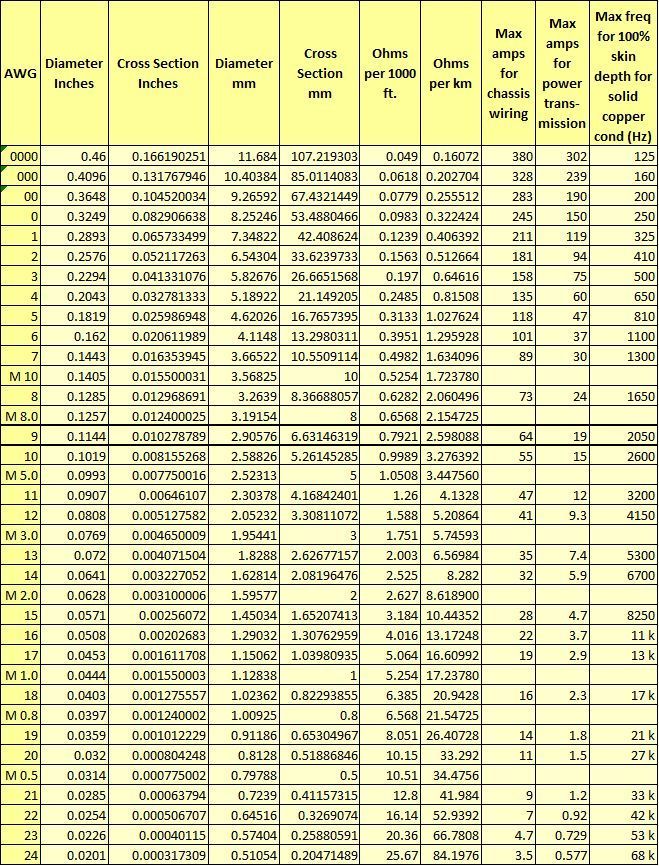

AWG sizes are logarithmic. Like audio decibels. A difference of 3 AWGs is almost an exact doubling of cross-sectional area (the sqrt of 10 to be exact, about 3.162, would be an exact doubling); 6 AWGs is a CSA multiple of about 4; 9 AWGs is a factor of near 8; 10 AWGs is a factor of almost exactly 10. Metric sizes are just convenient steps in the # of sq mm (also cross-sectional area), so, not nearly as mathematically consistent as AWG.

The largest terminals for MP150 connectors are for 1.0. Here's the part #s and sizes that are supported, from their catalog.

Part # Cable Range (mm2) Material Plating

12048074 1.0-0.80 Silicon Bronze Tin

12084200 0.50-0.35 Silicon Bronze Tin

12160223 1.0-0.80 Beryllium Copper Silver/Nickel

12160222 0.50-0.35 Beryllium Copper Silver/Nickel

Keep in mind this is the copper cross-sectional area, has nothing to do with the insulation. If the terminal barrel won't completely enclose the copper, or if the wire is so stiff that it either breaks the terminal or pulls out because the terminal can't contain it (imagine trying to use a hose clamp as an engine mount for a visual), it won't work, at least not for long. You can fake it somewhat by using wire with finer strands, and by soldering, butt only just so much. The insulation, in this matter, only matters as far as whether it will jam into the housing, and whether the little silicone seals can be forced over it.

What's the # printed on the wire?

Is it in fact a MP150 connector? If it's something else your options might be more open.

Last edited by RB04Av; 07-10-2024 at 02:59 PM.

#6

TECH Apprentice

Thread Starter

Well, I don't know for sure, looking at diagrams from net searches.

I have not drpped TANK yet, want to have my parts supply lined up.

Have a Coupla spools of red and black 12 gauge.

Plan to T in close to stock truck Fuel Pump relay with red wire, get it up close to fuel tank HAT, and if I have to, splice into existing wire TO fuel pump, or if it's crappy green and corroded, carefully remove the power and ground PINS from the connector, file them down bright N shiny, solder the new 12 gauge on the pins, and try to ram them back in the fuel tank connector, seal with permatex after install.

If it's all too rusted out, next option is to DRILL the fuel tanl HAT, poke some #10 Brass threaded rod through, double nut inside and out, run fuel pump wires internal, and POWER+ Ground wires external, fasten with brass 10-32 hex nuts, and paint it BLACK on the outside,..

IF I can source some Metripack Pins and stuff them into stock connector, It'll be cleaner and quicker.

I have not drpped TANK yet, want to have my parts supply lined up.

Have a Coupla spools of red and black 12 gauge.

Plan to T in close to stock truck Fuel Pump relay with red wire, get it up close to fuel tank HAT, and if I have to, splice into existing wire TO fuel pump, or if it's crappy green and corroded, carefully remove the power and ground PINS from the connector, file them down bright N shiny, solder the new 12 gauge on the pins, and try to ram them back in the fuel tank connector, seal with permatex after install.

If it's all too rusted out, next option is to DRILL the fuel tanl HAT, poke some #10 Brass threaded rod through, double nut inside and out, run fuel pump wires internal, and POWER+ Ground wires external, fasten with brass 10-32 hex nuts, and paint it BLACK on the outside,..

IF I can source some Metripack Pins and stuff them into stock connector, It'll be cleaner and quicker.

#7

There's about 3 or 4 connectors it COULD be... could be a MP150, could be a MP280, could be a "ASM Series" which I don't know what that is. L59 is different from LM7, can't tell from the FSM I have whether the 6.0 or 8.1 are different again. I'm kinda thinking it's more likely a MP280 which is a much larger part and accommodates larger wires butt I can't see up under your truck right now.

You can. Click on the Mouser link I posted.

If it's a MP280 then yes. If it's a 150 then no, you'll have to do the pigtail thing. No efffing way 12 gauge wire will go into that. No clue about it if you have the "AMS".

I think at the fuse/relay block end, you can solder a 12 gauge to the underside of the terminal, if you're real careful, and if your wire is something better than generic parts store "primary wire". That stuff has such large strands that it's SUUUUUPER stiff for working with in tiny spaces like that. Plus, the cheeeeep thermoplastic insulation on it, melts under the heat of soldering, and makes a giant blobby mess; and is real thick besides, which makes it that much less likely that it'll jam into tight connector cavity spaces.

I would not under any circumstances "file them down bright". You'll see when you get there: those pins are SMALL. Plus, they have plating to minimize corrosion, and the base metal underneath will corrode about 10 times faster than the plating did, rendering that a VERY short-term band-aid. If they're bad, just replace em.

Mouser ships same or next day of order so you'll probably get whatever you order within just a few days. Pretty sure their main warehouse is in TX butt they have others, no idea which one(s) they stock Aptiv in.

IF I can source some Metripack Pins

IF I can ... stuff them into stock connector

I think at the fuse/relay block end, you can solder a 12 gauge to the underside of the terminal, if you're real careful, and if your wire is something better than generic parts store "primary wire". That stuff has such large strands that it's SUUUUUPER stiff for working with in tiny spaces like that. Plus, the cheeeeep thermoplastic insulation on it, melts under the heat of soldering, and makes a giant blobby mess; and is real thick besides, which makes it that much less likely that it'll jam into tight connector cavity spaces.

I would not under any circumstances "file them down bright". You'll see when you get there: those pins are SMALL. Plus, they have plating to minimize corrosion, and the base metal underneath will corrode about 10 times faster than the plating did, rendering that a VERY short-term band-aid. If they're bad, just replace em.

Mouser ships same or next day of order so you'll probably get whatever you order within just a few days. Pretty sure their main warehouse is in TX butt they have others, no idea which one(s) they stock Aptiv in.

Trending Topics

#8

TECH Apprentice

Thread Starter

Maybe simpler, and more direct to leave the stock wires alone and intact, not mess with the connector, and just stuff my pair of 12 gauge pump POWER and GROUND wires through the little fuel tank PRESSURE sensore port.

There's a MAP sensor there, and I have no reason to Log fuel TANK pressure.

. Will JB Weld be a good bet for sealing a 1/4 hole in plastice fuel tank HAT ?

There's a MAP sensor there, and I have no reason to Log fuel TANK pressure.

. Will JB Weld be a good bet for sealing a 1/4 hole in plastice fuel tank HAT ?

#9

Iunno... it's FUEL, and mixing fuel and the possibility of an electric spark kinda gives me the *******, butt that's just me... I'd stick as close to the factory setup as I could if it was mine, while finding a way to upsize the wire in the most sanitary means possible, if I was doing it. See what connector your truck has and go from there. Without knowing your personal situation, I can't imagine taking on projects of this sort, without alternate transportation; in which case, a day or 2 waiting on parts once you know what you're actually working on, isn't the end of the world.

The following users liked this post:

Fullpower (07-11-2024)

Thread

Thread Starter

Forum

Replies

Last Post

Bgbldodge

Tuning, Diagnostics, Electronics, and Wiring

20

02-08-2023 01:55 PM

cams 98 silverado

GMT 800 & Older GM General Discussion

18

03-23-2010 07:13 AM